The best chocolate comes from curiosity and customised protocols

Good chocolate starts with a good genetic variety of cocoa beans. But the post-harvest process is when producers can get the best out of their beans and have the most influence on their final product. As part of the Connecting Central America project, CBI helps participants fine-tune this process. CBI also gives advice on new tools and techniques. Rios de Agua Viva, a cooperative in Nicaragua, explains how the project helped it become competitive and sell its cocoa beans to high-end clients.

Understanding the process

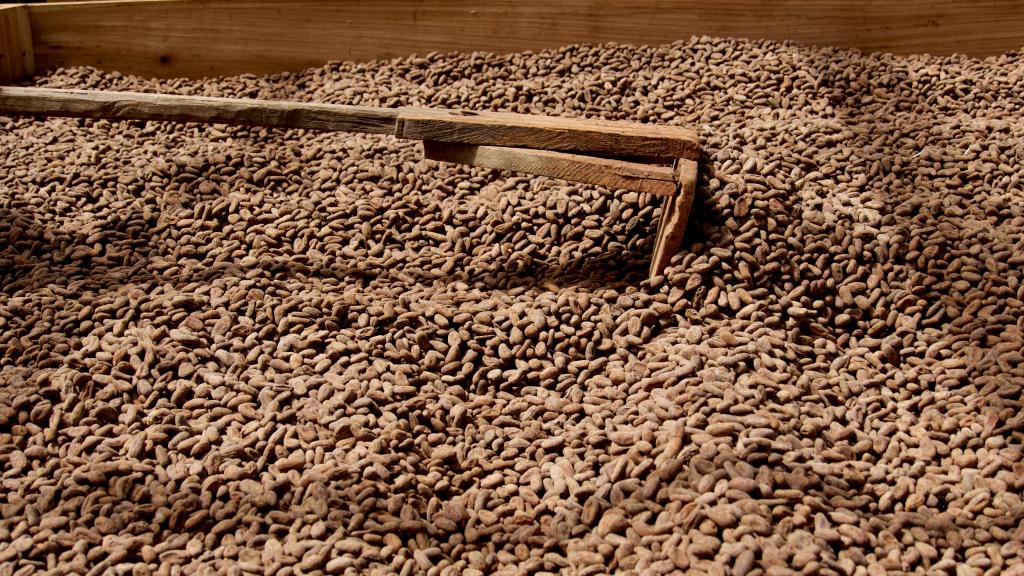

Cacao is what experts call the raw bean used to make the cocoa products we know and love. But before raw cacao can be turned into delicious chocolate, it must go through 3 steps: fermenting, drying and roasting. Small differences in temperature, humidity and the duration of each stage have a big effect on the final product.

Jörn Berger, CBI’s cocoa and chocolate consultant in Central America, explains why it is so important that companies understand these processes and learn to fine-tune them. “Farmers in Central America already have a great genetic base to work with,” he says. “But the post-harvest process can either destroy the flavour of the cocoa beans or bring out the best in them. To get the most refined flavour, you need to be curious and understand what the bean needs. We train participants to ask themselves questions like: How will changes to the protocol affect the flavour? And, what flavours are premium chocolate brands looking for?” These questions seem simple at first, but studying protocols and making changes can be a big investment for companies. Still, several participants have already profited from making changes to their protocols.

One such participant is Rios de Agua Viva, a cooperative in Nicaragua that buys cocoa beans from 500 small-scale farmers. Luis Alexander González is part of the management team. He explains that the company used to have a standard approach. He says, “Every 15 days, we would buy fresh cocoa pods from the farmers and take them back to our centre. There, we would ferment and dry them in bulk. We had been doing this for 14 years. Until recently, we only followed one post-harvest protocol that our local client had asked for. It was a common industry protocol, but it did not bring out the best in our organic cocoa beans.”

Small changes make a difference

In 2018, Rios de Agua Viva joined the Connecting Central America project. Luis Alexander recounts how he and his colleagues learnt about different protocols, sensory evaluation and clients’ wishes. “The first step was a consultation and workshops with CBI’s experts,” he explains. “We learnt to sample cocoa liquors and understand how the post-harvest process brought out the different flavours we were tasting. Then, CBI took us to trade fairs to meet with potential clients. Buyers explained what they were looking for and how they wanted us to ferment or roast the beans. We realised that premium brands would be willing to buy our product if we started to do things differently. This led to us implementing changes in the protocol and infrastructure at our centre.”

Luis Alexander says the cooperative now offers potential buyers up to 6 different samples. Each of the samples goes through a different post-harvest protocol. “Based on CBI’s recommendation, we now use fermentation boxes. This allows us to have more control over the outcome. We are also in the process of creating a tasting laboratory with our own tasting panel.”

Rios de Agua Viva is already experiencing the benefits of these investments. “Because of these changes, our first export was to a premium French chocolate brand. This is a great achievement. It is also encouraging for the farmers we work with. They see that the changes benefit them, so now they are more willing to participate in other improvement projects.”

Competing with the best chocolate makers

Jörn highlights the importance of CBI’s coaching. “Central America offers cocoa beans with excellent genetics. The beans deserve to be treated in the best way possible,” he says. “When producers understand how to do this, they can compete with the best chocolate makers in the world. In such a competitive market, they need to be able to discuss cocoa quality, quantity and prices. Having the right tools and skills means they can produce higher quality products. It also means they better understand what to offer high-end clients and what prices benefit the farmers they work with.”

More information

Would you like to see Rios de Agua Viva staff at work? Take a Virtual Farm Tour.

For more information on participating companies’ achievements, visit the Connecting Central America Facebook Community.

Are you a European importer interested in products from Costa Rica, Panama, Nicaragua, Guatemala, El Salvador or Honduras? Please contact Programme Manager Daphne ter Braak for more information or to meet with the suppliers in this project who are being trained to export to Europe.

The European Union (EU) co-finances the Connecting Central America project. The Secretariat for Economic Integration of Central America (SIECA) coordinates it. This project is part of the Central American Regional Economic Integration (INTEC) project.