9 tips to go digital in the apparel sector

Since the industrial revolution in the 19th century, machines, electronics and digital computers have made apparel production ever more efficient. Now we are at the start of the ‘5th industrial revolution’ (5IR), in which Artificial Intelligence (AI) is driving the automation of production processes, and is truly merged with human intelligence. The aim is the creation of a value chain that is more transparent, efficient, flexible, cost-effective, creative and sustainable than ever. This report will help you understand digitisation and how you can benefit from it.

Contents of this page

- Familiarise yourself with the most common forms of digitisation

- Know the jargon

- Start by gathering data within your factory

- Grow your business with the help of new technologies

- Familiarise yourself with the many applications of generative AI

- Let experts help you implement new technologies in your production line

- Use Europe’s growing e-commerce industry to your advantage

- Let market data drive your sales strategy

- Maximise your flexibility using digital tools

1. Familiarise yourself with the most common forms of digitisation

Automation of manual labour and digitisation of analogue data is nothing new in the apparel industry. The reason experts now speak of ‘smart’ factories operating in an ‘Industry 5.0’ is the large-scale use of digital data to integrate the different steps in the production process, such as purchasing, inventory management, design, tech pack creation, costing, manufacturing, and sales. The tracking and exchange of data between the software and machines that are used for these processes is what makes a supply chain truly digitised.

There are two different types of digitisation in the apparel industry:

- The collection of manufacturing data. The purpose of this is to improve production efficiency and product quality. This will result in increased profitability and accountability and an overall reduction in costs. It can also be used to improve (and report on) working conditions and reduce environmental impact;

- The collection of market and customer data. The purpose of this is to ensure efficient communication between manufacturers and buyers, on-time delivery (of first and repeat orders) and increased speed to market. Market and consumer data can also save time and costs in the confirmation process. This will result in increased profitability and an overall reduction of costs.

The online approval process

Buyers do not need to be as actively involved in manufacturing as before. The use of online communication tools and the growing demand for small orders and flexible service have digitised the only process that used to involve buyers personally on site: the approval process. Anything from lab dips to fit samples can nowadays be shared online between manufacturers and buyers, taking away the need to visit sites or send samples by mail. This has made the approval process much faster and production times shorter.

Digital innovations are used in every part of the apparel value chain: from the production of raw materials to sales of ready-made products.

Table 1: Digital innovations in every step of the apparel value chain

Value chain tier | Overview of digital innovations |

| Raw material production | For the production of raw materials precision farm management systems such as CropIn or AgroCares are used to optimise cotton growth by use of weather and soil nutrient data and satellite imagery. For synthetic materials digitised input and waste management systems are used to reduce environmental impact and optimise efficiency. Adding marking techniques to raw materials such as Haelixa or FibreTrace enables factories to digitally trace materials back to their origins, making value chains truly transparent and traceable. |

| Fabric making, finishing | In weaving, knitting, dyeing, washing, and finishing, digitisation and machine learning is primarily used to control and reduce inputs (raw materials, energy, water, chemicals); to recycle solid and liquid waste; to measure and predict fabric performance; to control quality and to plan fabric and accessory ordering. Automation can also increase worker safety. A fully automated and closed dyeing and laundry system lowers the exposure of employees to potentially dangerous chemicals and machinery. |

| Manufacturing | An important development in manufacturing is 3D design and prototyping. Designing garments in 3D software makes designers understand fit better, reduces quality issues and eliminates the need to send samples back and forth for approval, saving time and money. In cutting, sewing and finishing, handling takes 80% of production time and cost. Here AI-controlled CNC/CAD/CAM pattern and cutting machines, overhead conveyors and tracking terminals at the workstation improve productivity and reduce energy use and wastage. Online platforms offer fabrics and trims, stock lots and cutting waste. |

| Logistics | Digitising logistics can reduce cost and improve speed and flexibility. The newest tracking solutions such as barcodes, RFID chips and online platforms enable manufacturers to track incoming and outgoing shipments in real time and to track material flow through the factory. Brands and retailers use AI to predict sales of specific products in certain locations, adjusting their inventory accordingly in nearby warehouses. Online platforms offer solutions to consolidate several smaller shipments in one container, reducing costs. Digitisation can also be used to measure and report on environmental impacts of different modes of transportation. |

| Sales | Running a profitable business means you need to constantly analyse sales to your buyer and how the apparel items perform in the end market. Collecting and analysing sales data enables you to optimise product development and stock keeping, maximising sales and liquidity. Sales data include: turnaround speed, colours, returns, fitting, quality, price vs. sales, profitability, trends and sizing. New developments such as digital showrooms and catwalk shows also reduce time and cost when engaging with (potential) buyers. |

| Full supply chain transparency | To secure market and buyer compliant production, full supply chain transparency is required. Organisations are putting more focus on providing the buyer and the consumer with validated data about where and how their products are made. See for instance Tex Tracer, Ecovadis or Ecochain. |

Source: FT Journalistiek

Tips:

- Invest in Enterprise Resource Planning (ERP) software to integrate your planning, inventory, sales, marketing, finance, human resources, and more. Check review platform SoftwareAdvice for a (non-extensive) overview of available ERP systems for the apparel industry.

- For inspiration on how to apply digitisation in your factory, check factories such as Sun Tekstil (Türkiye, use of Artificial Intelligence in production), Hugo Boss (Türkiye, use of AI and tablets for tracking production data) or Daehan (Indonesia, applying Internet of Things to optimise the sewing process).

- Professionalise your material sourcing by developing a supplier’s code of conduct and building your own database of suppliers that meet your requirements. These will be based on your buyers’ requirements and any additional requirements that they might have. Look beyond product and price to certifications, social requirements, product quality, and country of origin (GSP).roduction data) or Daehan (Indonesia, applying Internet of Things to optimise the sewing process).

2. Know the jargon

When you read about digitisation, you may come across different terms, such as ‘(generative) Artificial Intelligence’, ‘big data’ and the ‘Internet of Things’. Often these terms are used interchangeably. What do they mean?

Table 2: Digitisation jargon and its meaning

| (Generative) Artificial Intelligence | Intelligence demonstrated by machines that can sense their environment and perform actions autonomously. In 2023, ‘generative AI’ (gen AI) became a standout trend. This term applies to AI programmes that can be used to generate new (digital) content, including apparel designs. |

| Automation | Technologies that reduce the need for human intervention in factory processes. |

| Big data | The use of Artificial Intelligence to extract meaningful management data from sets of data that are too big for conventional software to manage. |

| Blockchain | Online decentralised data storage system, used to share and verify supply chain information between manufacturers, suppliers and vendors. |

| Digitisation | The increasing use of digital data and automated machines to increase production efficiency and flow. |

| Internet of Things | The network of machines equipped with sensors and processing software, connected to the internet. |

| Machine learning | The capability of computer algorithms to improve their output by learning from inputs (and the associated desired outputs). |

Source: FT Journalistiek

3. Start by gathering data within your factory

The first step on your journey towards digitising your factory does not have to be a huge investment in state-of-the art software or hardware. Highly digitised apparel factories may use expensive machinery, materials and production lines equipped with QR codes, RFID chips, intelligent sensors and cameras connected to computer-controlled machinery using Artificial Intelligence. But remember, digitisation is not an end. It is a means to reduce costs and increase efficiency, using data from the factory floor. That process can start simple.

The basic principle to cost reduction is to track and monitor every cost item in your factory. That can be done by hand by an employee with a clipboard and a pen.

To reduce costs, gather data on:

- Working hours. How many hours are your employees working for you?

- Effective working time. How long are they effectively at work?

- Purchasing. Can you get better conditions by consolidating relations with your supplier(s)?

- Stock management. What do you have in stock? What is the value and lead time of each item? Can you minimise stock? Ideally, try to have materials in your warehouse 3 days before production starts;

- Energy consumption. Consider investing in energy saving machinery and lighting to save costs and reduce environmental impact.

To improve efficiency, gather data on:

- The production line balance. How is the flow? Are there hick-ups in the production line?

- Employee motivation. What are their ambitions? What is the retention rate, sick leave, (living) wage level? What can you do to improve employee motivation?

- Working procedures. Are there clear working procedures? Are they properly communicated? Does everybody understand them?

- The competition. What are they offering their employees? How are their wages, secondary benefits?

Tips:

- First try to optimise your production efficiency with the means you already have available in your factory (expertise, machinery, factory set-up, software).

- When gathering data on cost items, don’t focus on big cost items only. Cost reduction can also be achieved by saving on many small ones.

- Read this article on Fibre2Fashion. It offers an overview of 15 different strategies that can help you increase production efficiency in your factory.

- Kanban is a much applied and relatively easy reflexive management system focussed on optimising production flow on the factory floor. The basic principles are explained in this article on Apparel Resources.

- Read the CBI report ‘How to calculate the cost-price of an apparel item?’. It offers valuable insights into all cost items involved in apparel production, in addition to an interactive PDF file that helps you calculate the factory price of a single garment.

4. Grow your business with the help of new technologies

The concept of digitisation goes beyond using software to handle your administration, emailing buyers and using computer-controlled cutting or sewing machines. Digitisation is about real-time performance measurement, discovering patterns in the data and using interconnected software and machinery to optimise production, minimising the need for human intervention. There are many technological solutions available. Some are costly, others complicated. Sometimes they are both. Choose the ones that fit your business.

Software

When it comes to software, there are many different systems available that can help optimise your factory management, including integrated Enterprise Resource Planning (ERP) systems, Product Lifecycle Management (PLM) systems, and specific software programmes for anything from stock management, order management and HR management to Customer Relationship management (CRM). New 3D designing solutions can seriously increase your efficiency and flexibility in the communication process with buyers.

Machinery

A truly digitised apparel factory uses software to interconnect ‘smart machines’: from the material warehouse to the sampling room, cutting department, assembly line, finishing department and product warehouse. Companies such as Kuris or Zünd provide the latest technologies in digital cutting techniques, including 3D cutting. Companies such as Juki provide sewing machines that can be digitally linked to a smart factory software system, integrating the cutting and sewing department, optimising efficiency by balancing the line.

Tips:

- When you are looking for a software solution for your factory process, always make sure you choose a method that suits your needs and fits your business. Look at price and service level and find a product that matches your factory size. Most software is modular, enabling you to expand with need. Always ask the supplier to what extent it can be adjusted to your specific needs.

- Don’t settle too quickly for cheap, local solutions. Find solutions that are supported by your international buyers and that have a proven track record. If you are not sure what software solutions to choose for your company, try to ask others in the industry what they are using;

- Check 3D design software providers such as CLO, Gerber or Alvanon to learn about the latest techniques in 3D designing and prototyping;

- When you are considering shifting to 3D sampling techniques, remember that many designers still prefer to draw by hand. Working digitally requires training;

- Watch this short video on YouTube by Juki (sewing polo plackets) and Richpeace Group (automatic sewing machine for attaching zippers) to get an idea of the type of production processes that can be automated.

5. Familiarise yourself with the many applications of generative AI

Artificial Intelligence (AI) was already a well-known term before ChatGPT hugely popularised the use of AI with the launch of its programme in November 2022. ChatGPT and other popular AI tools, such as DALL-E, have made it possible for a wide audience to quickly create text and images with little effort, using ‘generative AI’. Such programmes have interesting applications for the apparel industry too and are already used by brands, retailers, designers and manufacturers worldwide to improve their designs, business intelligence, planning and training.

Table 3: The most interesting applications of generative Artificial Intelligence in apparel production

Apparel design | Generative AI can create designs by analysing massive datasets of previous designs, colours, patterns, and market trends. Tools like OpenAI’s DALL-E or custom-built models are used by designers to generate unique and creative concepts for garments, accessories, or even entire collections. |

| 3D Sampling | Generative AI allows for the quick creation of 3D samples. Platforms such as CLO 3D use AI to generate realistic 3D clothing models that simulate draping, movement, and textures. This reduces the need for physical samples and allows designers to visualise how a garment will look and behave on a variety of body types and environments, speeding up the approval process (see above). |

| Textile and fabric design and production | Generative AI can create new and unique designs for prints and weaves or create complex designs for knitted garments by optimising yarn placement and stitch patterns. |

| Customised apparel | Mass customisation is made possible by generating individual designs based on user preferences and body measurements. Platforms such as Unmade use generative algorithms to let end consumers customise the design, colour, and fit of garments in real time. |

| Sustainable production | Generative AI can optimise material use and minimise waste by suggesting the most efficient cutting patterns for fabric (see below). It can even design clothes to be more durable and timeless, reducing the need for frequent replacements, and promoting slow fashion. |

| Trend forecasting | Predicting and generating future fashion trends by analysing consumer behaviour, social media activity, and historical sales data, is made easier by using generative AI. Tools such as Heuritech or Stylumia use AI to generate insights into upcoming styles, colours, and patterns that will dominate future seasons. |

| Content creation for marketing | Fashion brands use generative AI to create marketing materials, including product descriptions, images, and even entire campaigns. AI can generate content that matches a brand’s values and look, creating promotional items like Instagram posts or lookbooks. Vue.ai, for instance, can automate the content creation process for fashion retailers. |

Source: FT Journalistiek

Tips:

- Use ChatGPT (text) or DALL-E (images) to familiarise yourself with the use of generative AI. These AI tools can be used for free (after creating an account). AI tools specialised for use in the apparel industry usually come at a cost.

- Read this article by McKinsey on the different types of AI, and their most popular applications.

6. Let experts help you implement new technologies in your production line

Establishing a truly automated, digitally interconnected production line requires a lot of expertise. It is not as easy as plugging in a machine and pressing the on button. To what extent your factory can integrate different departments (cutting, sewing, assembly, finishing, etc.) depends on many things. How is your production line organised at the moment? What machinery do you use? How suitable are your machines for digital interconnection? What fits your service level best? These issues are not solved by factories alone.

Often machinery suppliers such as Brother (US), Juki (US) or Jack (China) will provide technical support on site. This means they will send their experts to your factory to install or upgrade software and hardware. They can also help you integrate the machinery in a smart factory (software) system that lets you measure and improve the performance of your production line. This also includes training your staff on how to properly operate the machines and software. Many machinery suppliers work from local offices in production countries.

For more neutral (and usually more general) advice on apparel technology and innovation, try to connect with local institutions. Many production countries have organisations connected to industry associations, universities or technology hubs that can support you in automating the production process. See for example:

- Ethiopian Institution of Textile and Fashion Technology (EITFT);

- Industrial Modernisation Centre in Egypt (IMC);

- Centre Technique du Textile et de l’Habillement in Morocco (CTTH);

- Garment Design Training Services in Jordan (GSC);

- National Institute for Fashion Technology in India (NIFT).

Tips:

- Hire freelance efficiency experts if you do not want to depend on expertise from machinery suppliers. Sometimes they want to be paid based on improved performance, which can be an economical solution. Ask industry associations, international development programmes (CBI, for instance) or fellow manufacturers for referrals.

- Watch this short video on YouTube by machine manufacturer Jack about their analysis of machine utilisation data and how it can be used to improve efficiency.

- Watch this short video on YouTube by machine manufacturer Juki about their solutions for balancing the production line using their smart factory system JaNets.

Figure 1: Hadayana in Jordan uses integrated digital pattern-making machinery in a highly automated production process

Source: FT Journalistiek

7. Use Europe’s growing e-commerce industry to your advantage

Online shopping continues to grow in Europe. According to the EU’s Ecommerce Monitor (2023), 92% of Europeans use the internet and 78% shop online (up from 67% in 2018). The shift to online sales offers several opportunities for manufacturers. First, it opens a sales channel for direct B2C sales in Europe. Second, it offers a wealth of (often freely accessible) data on market preferences and trends, applicable to both B2B and B2C sales.

Business-to-consumer sales

If you want to build your own brand and target European end consumers directly, try selling via platforms such as Alibaba, Wish, Amazon or niche platforms such as Depop or Wolf & Badger for independent brands. Most online consumers can be found in countries in Europe’s northwest, with apparel being the most popular category that people shop for online. You need to invest in a web shop, stock, order management, customer service, and a brand image. Return policies and a lack of brand awareness will be your biggest challenge.

Business-to-business sales

Online multi-brand retailers such as Zalando, Asos, Lyst, Yoox or Aboutyou sell apparel brands and develop their own private collections. These are mostly value brands. Online retailers are data-driven companies, that can detect new trends in the market very fast and will immediately react upon sales data. Usually such companies will place a small test order first. If the item is selling well, they will place the actual production order. You must be able to deliver very fast to service such buyers.

Market intelligence

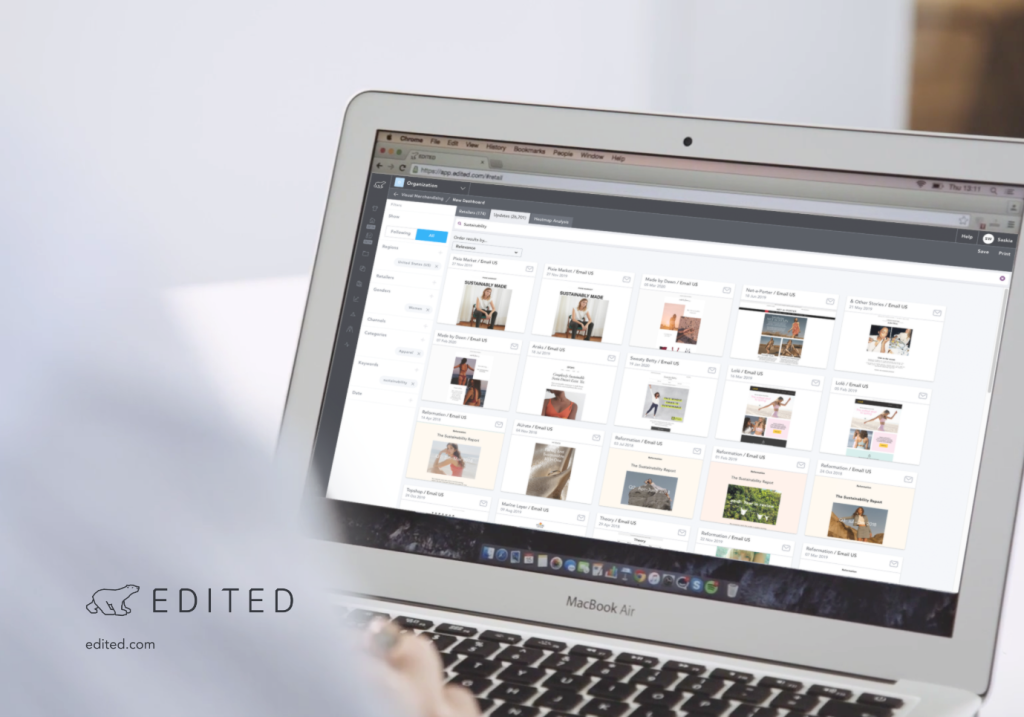

Thanks to the rise of e-commerce, the traditional practice of sending designers on a spy-shopping trip to several physical shops is no longer necessary. Having online retailers present their collections in a freely accessible, online public database (their web shop), enables you to do your market research remotely. If you need help, consultancies such as Edited track billions of stock keeping units daily and offer paid advice about trends in garment styles, colours, patterns and descriptions. See also the section on data, below.

Tips:

- Check WGSN’s trend forecasting and analytics reports for the fashion industry. The website offers a blog section highlighting the most important trends in apparel.

- Investigate the private brands by large European multi-brand platforms such as Zalando, Asos or Yoox to find brands that match your abilities.

- Follow Edited’s blog section for free information on the latest trends in the European apparel market. Trade media such as FashionUnited or Fibre2Fashion also offer free market intelligence and trend data.

- Read McKinsey’s report ‘The six vectors of success in online fashion’. It offers valuable data on trends in consumer spending on several apparel categories in European markets.

8. Let market data drive your sales strategy

The recipe for success in the apparel industry has always been having the right product in store at the right price, at the right moment. Traditionally, fashion professionals tried to achieve this by intuition, and sometimes pure speculation. Today, the industry trusts ever more in data: big amounts of it. Anything from inventory, material input, workflow and sales to online engagement via clicks, reviews and even likes and comments is being tracked and analysed. The aim is to uncover patterns and to optimise production and sales accordingly.

European buyers are primarily interested in big data and Artificial Intelligence because it offers an opportunity to better match supply and demand, to make more successful designs and to offer end customers a hyper-personalised shopping experience. Analysing big amounts of data points on sales and consumer preference makes it easier for designers and buyers to predict what will be the right style, silhouette, shape/fit, sizing, retail price and even the right way to describe and present the items online or instore and to whom.

The benefits of knowing your market

Manufacturers can use big data about market trends to determine which markets are growing or declining or getting more competitive, and which markets, segments and product categories fit best with their own strengths. It offers an opportunity to not only focus on what happens in your own business, with your own clients, but to also learn from what competitors are doing. Gaining such insights before talking to (potential) buyers can give you an upper hand in negotiations, and reduce the amount of issues during production and approval.

Free services such as Google trends or paid alternatives such as Semrush or KWFinder let you track and analyse Google search data for every search phrase imaginable, including apparel items. You can narrow your search by geographic location or time period.

Tips:

- Learn from this article on Medium how apparel companies use big data to better curate products for their end consumers, provide product recommendations, and improve targeting, resulting in a hyper-personalised shopping experience;

- Consider taking paid advice from consultancies such as Edited, who track billions of stock keeping units daily to analyse market trends;

- Read The State of Fashion 2024 report by consultancy firm McKinsey (PDF). It contains useful information about different growth strategies for online sales.

Figure 3: Market intelligence consultancies such as Edited.com analyse billions of stock keeping units daily to provide real time data on market trends. The results are accessible through an online dashboard.

Source: Edited.com

Use digitisation to become more sustainable

Sustainability and digitisation are interrelated subjects. They belong closely together because no supply chain can improve on sustainability without measuring impacts, which requires digitisation. Digitisation is used to measure, monitor and report on criteria in different stages of the value chain, such as soil depletion, use of herbicides and pesticides, animal wellbeing, forest maintenance, (loss of) biodiversity, water and energy use, carbon emissions, working hours, living wage, waste management and circularity.

Transparency

As Fashion Revolution writes in its Fashion Transparency Index, the first step towards sustainability is transparency. Without knowledge of your value chain and the impacts that occur, there is no possibility to improve. Also in this case, digitisation enables professionals to measure impacts on workers, communities and the environment, to analyse them, find patterns and to implement improvements. In the tips below, some technologies are mentioned that can trace raw materials back to their source.

The need for more transparency and sustainability in the apparel supply chain is obvious. The European Environment Agency (EEA) has reported that textiles are the fourth-largest cause of environmental pressure after food, housing and transport.A report by Mckinsey (2020) on consumer sentiment towards sustainability in fashion revealed that 57% of UK and German consumers have made significant changes to their lifestyles to reduce their environmental impact with 65%, making a commitment to purchase more durable fashion items.

The trend in the consumer market for sustainability is so strong, that the Austrian raw material manufacturer Lenzing Group has even decided to directly engage with end consumers via an e-shop. This web shop showcases over 200 products made of Tencel branded lyocell and modal fibre items online.

Tips:

- Take full supply chain responsibility. Use tracing technology such as tex.tracer, Haelixa or FibreTrace to physically and digitally trace raw materials back to their source.

- Use digital labelling solutions such as Avery Dennison to trace ready-made products during and after use. This makes it easier to collect, sort and eventually recycle apparel items.

- Consider registering your CSR performance on online platforms such as ISEAL, SIM Supply Chain, GSES, Ecovadis or Ecochain. This makes monitoring and reporting on sustainability easy and transparent.

Figure 4: 3D modelling has become so sophisticated that digital and physical samples are now difficult to distinguish

Source: CLO3D.com

3D sampling

These developments are likely to stay, even with the reopening of stores in Europe and the easing of travel restrictions. One technology that has risen in popularity is 3D sampling. Even before the pandemic, 83% of respondents in a 2019 report by McKinsey believed physical samples will be used less often than virtual samples by 2025. During the pandemic, ever more factories and brands started using Artificial Intelligence and 3D modelling technology, allowing suppliers to offer digital samples and speed up the approval process.

The use of 3D avatars connected to online databases with big data on body types of European end consumers allows manufacturers not only to speed up the approval process, but also to reduce wrong fits to a minimum. CLO offers a blog page on their website with user stories by companies such as Adidas, Dainese and Emilio Pucci. 3D solutions provider Browzwear offers user stories by companies such as Fruit of the Loom and Superdry.

3D avatars can be used not only in the approval process between manufacturers and brands, but also to set up virtual showrooms. When applied in (online) retail, it even allows end consumers to better choose the right apparel item (fit, shape, appearance), significantly reducing returns. A good example is H&M’s innovation lab in Berlin, Germany. It recently developed technology based on a 3D photogrammetry scanner. The virtual fitting solution will enable customers to try out clothing on their own individual avatars.

In 2021, H&M customers had the opportunity to virtually try on looks from the new collection from home and outside of store opening hours via digital fitting rooms in two stores in Berlin and one H&M store in Hamburg

Tips:

- Learn about the opportunities of using 3D sampling techniques by reading this article on Fibre2Fashion. Check 3D design software providers such as CLO, Lectra or Alvanon to learn about the latest techniques in 3D designing and prototyping.

- Watch this video on YouTube by Browzwear about the usefulness of 3D sampling.

- For more detailed information about the use of 3D technologies, consider following one of Alvanon’s webinars on the subject.

- Stay up to date on innovations and techniques by following Innovation in Textiles or Sourcing Journal.

- Recruit new digitally-native employees at your local university.

9. Maximise your flexibility using digital tools

A hyper-personalised product is the pinnacle of ‘the right product, for the right price, at the right time’. Unsold stock and the associated risk will be history if brands and retailers can provide end consumers with the apparel items that they exactly want, in every detail. Already European apparel buyers demand ever more flexible service, smaller order quantities and higher speed to market. The application of digital tools increasingly offers manufacturers the capability to offer maximum flexibility and eventually even tailor-made apparel.

Mass customisation

‘Mass customisation’ is not a new concept. Already in 1992 Joseph Pine called it ‘the new frontier in business competition’. Since then, its breakthrough has been predicted many times. Now finally thanks to digital technologies such as 3D sampling, online fitting rooms and fully automated machinery, more companies are experimenting with ‘mass customisation’. According to consultancy firm Deloitte customised apparel could account for as much as 30% of the clothing market by 2030.

There are many examples of fashion brands and retailers offering personalised clothing:

- Spreadshirt is an online platform that lets end consumers design their own T-shirts and hoodies;

- Nike was one of the first brands to popularise mass customisation. In 1999 it introduced NikeiD: a website that lets consumer design and order their own set of sneakers. The service is now available as ‘Nike by you’;

- Unmade offers software solutions for demand-driven fashion. The idea is to design and sell first, then produce, instead of design, produce and sell;

- Fashion brand Ralph Lauren offers custom, made-to-order polo shirts;

- Swedish fashion giant H&M has also started experimenting with made-to-order;

- Unspun offers customisable jeans to end consumers and advice to companies.

The benefit of mass customisation for factories and brands and retailers is the potentially significant reduction in waste and unsold stock.

Further Reading

- The CBI report ‘Which trends offer opportunities on the European apparel market’ offers a useful section on new technologies in apparel production.

- The CBI report ‘10 Tips on how to find European buyers’ can help you with finding interesting prospects and how to approach them.

- The CBI study ‘10 Tips on how to do business with European buyers’ provides tips on how to successfully approach a potential buyer and develop a long-lasting business relationship with them.

FT Journalistiek carried out this study in partnership with Frans Tilstra and Giovanni Beatrice on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research