Entering the European market for coats, jackets and blazers

Coats, jackets and blazers require special manufacturing skills that are not available worldwide. China is still the largest exporter to the EU in this product category. Other countries in South-East Asia, such as Bangladesh, are also focusing on this product category, but they primarily do volume orders. The market for coats, jackets and blazers is currently seen as a ‘sellers’ market’, as demand is outgrowing supply. European buyers have difficulty finding good suppliers and are interested in discovering new sourcing destinations.

Contents of this page

- What requirements must coats, jackets and blazers comply with to be allowed on the European market?

- Through what channels can you get coats, jackets and blazers on the European market?

- What competition do you face on the European coats, jackets and blazers market?

- What are the prices for coats, jackets and blazers on the European market?

1. What requirements must coats, jackets and blazers comply with to be allowed on the European market?

If you want to sell coats, jackets and blazers on the European market, you need to comply with several requirements. Some are mandatory, whether they are legal requirements or not. Others are voluntary, but meeting them can give you a competitive advantage. Some requirements only apply to certain niches in the market for coats, jackets and blazers.

What are the mandatory requirements?

There are several legal requirements for exporting coats, jackets and blazers to Europe, including requirements regarding product safety, the use of chemicals (REACH), quality and labelling. The EU Access2Markets online helpdesk can help you identify your product code to get a list of applicable legal requirements.

Follow these steps to ensure that your product complies with the relevant legal requirements:

- Product safety. Make sure your product complies with the EU’s General Product Safety Directive (GPSD: 2001/95/EC). If your buyer supplied the product design, it is their responsibility to guarantee it is legally safe for consumers to use.

- Use of chemicals. Make sure you comply with the EU’s REACH Regulation. This legislation restricts the use of chemicals in apparel and trims, including certain Azo-dyes, flame retardants, waterproofing, stain-repelling chemicals and nickel.

- Use of restricted substances. Ask your buyer if they use a Restricted Substances List (RSL). These are often inspired by the guideline on safe chemical use from the Zero Discharge of Hazardous Chemicals (ZDHC) foundation. Download the ZDHC Conformance Guidance here.

- Labelling. Specify the material content of every item that you export to the EU, in accordance with EU Regulation 1007/2011. Check the EU Access2Markets online helpdesk for information about how to do this.

- Intellectual property. Do not violate any Intellectual Property (IP) rights and do not copy designs or share designs with other buyers. If your buyer provides the design, they will be liable in case the item is found to violate a property right.

Special requirements for children’s wear

The EU has a specific standard for the safety of children’s wear. This standard contains requirements to ensure that cords and drawstrings are placed safely on apparel for children up to 14 years old. This is to avoid strangulation and choking hazards.

Additional regulation on the use of chemicals

Some EU countries have additional national regulations for specific chemicals. For example, Austria, Finland, Germany, Norway and the Netherlands have specific regulations for formaldehyde in textiles. Austria, Denmark, Germany and the Netherlands also have specific regulations for PCP, while Germany also has regulations for dispersing dyes in textiles. Switzerland has its own regulation on chemicals, the ORRChem.

Non-legal mandatory requirements

In addition to the legal requirements mentioned above, buyers may have created non-negotiable terms and conditions for their suppliers. These may apply to sustainable production (and the certifications to prove this), quality control or payment terms.

Sustainable production

Most buyers in Europe are increasing their demands for sustainable production and social responsibility. At the very least, buyers will expect you to open your factory doors for them, so that they can inspect your factory. Additionally, you may be asked to comply with certain independent standards for responsible production or sustainable materials.

Supply chain transparency is a key focus point for the European apparel industry, motivated in part by ever stricter laws on both EU and national levels. For instance, the EU’s new Corporate Sustainability Reporting Directive (CSRD) will require all large European companies, from 2023 onwards, to disclose how they manage social and environmental challenges. Transparency means you should disclose information about your own operations to buyers, but also help them to gain as much insight as possible into their (and consequently your) entire supply chain, all the way to the production of raw materials.

Furthermore, buyers in Europe are increasingly demanding recycled content in their items. This is in line with the new EU Regulation that aims to promote a ‘circular economy’. This includes new directives concerning the durability of textile products and a ‘right to repair’ for end consumers. This is particularly relevant for the use of recycled polyester in coats, jackets and blazers.

The ideal situation for European brands and retailers would be to ‘close the loop’ in their value chains. This means having end consumers return worn items. The items can then be:

- Processed into new input materials to produce new styles;

- Repurposed, remanufactured, refurbished or repaired to be resold as second-hand products (a fast-growing market in Europe).

Table 1: Popular standards among European buyers

| Recycled content | Harmful substances and organic production | Social compliance |

| The Recycled Claim Standard (RCS) tracks recycled raw materials through the supply chain using the chain of custody requirements of the Content Claim Standard. | Standard 100 by Oekotex® | Amfori BSCI (Business Social Compliance Initiative) is the most popular (and often only) certification that European buyers will require. |

| The Global Recycled Standard (GRS) is a product standard that incorporates recycled material verification, including social and environmental responsibility criteria, as well as chemical management. | EU Ecolabel | WRAP (Worldwide Responsible Accredited Production) |

| BCI (Better Cotton Initiative) | SEDEX | |

| GOTS (Global Organic Textile Standard) | ETI (Ethical Trade Initiative) | |

| Bluesign® | SA8000 | |

| ISO 26000 | ||

| FWF (Fair Wear Foundation) | ||

| Fair Trade |

Tips:

- Check the free CSR Risk Check database to discover the social and environmental risks associated with apparel production in your country and ways to manage them.

- Provide buyers with as much information on your product as possible. The more information you can give about the origin of your materials, the better.

- Read more about how to comply with transparency requirements on the websites of the Clean Clothes Campaign and Human Rights Watch. To see how European brands are doing, check the Fashion Revolution’s Transparency Index.

- Check the Open Apparel Registry. Many European companies publish the names of their suppliers there.

- Read this article on the website of the Ellen MacArthur Foundation for an overview of circular strategies and best practices.

- Search online for documents created and published by brands outlining their expectations of suppliers regarding CSR (Code of Conduct) or use of chemicals (RSL - Restricted Substances List).

- Discover how your factory scores on social performance by filling in the BSCI self-assessment.

Acceptable Quality Limit (AQL)

To guarantee product quality, your buyer may set an AQL (acceptable quality limit). This is the lowest quality level that is still tolerated. For instance, AQL 2.5 means that your buyer will reject a batch if more than 2.5% of the whole order quantity is defective, measured over several production runs.

Packaging requirements

In most cases, your buyer will give you a manual with instructions on how to package the order. If you agree with your buyer that they will clear customs in the country of import (which is the norm in the apparel industry), it is their responsibility to make sure the instructions comply with EU import procedures. Your buyer will appreciate any efforts you make to reduce the environmental impact (and financial cost) of packaging materials.

Payment terms

For a first-time order, European buyers may agree to a down payment (e.g. 30%). They will pay the remainder (70%) after the order has been completed. The safest payment method for you as a manufacturer is the LC (Letter of Credit). An LC obligates a buyer’s bank to pay the supplier when both parties meet the conditions they have agreed upon. However, many buyers no longer favour LC payments, as this will block their cash flow. Be aware that LCs do not offer financial protection against bankruptcies!

For any further orders, most European buyers will ask for a TT (Telegraphic Transfer) after 30, 60, 90 or sometimes even 120 days. This means you as a manufacturer finish the production and hand over the shipment to the buyer, including the original documents, before payment is due. The payment will be made after the number of days you have agreed with the buyer. This is a risky payment agreement because you are taking the full financial risk.

The buyer manual

When you do business with a European buyer for the first time, they will typically give you a contract and/or a manual to sign. By signing the contract, you confirm that you will comply with all the listed requirements. This means you will be held accountable in case of a problem after the delivery of an order. Complying with REACH can be especially challenging. For small orders, most European buyers will not require testing, but if illegal chemicals are discovered after delivery, you will bear all the costs involved.

Tips:

- Always ask buyers for their buyer manual, which should include all legal and non-legal requirements, including product performance standards, labelling, sizing, quality & safety assurance processes and terms of business.

- Read the CBI study on buyer requirements for an extensive overview of the legal, non-mandatory and niche requirements you will face as an exporter to Europe.

- The COVID-19 pandemic and its effects have shown the negative impact of extended payment conditions for manufacturers. Try to negotiate a down payment for every order and a balance payment before handover. This reduces the risk of cancellation.

- Traditionally, large retailers would place orders for coats and jackets in November and December, followed by brands in February. Now, many European buyers are placing their orders 2-3 months earlier, in response to recent global supply chain problems and the resulting late deliveries. Try to adjust your planning accordingly.

- Do not take financial risks with new buyers. Insure your orders via an insurance company or insist on a Letter of Credit.

- Never agree to comply with requirements you cannot realistically meet. Always be ready to negotiate a workable solution with your (existing or potential) buyer.

Figure 1: The down jacket is still a popular style in Europe

Photo by Luke Porter on Unsplash

What additional requirements do buyers often have?

In addition to non-legal but mandatory requirements like standards and certifications, there are many value-added services that European buyers either implicitly expect or highly appreciate from their preferred suppliers. The requirements will differ from buyer to buyer.

Product design and development

European buyers are always looking for special designs, materials or production methods that will help them stand out in the market. They increasingly expect preferred suppliers to showcase regular design collections with original designs and fabrications and to incorporate new techniques and technologies for garment construction into those collections.

In recent years, there has been a blurring of formal styles and functionality with the emergence of woollen coats in utility styles and more formal coat and jacket styles with functional and technical fabrications and features. Below are some interesting innovations and functionalities that have been applied to coats, jackets and blazers across various sub-categories entering the European market:

- Seam sealing/taping

- Stretch zones

- Articulated/reinforced areas of garments

- Water resistant and water-proof materials and finishes

- 2-way front zippers

- 3-in-1 jackets/coats

- Adjustable hoods, waistbands and hems

- Detachable hoods

- Washable blazers

- Breathable/moisture permeable fabrics

- Handwarmer pockets

- Media pockets

- Zip-out inner jackets

- Chin flaps, storm flaps and wind flaps

- Integrated cuffs

- Biodegradable fabrics

- Body-mapping insulation (places insulation where it delivers most benefit)

- Down contour construction (allows down to form to the body to enhance thermal performance)

- Insulation with improved performance with moisture

- Reflectors

- The use of recycled polyester

- Recycled down/synthetic insulation

- PFAS-free finishes

To ensure quality, functionality and/or environmentally respectful production methods, buyers may require you to source certain raw materials from a preferred supplier. Examples for this category include:

- DuPont for Lycra®

- Gore for Gore-tex™ and Gore-tex Infinium™

- ECONYL® for regenerated Nylon or Waste2Wear® for PET (recycled PET)

- Polartec for a range of performance fabrics including Power Air ™ and Power Shield®

- Primaloft for insulations and performance fabrics including PrimaLoft ® PURE ™

- YKK for AquaGuard® water-repellent zippers

- CORDURA® for reinforced areas of garments

- Teijin for ECO CIRCLE ™ fibres (recycled polyester fibre made of used polyester products)

- Framis for heat-sealed tapes

Popular styles

Styles that are currently popular on the European market for coats, jackets and blazers include the down jacket, softshell jacket (sometimes in combination with down), baseball jacket, kimono, woollen bathrobe, raincoat, packable jacket (which can be folded into a bag), teddy coat, faux-fur and faux-leather jacket, quilted jacket and parka.

Transparency and communication

Smooth communication is an implicit requirement of all buyers. Always reply to every email within 24 hours, even if it is just to confirm that you have received the email and will send a more elaborate reply later. If you have a problem with a production order, immediately notify the customer and try to offer a solution. Create a T&A (time and action) for every order and share it with your buyer. This will help you to manage expectations, monitor progress and is the best guarantee for on-time delivery.

Tips:

- Be proactive and prompt in your communication. Provide your buyer with short text, photo or video updates using WeChat, WhatsApp or Signal. To make free video calls (you only need an Internet connection), try Skype or Google Meet. Register/document all confirmations to prevent any unclarity in a later stage.

- Your buyer may expect cost transparency for every product and order, including a full cost breakdown. Check the CBI study How to calculate the cost-price of an apparel item? for background information and tips about how to calculate costs.

Flexibility

Many factories focus on getting convenient orders: simple designs, large quantities and long delivery times. However, if you want to start a business relationship with a European buyer, be prepared to accept small and/or complicated orders first. There is only a limited group of European buyers that do big volume orders. Even the ones that do will want to test your factory before giving you large, easy orders. Beware at the start that a buyer will not continue placing only difficult orders with you and convenient orders elsewhere.

Expect a European buyer to require in their first order:

- High material quality and impeccable workmanship;

- Order quantities below your normal minimum order quantity (MOQ);

- A price level that is lower than you would normally accept for small quantity orders.

Niche requirements

Although considered a single category, from a manufacturing point of view coats, jackets and blazers differ greatly. Manufacturing wool/wool-blend coats requires a specific manufacturing set-up that includes inline ironing capabilities at each step. Many casual jackets require special finishing or washing while outdoor jackets often require seam-taping capabilities. Blazers are constructed garments and are usually produced in suit factories.

Sustainable apparel

An increasing number of European end consumers from all regions are willing to pay more for products that are produced sustainably. There is a distinct preference among middle to high-income consumers for sustainable and chemical-free materials. Large fashion retailers in the low to mid-price segments such as H&M, Zara and M&S include organic and recycled options within their ranges at affordable prices. At the same time, a high number of middle-segment and premium brands are focusing more and more consistently on these materials.

Active lifestyle consumers

Various brands specialise in active and outdoor wear (jackets) to target a growing segment of consumers that participate in active outdoor sports or have an active lifestyle. Some fashion brands and retailers in the low to middle-fashion segments offer collections of fashion jackets with basic additional performance functionality (for instance a down filling or water resistance). Many active lifestyle consumers across price/quality segments are willing to pay a higher price for a high level of functionality and/or sustainability.

Adaptive apparel

Adaptive coats, jackets and blazers require the use of innovations that help consumers put garments on and take them off more easily. For example, innovations in garment fitting and garment fastenings, such as magnetic closures and Velcro instead of buttons and zippers. Use materials with special properties such as soil resistance, odour repellence or crease resistance. Read more in the CBI study Exporting adaptive apparel to Europe.

Workwear

In addition to the General Product Safety Directive, the EU has laid down specific health and safety standards (EU Directive 2016/425) for the design, manufacturing, material use, testing, and user instructions concerning protective wear, or ‘personal protective equipment’ (PPE). Read all about the specific buyer requirements for workwear in the CBI study Entering the European market for workwear.

Tips:

- Have a well-defined sustainability policy in place and position yourself as a sustainable, ethical supplier. Reflect this in your marketing and storytelling.

- Every brand has its bestsellers. These are styles that sell well and will only be adjusted minimally for subsequent seasons. To find out what a brand’s bestsellers are, check multi-brand platforms such as Zalando or Asos which explicitly advertise items that sell well.

- Monitor trends and developments in technologies and manufacturing processes in your product area by visiting trade shows and events.

- Establish an internal raw materials (yarn and fabric) function to ensure that your company is always at the forefront of new innovations.

- Depending on your product segment, consider investing in in-house washing/finishing, seam sealing, printing, embroidery equipment and/or design to better control quality and speed to market.

2. Through what channels can you get coats, jackets and blazers on the European market?

Advances in technology and communication have enabled manufacturers to supply directly to brands and retailers or even end consumers all over the world, rather than through intermediaries. This may result in higher profit margins for manufacturers, but it also requires a higher service level, for example in terms of material sourcing and development, trends research and design, shorter lead times, flexible MOQs, sales forecasting and logistics. Always do your research and choose a sales channel that matches your capabilities.

How is the end-market segmented?

The market is primarily segmented based on price/quality levels. Distinctive product usage segmentation also exists within the coats and jackets category.

Table 2: Market segmentation

| Consumer type | Price level | Fashionability | Material use | Functionality | Order Quantities |

| Luxury consumers | Very high retail prices | High comfort, fashionable designs | Highly innovative, luxury and/or sustainable materials | Very high requirements regarding functionality and design | Low order quantities |

| Middle and upper- middle market consumers | Medium retail prices | On-trend styling | Good quality, sometimes sustainable materials | Medium requirements regarding functionality | Medium-high order quantities |

Price-conscious consumers

| (Extremely) low retail prices | Basic styles | Medium to low-quality materials | Low functionality | High order quantities |

Source: FT Journalistiek

Luxury consumers

Luxury consumers shop at brands and retailers such as Zegna, Burberry, Max Mara, Moncler, Norrona and Helly Hansen. These consumers expect their clothing to represent a strong brand image and the latest fashion trends, with a focus on maximum comfort. Brands in the luxury market require top-quality materials and manufacturing, the latest technical innovations and highly comfortable designs.

Middle and upper-middle market consumers

The middle market consists of middle and upper-middle market consumers. In this market, lifestyle brands such as Scotch & Soda, G-Star Raw, Massimo Dutti, Asket and PME Legend sell collections created around a brand image and offer a good-quality products for mid-level prices. Products must have the look and feel of a high-end product, but retail prices are lower and can even be substantially lower. Brand images in this segment are increasingly centred around sustainability.

Price-conscious consumers

The budget market includes companies such as H&M, Jack & Jones, Only & Sons, Vero Moda, Pull & Bear, Primark, Decathlon, Monoprix and C&A, which cater to the price-conscious consumer. Volumes are high but prices are low and competition is fierce in this market segment, both with regard to retail and manufacturing. Supermarkets and hypermarkets in the 6 key EU markets offer a range of basics at very competitive prices.

Tip:

- Focus on adding value for higher segments that offer more margin opportunities. If you offer high-quality, sustainable products, make sure your products are fashionable and differentiated in some way.

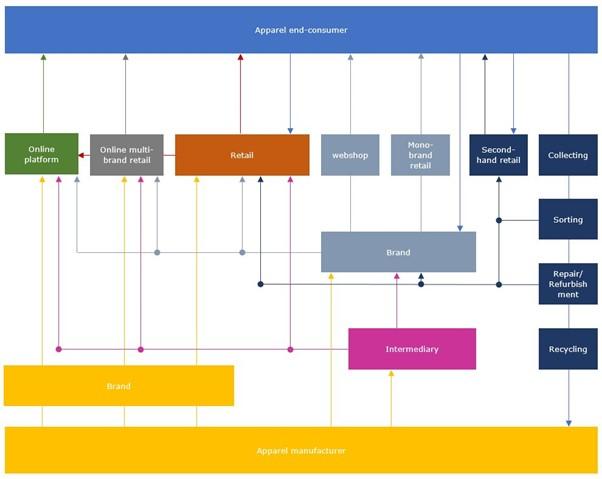

Through what channels does the product end up on the end-market?

There are various channels through which products end up on the European market. Some suppliers and buyers use multiple channels in parallel to take advantage of opportunities and minimise risks. The choice of channel may depend on factors such as product category competitiveness, innovation level or end market. Each type of buyer requires a specific approach. Always try to find out in what part of the value chain your buyer operates, what challenges they face and how you can contribute to their sales strategy.

- Intermediaries such as agents, traders, importers, private label companies and full-service vendors sell your products to buyers up the value chain. They are price-focused and require flexibility in quantities and qualities. Some are located near or in producing countries and primarily do sourcing and logistics. An example is Li & Fung. Others, such as Dewhirst, work from Europe and focus more on market research, design and stock-keeping. Their service level determines the commission rate they charge.

- Independent brands typically develop a collection 12 months in advance. You will need a large sample room as brands require salesman samples (SMS) of each collection style. Every sample needs to be actual: meaning it must look exactly like the product will look in the shop, with branded hangtags and accessories. It may take many months before orders are placed. This sales process can cause delays to production as well as uncertainty in forecasting quantities, including for raw materials.

- If you want to sell to retailers, the biggest names in coats, jackets and blazers include H&M and C&A. Retailers can place an order relatively easily as they only need 1 development sample for order confirmation. Order quantities are usually high, as is price pressure.

- Online multi-brand retailers such as Zalando, Asos, Yoox and LYST sell existing brands and develop their own private collections, mostly value brands. They can detect market interest very quickly and will immediately react based on sales data. Usually, such companies first place a small test order. If the item sells well, they will place the actual production order. Fast delivery is a must.

- The growing second-hand market in Europe is serviced by online platforms such as vestiairecollective.com, vinted.com, depop.com or national websites such as marktplaats.nl (the Netherlands). Some brands and retailers have launched their own second-hand platforms, such as Sellpy by H&M.

- If you want to target European end consumers, try selling via platforms for independent brands such as Alibaba, Wish, Amazon and Wolf & Badger. Most online consumers can be found in countries in Europe’s northwest. You will need to invest in a web shop, stock, order management and customer service. Your biggest challenges will be return policies and a lack of brand awareness, making it difficult to find buyers outside the budget market.

Tips:

- Visit a trade exhibition. Find out how other manufacturers are presenting their companies, capabilities and products based on their target buyers.

- Attend specialised fashion events within Europe. Talk to exhibiting brands about their sourcing models and requirements.

- Research the market at the following trade fairs: Pitti Uomo (men’s fashion trade show in Florence, Italy), Premiere Vision (textile and fashion sourcing fair in Paris, France), Texworld (fabric and apparel sourcing fair in Paris, France), Modefabriek (fashion trade show in Amsterdam, the Netherlands), Copenhagen IFF (Fashion trade show in Denmark) and Jacket Required (UK).

- If you plan to meet an existing or potentialbuyer at a(n online) fair, check what collections they have, buy 1 or 2 items and prepare matching or even improved samples. Also work out the costing before introducing your company and your samples to a potential buyer.

- You can find intermediaries specialised in outerwear and blazers by using an online search engine. Use keywords such as ‘full service’, ‘garment’ or ‘outerwear’ + ‘solution’. Trader’s websites usually show the brands they work with.

- Be on top of new technical developments in the market. Be an advisor in addition to a producer to create a competitive advantage.

Figure 2: Apparel market value chain

What is the most interesting channel for you?

The best sales channel for you largely depends on your capabilities and the service level that you can offer.

Intermediaries

Intermediaries are the most adventurous type of buyer and are usually the first to investigate new sourcing destinations and factories. By working with this type of buyer, you will have access to many different buyers up the value chain and you can learn how to service them by following their instructions. There are different types of intermediaries.

- Agents are located near the site of production and their traditional role is to act as a bridge between buyers and manufacturers. All responsibilities and risks are borne by the factory. The agent usually charges a commission (up to 10%) based on a percentage of the total cost of goods purchased. The role of the agent is becoming less important as the industry moves towards more direct sourcing.

Li & Fung is the garment industry’s largest and most dominant agent. Although it is a ‘middleman’, it continues to be successful because it puts customer service at the heart of everything it does. In addition to sourcing, it provides important supply chain support services including logistics, cost management, production monitoring and design support. Its size allows it to have greater influence over suppliers, enabling it to deliver consistently on its promises to the customer.

- Full-Service Vendors (FSVs) are usually located in Europe to be close to the market. Many also have offices in the production regions to gain greater control over product development and guide the factories during production. The price paid by the buyer includes the FSV’s margin (up to 20%). The FSV bears most of the risk for the manufacturer and is increasingly taking on responsibilities on behalf of the buyer, including sales forecasting and holding inventory.

Each season, the FSV designs collections for its buyers and sends tech packs to the factory. Once complete, the FSV designers and sales representatives will visit the buyer to present the collection. Some styles will be dropped, others ‘tweaked’, before creating fit samples ahead of bulk production. The factory is paid for all samples produced. Factories are increasingly becoming FSVs as they increase their skills. Similarly, some FSVs have bought factories to provide a full-service solution to their buyers.

The FSV is the most attractive sales channel for small and medium-sized manufacturers in developing countries with little or no export experience. By working with an FSV, you can manufacture products for multiple brands and retailers. At the same time, you avoid the risk and investment associated with direct sourcing. Despite a lower margin compared to producing directly for a retailer or brand, this channel represents a very good learning opportunity for a factory wanting to start exporting to the EU.

Brands

Many brands develop special ‘outlet’ collections. This can be another good entry point for manufacturers to do business with European brands, because the items will have a relatively simple design and order quantities are large. If the buyer is satisfied with the quality of your product and your service, they may ask you to produce items for their mainstream collection.

Retailers

Larger, own-brand retailers and department stores have the biggest market share in Europe. They control all aspects of product design, development, labelling, distribution and marketing. All these factors make them another interesting channel. Many of these retailers have buying offices in production regions to better monitor product development, production and quality. Usually offering high order quantities, they can demand very low prices, costing transparency and strict compliance with social and environmental standards.

Tips:

- Establish a relationship with your country’s trade associations, including garment industry support organisations. They can give you information about programmes and events designed to connect buyers and manufacturers.

- Search online for FSVs using keywords such as ‘full service’ + ‘garment’ + ‘solution’. FSV websites usually show the brands and retailers that they work with.

- Visit tradeshows and look out for suppliers marketing themselves as FSVs.

3. What competition do you face on the European coats, jackets and blazers market?

The most important factors in creating a competitive advantage over manufacturers in other countries in this category are technical knowledge, service level, flexibility to accept lower MOQs, efficiency and beneficial trade agreements.

Price

Coats, jackets and blazers are complex and expensive garments. High production efficiency combined with savings on import duties can significantly increase price competitiveness.

Raw materials sourcing and technical innovation

Being competitive within this segment requires constant innovation in fibres, fabrics and garment construction techniques. Manufacturers that invest in R&D and a fabric sourcing function will be the most important strategic partners for brands in the upper-middle and higher fashion segments. In addition, the growth in demand for sustainably produced fabrics means that manufacturers must source from reliable suppliers who provide total traceability along the supply chain.

Flexible MOQs

Manufacturers need to offer flexibility to their customers in terms of both raw materials and production MOQs. This is especially the case in the premium and luxury segments.

Which countries are you competing with?

Table 3: Competing countries

| Country | Strengths | Challenges |

China

| Technical innovation, high efficiency, excellent customer service and the local availability of fabrics and trims give Chinese manufacturers an advantage over competitors in development countries. | Rising labour and production costs and no General Scheme of Preferences (GSP) that removes import duties to the EU all work against Chinese exporters. China is also facing claims about employing forced labour. |

| Bangladesh | Bangladeshi producers specialise in cheap basic apparel, including fashion coats, jackets and blazers. The country benefits from low production and labour costs and the GSP. | High MOQs, lower technical expertise than China, and more factories need to become compliant with international safety and sustainability standards. |

| Myanmar | The garment industry in Myanmar has grown significantly in recent years and is heavily focused on woven apparel. The country benefits from low production and labour costs, an abundant labour supply and the GSP. | Political instability, a dependence on imported textile raw materials and relatively low productivity. |

Vietnam

| Vietnam’s apparel industry has developed a large capacity and high efficiency levels, thanks to investments from mainly Chinese factory owners looking to benefit from the low production costs and a new free trade agreement with the EU. | High MOQs, lack of local fabrics, accessories and trims and, in general, a lack of capacity. |

Tips:

- Study the countries you will be competing with. Compare their strengths and weaknesses to yours and advertise the competitive advantages of doing business with you. In addition to the GSP, consider factors such as distance to Europe, ease of doing business and transparency.

- Check the freely accessible CSR Risk Check database to discover the social and environmental risks associated with apparel production in different countries, including your own. Use this information to mitigate risks and to advertise the advantages of sourcing in your country.

- Check if and how other countries benefit from the Generalised Scheme of Preferences on the EU’s website on international trade.

Which companies are you competing with?

Due to the higher complexity involved in manufacturing coats, jackets and blazers, production is generally concentrated in well-established factories or factory groups with a high level of knowledge and expertise. Many large Chinese manufacturing groups have shifted part of their supply chains to developing countries to take advantage of lower wage costs, capacity availability and duty-free access to the European market.

Successful local manufacturers in competing countries have positioned themselves as highly ethical, compliant and customer-centric suppliers. They focus on providing value added services to steadily grow their business and expand their production capacity, product scope and customer portfolios.

Some manufacturers have used their knowledge and experience to move up the value chain by opening retail stores or selling their own branded products. This gives them additional valuable insights into consumer purchasing behaviour and trends.

Leverstyle is a large manufacturing group whose history dates back to 1956 when it was founded as a shirt-making business in Hong Kong. The company now produces a broad range of apparel products including coats, jackets and blazers in various facilities in 7 countries (China, Vietnam, India, Indonesia, Cambodia, Bangladesh and Myanmar). It supports its clients with technical knowhow and product development capabilities that it has built up over decades of working with the most discerning designers and brands.

Jiangsu Guotai Huasheng is a subsidiary of the Jiangsu Guotai International Group (one of China’s 500 leading companies) that specialises in import and export. With 7 production units in China and 4 overseas (in Myanmar and Cambodia), Jiangsu Guotai Huasheng is one of the largest Chinese exporters of apparel. Its core product range includes fashion jackets, pants, skirts and dresses, but it also produces knitwear. As part of a large group, Jiangsu Guotai has a high level of vertical integration including yarn, fabric and trims production.

Founded in 1996 and headquartered in Taiwan, Quang Viet Enterprise Co., Ltd is one of the world’s leading suppliers of garments for the outdoor sports industry with operations mainly in Vietnam and China. With a focus on down and padded jackets and high-end technical jackets, the company is Fair Trade certified. This means that it is eligible to manufacture and sell products according to Fair Trade standards. Customers include Puma, Arc’teryx, Norrona and Mammut.

Tips:

- Explore partnerships that can offer market access opportunities and/or raise your knowledge and service levels.

- The ability to source a broad range of quality inputs offers competitive advantage. For manufacturers in countries that enjoy duty preferences to Europe, it is important to understand the rules of origin regarding raw materials and build up an appropriate network of regional and/or Chinese suppliers.

- A high level of quality and service alone will not necessarily lead to growth. A professional approach to marketing and sales is essential. Create a high-quality website in English and communicate your capabilities on a continuous basis by exhibiting at trade fairs and/or through sales representation in Europe.

- Check the free online database Open Apparel Registry. On this website you can find the suppliers of hundreds of European fashion brands, including buyers of coats, jackets and blazers.

- Read the CBI study ‘10 Tips for Doing Business with European Buyers’ to learn how to approach and engage with buyers.

Which products are you competing with?

The European coats, jackets and blazers categories include several interesting sub-categories. In recent years the lines between formal and casual have blurred to some degree, following a wider apparel sector trend which emphasises comfort, convenience and functionality for more active and/or relaxed lifestyles. In each category, there has been a marked shift in the choice of materials used as a result of emerging EU-level and individual brand requirements regarding recycled content and recyclability of garments at end of life.

Blazers

The traditional formal blazer is usually produced with wool, cotton or linen and can be distinguished by a (relatively fixed) number of design variations including:

- Fit (e.g. classic, slim)

- Canvas (e.g. half, full)

- Lapels and collars (e.g. peak, notch, convertible, high/low gorge, reverse collar, rounded notch etc.)

- Pockets (e.g. barchetta, flap, patch, ticket, slanted, straight)

- Stitching (e.g. AMF or pick stitching)

- Vents (e.g. single, double)

- Buttons (e.g. mother of pearl, silver, pewter, brass, Nelson)

- Contrast piping, braiding or trim/other details

- Lining colours/designs

Travel blazers are generally machine washable and wrinkle resistant as they are made from wool blended with polyester or with polyester and elastane. The unconstructed blazer is a more casual style with a looser, softer shape. It has no padding, canvas or fusing and uses minimal lining. A staple in spring and summer, it is often made from cotton, linen or, more recently, hemp combined with linen. Knitted blazers are gaining in popularity. They are similarly unconstructed and offer a look that is at the same time casual and tailored.

Coats

Viscose combined with wool adds a nice drape to the garment and wool combined with polyester can significantly reduce the cost and improve ease of care of the garment. However, there is an emerging trend towards using 100% wool to guarantee the recyclability of the garment at end of life.

The more formal woollen coat can be designed to have a more casual and/or mainstream look by applying military, utility or relaxed styling. It can also include functional/technical features (such as a zip-out inner jacket or wrist gaiters) for convenience and a modern aesthetic.

Jackets

The jackets category is the most highly diversified with sub-categories including fashion, workwear and technical/performance jackets. There is an increased focus on - and innovation in - technical and performance features across all sub-categories, from the water-resistant fashion down jacket to the insulated Goretex wind and waterproof winter ski jacket to the high-visibility, flame-retardant and chemical-resistant safety workwear jacket. The safety workwear segment is highly specialised and heavily regulated.

There is a lot of competition but also collaboration in the technical/performance outdoor jacket space. These brands are particularly environmentally conscious and are increasingly ‘open sourcing’ their key sustainable styles, allowing anyone who is committed to developing sustainable products to access details about raw materials, techniques, processes and materials suppliers. Fashion players such as ASKET are following suit by being transparent about material sources, costing and a breakdown of a garment’s environmental impact.

Tips:

- Explore trends within a trend (e.g. unconstructed blazers or fashion jackets with water-resistant functionality) and present your buyers with seasonal colour palettes, design variations and fabric options.

- Focus on comfortable, high-quality and/or sustainable fabrics to differentiate your offer, especially for mid and higher segments.

- Create and present your own collection of original designs on quality fabrications.

4. What are the prices for coats, jackets and blazers on the European market?

The price of your product, in fashion jargon often indicated as the FOB price (for free on board), is influenced by many factors, such as the cost of materials, the efficiency of your employees and your overhead and profit margin.

The following figure shows the average cost breakdown of a typical FOB price:

Note that these percentages may vary per factory and per order. Some factories accept lower profit margins during off-season periods, or when order volumes are high. In addition, the percentages for labour versus fabrics may differ, depending on the efficiency and wage level of the workforce and the price of the materials. Efficiency goes up and material prices go down when producing large-volume orders.

Retail pricing

Depending on product complexity, materials used, quality levels and branding levels, current retail price ranges (in euros) for key product types in the different price segments are generally as below:

| Product | Budget / value segment* | Middle segment | Premium / upper-middle segment | Luxury segment |

| Long woollen / wool blend coats | 80-180 | 200-350 | 350-600 | 900-9000 |

| Short fashion jackets | 30-80 | 80-120 | 150-300 | 500-1500 |

| Performance / weather proof jackets | 40-100 | 100-200 | 300-700 | 800-2500 |

| Blazers | 30-70 | 70-150 | 160-350 | 400-3500 |

*Does not include the discount segment

Markup

The retail price of an apparel item is, on average, 4 to 8 times the FOB price. This multiplication is the ‘retail markup’. It follows that the FOB price is, on average, 12.5%–25% of the retail price of the product. Exceptions exist. In the budget market, some large European retail chains may sell products for a markup of just twice the FOB price. Retailers mark the FOB price up to account for import duties, transport, rent, marketing, overhead, stock keeping, markdowns and VAT (15%–27% in EU countries), among other costs.

According to Eurostat’s 2020 comparison of retail prices for apparel, of the top 6 European importers of apparel and footwear, France has the highest price level at 107.6 points compared to the European average of 100, followed by the Netherlands (106.1), Italy (101), Germany (98.2) and Spain (92.2). The UK, which is now out of the EU, had a score of 90.7 in 2019. Note that brands and retailers that sell in multiple European countries usually keep prices equal or deviate only slightly from the standard retail price.

Price development

Online commerce and a strong budget segment have made consumers in Europe accustomed to low prices. However, the focus on sustainability and rising costs of materials, production (due to the global COVID-19 pandemic and political instability) and shipping have put manufacturers, suppliers and buyers under enormous price pressure. In the first quarter of 2022, this has resulted in sharply rising European retail prices for many consumer goods. For up-to-date information on retail price inflation in the EU, check Eurostat.

This study was carried out on behalf of CBI by Frans Tilstra and Giovanni Beatrice for FT Journalistiek.

Please review our market information disclaimer.

Search

Enter search terms to find market research