The “nuts and bolts” of success

A manufacturer and distributor of metal fasteners and cold-formed parts in the Philippines is now reaping the rewards of CBI coaching by exporting its products to Europe.

Global player

Fasteners Incorporated is the name of a family business started up in a Manila backyard in 1964. By the mid 2000s it had grown to become the country’s largest metal-fastener manufacturer, distributor and exporter, but it wanted more, for both itself and its employees. It wanted to become a global player, by exporting to Europe.

Strength to strength

Between 2008 and 2010 the company tried to break into the EU market on its own, but it didn’t enjoy much success because it didn’t really know how to interpret and use market information, concedes its Sales and Marketing Director Maynard Uy. Then, between 2013 and 2016, it participated in a CBI Export Coaching Programme (ECP), since when it has gone from strength to strength.

Gain trust

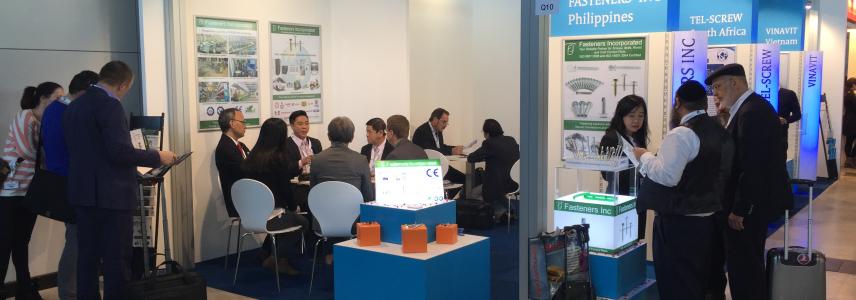

The process of gaining EU market entry was key to the success of the ECP, explains Uy. “Among other things, we learned about the differences between doing business in various European countries. CBI also taught us that if you want to do business in Europe you must first gain clients’ trust. The ECP also stressed how important it was to attend trade fairs. And the support provided by CBI expert Peter Lichthart in all this was invaluable; he helped us in an operational context and took us to new levels of manufacturing.”

Increased exports

Since participating in the ECP, Fasteners has increased its exports to Europe substantially. “This started in 2014 and 2015 when we received modest trial orders. But thanks to what we learned, and because we kept ourselves visible on the market, our exports to Europe increased significantly last year. Also instrumental in this was a CBI-sponsored tour of 10 companies in the Netherlands and Germany last September.”

Corporate Social Responsibility

CBI also stressed the advantages of Corporate Social Responsibility (CSR), says Uy, who concedes that prior to participating in the ECP employee retention was poor. Now, in addition to giving its employees housing, dormitory facilities and access to personal development and education programmes, the company also uses recycling, waste-water treatment and pollution-control systems in its manufacturing operations.

Substantial investment

Uy feels that employee motivation is now higher and the company is much more efficient than it was. All these improvements have allowed it to make a substantial investment in new and bigger production and quality-control machines. “In late 2016 we started up 24-hour operation and we have even become more competitive in our local markets,” he insists.

Paying off now

In conclusion, CBI expert Peter Lichthart explains that in 2017 Fasteners will participate in Europe’s biggest trade fair: the Fasterner Fair in Stuttgart, this time without the aid of CBI. “They have learned how to do it for themselves,” he says. “It is so important for companies to maintain a presence in the market, especially when it comes to visiting trade fairs and prospective clients. CBI trained Fasteners to first focus on building relationships before trying to secure orders. After three to four years of very hard work it is now starting to pay off.”