7 tips to go green in the apparel sector

Going green means minimising negative impacts on people, animals and the environment. The apparel industry is one of the most environmentally harmful industries in the world, and its impact is clearly visible in polluted production areas. Meanwhile, end markets struggle with large amounts of apparel waste. Manufacturers have an important responsibility to produce items in an environmentally friendly manner and to source materials from suppliers that do not cause pollution. This report explains how you as an apparel manufacturer can ‘go green’.

Contents of this page

- Familiarise yourself with the many aspects of environmental responsibility

- Make sure to comply with legal and non-legal sustainability requirements

- Identify the biggest opportunities for becoming more environmentally friendly in apparel

- Measure and reduce your carbon footprint

- Apply green innovation to your production facility

- Make sure your investment in sustainability pays off

- Publish and share your own green code of conduct

1. Familiarise yourself with the many aspects of environmental responsibility

It is estimated that apparel production causes 10% of all global greenhouse gas emissions. It is also the second-largest consumer of water while causing 20% of water pollution worldwide. Less than 1% of post-consumer waste is recycled. The apparel industry has long been based on the linear ‘take-make-waste’ model. This means that non-renewable resources and cheap labour are used to produce apparel items that are burned or landfilled after use. Much of the environmental impact occurs during production, the model’s ‘make’ phase.

In recent years, however, end consumers, NGOs, brands and regulators have been pushing for more sustainability in the industry. Brands have responded to conscious consumerism by using eco-friendly materials and sustainable production practices. This includes the use of organic cotton and recycled materials, such as recycled polyester (rPET). Brands are also focused on implementing more efficient manufacturing processes by reducing energy consumption and minimising waste.

The European Union is currently a major force behind the transition to a sustainable apparel industry. By implementing a ‘Green Deal’, it wants to “move to a clean, circular economy and stop climate change, revert biodiversity loss and cut pollution”. Several new legal measures are being introduced, including new laws on due diligence regarding human rights and environmental protection, a new ‘carbon border adjustment mechanism’ and extended producer responsibility (EPR).

All these measures aim to move the industry away from the old take-make-waste model. The transition to a sustainable apparel industry in Western markets will influence every step in the value chain, from raw material production to end of use. Suppliers need to be aware of their place in the (circular) value chain, know the responsibilities that come with that position and use this knowledge to set priorities.

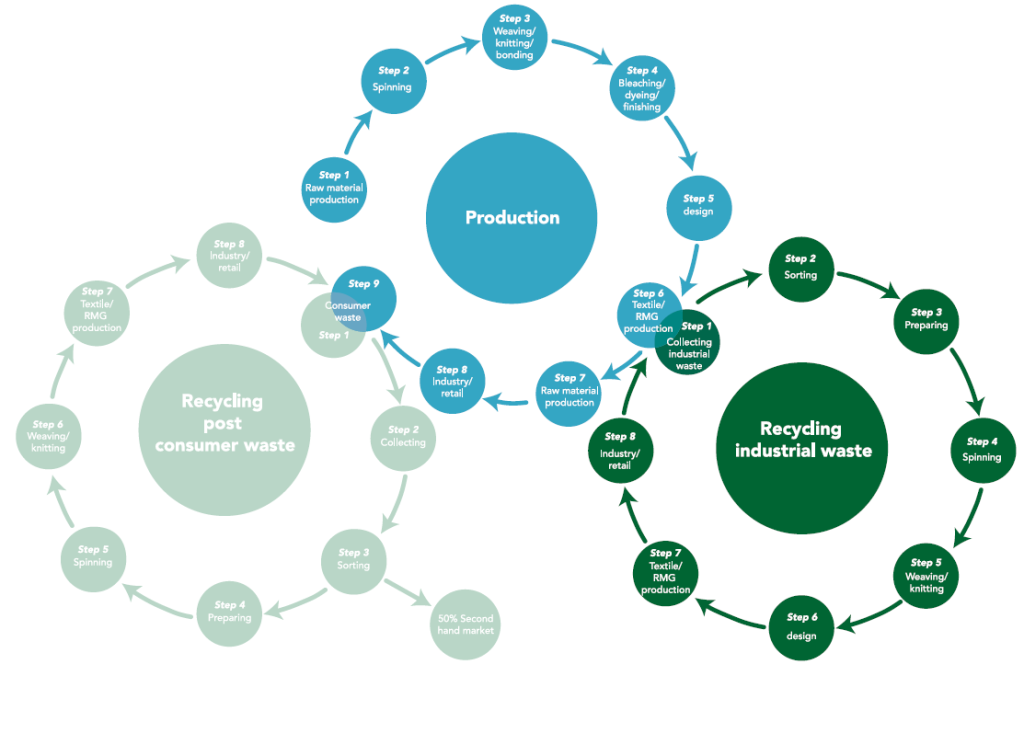

Figure 1: Overview of the circular apparel value chain

Source: Forward in Fashion

Recycling industrial textile waste happens during the production of ready-made apparel items. Cuttings from the factory floor are turned into new fibres, yarns and fabrics that can be used in the garment-making process. The recycling of apparel after use by end consumers follows largely the same process, although roughly 50% of all post-consumer waste is sold in the second-hand market after collection.

Reduce-replace-eliminate-offset

If you are an apparel manufacturer, ‘going green’ means minimising the environmental impact of all production processes that take place in your factory. The first step you can take to minimise your impact is to reduce the use of harmful inputs. This applies to all the inputs you use in the production process (including the inputs you source from other suppliers):

- materials used in the production of ready-made garments: fabrics, accessories;

- energy used to maintain buildings and to operate all machinery used in the production process;

- water used in wet processing and to maintain buildings and surroundings;

- chemicals used in the production process (primarily wet processing);

- packaging materials and logistics;

- materials and inputs used to build and maintain your production facilities.

Harmful or unsustainable inputs can be reduced by:

- using more efficient machinery or production processes;

- recycling inputs;

- replacing inputs with more sustainable alternatives (including recycled inputs);

- eliminating inputs from the production process.

Impacts that cannot reasonably be reduced any further may be offset (compensated). For instance, it is common practice for large Western companies to offset CO2 emissions (see also below) on the voluntary carbon market.

Table 1: Opportunities for reducing environmental impact in each step of the value chain

| Value chain step | Opportunities |

| Raw material production |

|

| Spinning, weaving or knitting |

|

| Dying, bleaching and finishing |

|

| Design |

|

| Ready-made garment production |

|

| Packing and transport |

|

| Data collection |

|

Tips:

- Many brands and retailers are working with multi-stakeholder organisations, such as the Sustainable Apparel Coalition and the Global Fashion Agenda, to promote sustainability across the entire apparel value chain. These platforms are open to manufacturers too. Connecting with industry initiatives keeps you updated on new developments and gives you access to sources of new information and useful tools.

- Check the EU’s website for the European Green Deal (which includes a timeline) to keep yourself updated on coming policy changes.

2. Make sure to comply with legal and non-legal sustainability requirements

If you want to ‘go green’, your priority should be to comply with local labour and environmental laws, for instance concerning the use of water and energy and the treatment of solid and liquid waste. If you plan on exporting your products, you should also investigate the laws and regulations of your export market to make sure you comply with those as well. But buyers in your export market may also require you to comply with non-legal, but non-negotiable requirements. So going green means doing more than what is legally required to make your production process sustainable.

Legal requirements

One of the most important legal requirements for exporting to the European Union is the REACH Regulation. This restricts the use of chemicals in apparel and trims, including certain azo dyes, flame retardants, waterproofing and stain-repelling chemicals and nickel. This legal requirement is intended to guarantee consumer safety. It is not intended to promote environmentally friendly production.

Future requirements

The EU is implementing several new directives aimed at making apparel production and imports more sustainable. You should expect to see the effects of these new laws in the coming years, as European buyers will want to share the compliance responsibility with you, their supplier. New regulations include the Corporate Sustainability Reporting Directive (CSRD), which requires all large European companies from 2023 onward to disclose how they manage social and environmental challenges. Under a new anti-deforestation law, companies that sell leather (not leather products) to the EU will need to have a 100% transparent and traceable supply chain.

As part of the transition to a circular economy, the EU will introduce new legal measures to increase circularity in the textile industry, including new directives concerning the durability of textile products and the ‘right to repair’. The EU is also considering the introduction of an EU-wide EPR for apparel (extended producer responsibility). This would make companies responsible for the way their products are disposed of, recycled or repaired. Some countries, including the Netherlands, have already implemented national EPR schemes.

Buyer-specific requirements

Buyers may require social and environmental audits of raw materials production or production facilities. These can be conducted by the buyer itself or by an independent third party. They may be announced or unannounced. Factories and mills that do not provide full access will usually be blacklisted and will no longer receive orders. On top of this, many buyers have created their own restricted substances lists (RSLs). These are based on industry and regulatory standards (often ZDHC) that suppliers of both materials and garments must follow.

Table 2: Key certifications for sustainable materials in the European apparel market

| Name | Logo | Description | Further information |

| OEKO-TEX® 100 |

| Tests fabrics and accessories for substances considered harmful to human health. Most European brands require that products carry the OEKO-TEX quality mark. | Learn more about the STANDARD 100 by OEKO-TEX® application process here |

| OEKO-TEX® STeP |

| Social and environmental certification system for brands, retailers and manufacturers in the textile and leather industries. Certification is possible for production facilities at all processing stages. | Learn more about the OEKO-TEX® STeP application process here |

| EU Ecolabel |

| The EU Ecolabel is a voluntary label for products and services with a reduced environmental impact. It is awarded only to products with the lowest environmental impact in a particular product category. | Learn more about the application process for the EU Ecolabel here |

| BCI | The Better Cotton Initiative (BCI) is a non-profit, multi-stakeholder governance group that promotes better standards in cotton farming and practices across 21 countries. | Learn more about the BCI membership process here | |

| GOTS |

| The Global Organic Textile Standard (GOTS) is the leading standard for organic textiles. It applies to the harvesting of raw materials, environmentally and socially responsible manufacturing and labelling. | GOTS provides a list of organisations that can perform an audit |

| C2C |

| Cradle to Cradle Certified® is a third-party certification programme and a standard for materials and products considered to be safe, circular and responsibly made. Products are assessed according to five categories of sustainability performance, including material health, product circularity, clean air and climate protection, water and soil stewardship, and social fairness. | Learn more about the C2C® certification process here |

| Bluesign® |

| The use of Bluesign®-approved chemical products and materials increases the safety of products and minimises risks for companies throughout the value chain. Bluesign®-approved textiles are sustainably produced and assessed according to the Bluesign® criteria. | Learn more about the Bluesign® assessment process here |

| ZDHC | A multi-stakeholder programme that leads the apparel industry in eliminating harmful chemicals from supply chains. | ZDHC provides a guide that outlines the requirements for indicating ZDHC MRSL conformance | |

| Sedex | Online platform that helps companies manage and improve working conditions and environmental protection in global supply chains, from raw material production to garment manufacturing. | Learn more about the Sedex certification process here | |

| Fairtrade |

| Fairtrade is a non-profit organisation that helps smallholder farmers and workers in developing countries. It is a movement to reduce poverty and promote fair and equal opportunities. It is also a quality mark for products for which a fair price has been paid. | Learn more about the Fairtrade certification process here |

Tip:

- To learn more about buyer requirements, including environmental standards and certifications, read the CBI studies What are the requirements for apparel to enter the European market? and The European apparel market and sustainable fashion.

Figure 2: OEKO-TEX, BCI and GOTS are among the most popular European sustainability standards

Source: FT Journalistiek

3. Identify the biggest opportunities for becoming more environmentally friendly in apparel

The transition to a sustainable apparel industry will have enormous social and environmental benefits for the global community. It is estimated that a sustainable, circular economy would help save more than €400 billion every year. The apparel industry going green will also stimulate competition, innovation, economic growth and job creation. In the years ahead, companies making the shift to sustainable apparel production will gain a competitive advantage.

Table 3: Motivations for apparel manufacturers to ‘go green’

| Intrinsic values | Protecting the environment needs to be a core value of every organisation, as it is this generation’s responsibility to secure a safe future for the next. |

| Consumer demand | End consumers are increasingly concerned about the environmental impact of the products they buy, including apparel. Manufacturers that demonstrate a commitment to sustainability are more likely to attract and retain environmentally conscious consumers. |

| Buyer requirements | As more and more buyers are demanding data on the environmental impact of apparel production, the true value of products will not only be determined by production costs, but also by sustainability. |

| Regulatory requirements | Governments are introducing more regulations to reduce the environmental impact of manufacturing activities. Apparel manufacturers that fail to comply with these regulations risk facing penalties and damage to their reputation. |

| Resource efficiency | Sustainable manufacturing practices can help apparel manufacturers become more resource-efficient. This reduces production costs, increases financial stability and profitability, and ensures long-term sustainability. |

| Brand reputation | Manufacturers that demonstrate a commitment to environmental sustainability can improve their brand reputation and increase their competitive advantage. |

| Supply chain management | Focusing on sustainability can help apparel manufacturers improve supply chain management, by ensuring that suppliers and partners meet environmental standards and by promoting transparency throughout the supply chain. |

Sustainable materials

Apparel factories will need to reduce their environmental impact by using materials that are more environmentally friendly, such as organic cotton, flocus and biodegradable polyester. This will not only help meet the growing market demand for sustainable fabrics but also reduce local environmental impact.

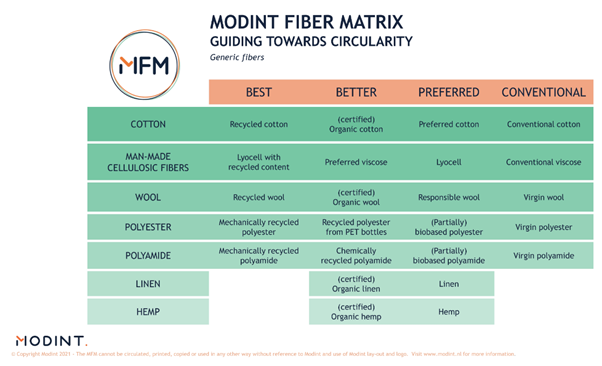

Figure 3: Modint’s Fiber Matrix shows the relative sustainability of common textile materials

Source: Modint Fiber Matrix. © Modint

Implementing environmentally friendly manufacturing practices

Green manufacturing practices help apparel manufacturers reduce both their environmental impact and production costs. The most important measures include:

- reducing the use of fossil fuels or ‘grey’ electricity by investing in energy-efficient machinery;

- replacing environmentally harmful energy sources with renewable sources such as solar, wind and biogas;

- reducing the use of fresh water by investing in more efficient wet processes and water treatment and recycling techniques;

- reducing the use of chemicals by investing in more efficient wet processing;

- replacing harmful chemicals with eco-friendly alternatives.

Investing in more efficient machinery and generating your own energy and water supply reduces your environmental impact, but it will also help you save costs and limit your dependence on other energy sources. While the installation and maintenance of solar panels or a water treatment plant does require an initial investment, a factory that can produce apparel without any dependence on third parties will ultimately have very low risk and a strong competitive advantage.

Circularity

Implementing circular-economy practices, such as recycling and repurposing materials, can help apparel companies reduce waste and conserve resources. This includes post-consumer waste. The European Green Deal is making it mandatory for the industry to reuse and recycle apparel waste. Collecting waste and helping buyers reuse and recycle industrial and post-consumer waste will enable them to comply with EU legislation. At the same time, it will enable manufacturers to explore new markets.

Increasing production quality standards

If you can, encourage buyers to purchase products that are manufactured according to higher quality standards. Feel free to advise buyers on styles and materials that will extend the lifespan of their products. This benefits sustainability, but you can also point out that there are commercial reasons for them to do so. Higher-quality products allow buyers to target the second-hand market, which is currently the fastest growing market in the apparel industry.

Best practices

In 2021, the China-based company Esquel Group announced its commitment to becoming carbon neutral by 2050. Esquel installed solar panels at its facilities to generate green energy, as well as its own wastewater treatment plant. This facility has the capacity to recirculate 3,000 tonnes of purified water back into the production process daily, filtering out harmful chemicals. The company is Zero Discharge of Hazardous Chemicals (ZDHC) compliant.

In India, Arvind is working on reducing the environmental impact of its 4 key inputs: fibres, water, energy and chemicals. The company analysed its impact on climate change and adopted an action plan to reduce its climate risk. It will integrate solar and biomass power into its energy mix, eliminate its use of fresh water, limit water discharge and maximise water recycling, directly source BCI cotton and organic cotton from regenerative farmers and introduce energy-efficient machinery.

4. Measure and reduce your carbon footprint

The apparel industry is estimated to be responsible for over 8% of global carbon emissions, making it a significant contributor to climate change. Still, the exact amount of GHG emissions per kilogram of product can vary widely for apparel items. This depends on factors such as the materials used, the manufacturing process and the production location. It is estimated that on average, the production of 1 kilogram of cotton results in up to 23 kilograms of CO2 emissions. Synthetic fibres like polyester result in up to 3 times more emissions.

Additionally, the transportation of goods and the use of energy-intensive processes such as dyeing and finishing can also contribute significantly to the apparel sector’s total emissions.

What is measured

Measuring the carbon footprint of an apparel item typically involves analysing the product’s entire lifecycle, from the sourcing of raw materials to production, distribution, use and end-of-life disposal.

- Material sourcing: the emissions associated with the sourcing of the raw materials, such as emissions from growing cotton or raising animals for wool.

- Production: the emissions associated with the production process, such as the energy used to run factories and the emissions from the transportation of raw materials and finished products.

- Distribution: the emissions associated with the transportation of the product from the factory to the retail store.

- Use: the emissions associated with the use of the product, such as the energy used to wash and dry clothes.

- End-of-life disposal: the emissions associated with the disposal of the product, such as emissions from landfilling or incineration.

Tips:

- To learn more about opportunities for going green, sustainable materials and industry standards, read the CBI studies The European apparel market and sustainable fashion and The sustainable transition in apparel and home textiles, or our study on sustainable cotton, Exporting sustainable cotton to Europe.

- See Solidaridad’s Wet Processing Guidebook for an overview of industry initiatives, tools, certificates, guidelines and strategies for reducing social and environmental impacts during the wet-processing stage of material production.

- Use the Material District or Springwise online databases to stay up to date on innovations in sustainable production methods and apparel production materials.

- Subscribe to online publications such as Sourcing Journal, Just Style and the Business of Fashion for the latest news about sustainable materials.

Calculating the CO2 footprint of your product

To calculate the carbon footprint of a product, the emissions are usually measured in units of carbon dioxide equivalent (CO2e), after which the total emissions are divided by the number of products. The calculation itself is a complex process. There are several organisations, industry platforms and standards that have set benchmarks for certain materials and products. Others can help you calculate the carbon footprint of a specific product and identify areas for improvement:

- The Sustainable Apparel Coalition’s (SAC) Higg Index. This is a set of tools for the standardised measurement of value chain sustainability. Brands, retailers, manufacturers, governments, NGOs and consumers can use the Higg Index to learn more about sustainability strategies for reducing their water use and carbon emissions, and to improve their labour conditions.

- OEKO-TEX offers an impact calculator to track your carbon and water footprint.

- Consultancies such as The Carbon Trust and the Climate Neutral Group can calculate the carbon footprint of your organisation or individual products. They can also advise you on how to reduce or offset your impact.

Tips:

- Many Western brands are committed to achieving climate neutrality. Have a look at the Charter for Climate Action, a pledge by over 40 major fashion brands to achieve net zero emissions by 2050.

- Investigate different methods of calculating your carbon footprint and choose the most suitable standard for your situation. Introduce the tool to your stakeholders and make sure that each stakeholder measures their individual carbon footprint. Share and report results and discuss potential improvements with your stakeholders, including buyers.

- To learn more about where most GHG emissions occur in the apparel value chain and how they can be measured and reduced, read this paper by Elsa Dominish for ILO.

5. Apply green innovation to your production facility

Being a ‘green’ manufacturer is about more than just the production process. It starts with the building and maintenance of your factory. Try to use the most environmentally friendly resources for the construction and operation of your facilities.

When constructing or making changes to your factory, take the following into account:

- Use recycled or environmentally friendly construction materials. Ask your building company for options.

- Surround your factory with trees. These will provide shade and lower the indoor temperature. You can also consider installing a ‘green roof’ to save energy and create a pleasant environment for your workers.

- Install solar panels, wind turbines, bio energy facilities, infrared heating, heat pumps and batteries to store energy.

- Install a water treatment and recycling facility.

- Reduce electricity usage (by installing LED lighting) and train staff on how to minimise electricity usage.

Tips:

- Use industry standards such as BREEAM, LEED, Energy Star or ISO 14001 to certify your facilities and operations.

- An apparel factory should be environmentally friendly, but it should also be a pleasant working environment, so provide natural daylight and ventilation. Natural colours and surroundings are also important. A pleasant working environment ensures a happy, loyal and productive workforce.

6. Make sure your investment in sustainability pays off

Having an environmentally friendly manufacturing process will increase buyer interest. There is more and more evidence to suggest that companies with strong sustainability practices can outperform their peers in the long term, and that they provide attractive investment opportunities. However, before you spend money on costly sustainable production techniques, you need to make an informed decision.

Always make a realistic calculation of your return on investment (ROI). Balance all investment costs (purchase and write-down of machinery, training of employees) against the expected benefits (reduced inputs and associated costs, higher price points for products and higher appreciation in the market).

Table 4: The risks of going green

| Uncertainty in measurement | Sustainability metrics can be difficult to standardise and quantify, making it challenging for investors to accurately assess the sustainability performance of a company or sector. |

| Reputational risk | Companies that are not transparent about their sustainability practices, exaggerate their performance (‘green washing’) or have a history of environmental or social controversies face reputational risk. This can negatively impact their financial performance. |

| Market risk | Sustainability priorities are affected by market dynamics, just like any other aspect of the market. Buyers may value different aspects of sustainable production over time. In other words: there are trends in sustainability requirements. What buyers look for when it comes to sustainable production can also differ between product categories, market segments and of course between individual buyers. Make sure that your investments in sustainable production match your target market by learning more about your buyers’ requirements. |

Tips:

- Balance your CSR investment strategy with your profitability.

- Only invest in green innovations if success is guaranteed (proof of concept). New sustainable technologies are introduced constantly, but if you decide to invest in a technology it should have proven itself over a longer period of time. Ask suppliers for their track record (including after-sales service!) and get references, for instance by asking other factories about their experiences with certain technologies.

- Stay up to date on buyers’ ambitions and include these in the development of your CSR investment strategy.

- Use your mission to ‘go green’ as a tool to attract new business.

- Look at the front runners in the industry and learn from their successes.

7. Publish and share your own green code of conduct

‘Going green’ is not just about meeting buyers’ requirements, but also about acting on your own principles. So you should develop your own corporate social responsibility (CSR) policy or code of conduct that goes beyond laws and regulations. In these documents, companies share goals that are of particular interest to them. Examples include saving water or energy, reducing carbon emissions, reducing pollution, recycling (production) waste and sourcing environmentally friendly materials, including new, innovative materials.

- In your code of conduct, include a commitment to reducing your organisation’s environmental impact and promoting sustainable practices.

- Establish goals and guidelines for reducing energy consumption, waste and emissions, both in the office and on the work floor.

- Encourage employees to adopt environmentally friendly habits, such as recycling and using public transportation.

- Describe the standards and requirements suppliers must meet when it comes to health and safety, labour rights and the sustainable production of fabrics and other materials.

- Educate employees about the importance of protecting the environment and the specific actions they can take to make a positive impact.

- Regularly review and update your code of conduct to ensure that it aligns with current environmental best practices.

- Show your commitment to your local community by supporting environmental causes and organisations.

- Implement due diligence processes to assess and monitor supplier compliance with your company’s standards and requirements, including through regular audits and assessments.

- Publish your code of conduct online and make sure your suppliers, employees, buyers and other stakeholders know where to find it.

Further Reading

The CBI report ‘10 Tips for Finding European Buyers’ can help you find and approach interesting prospects.

The CBI study ‘10 Tips for Doing Business with European Buyers’ provides tips on how to successfully approach potential buyers and develop long-lasting business relationships with them.

This study was carried out on behalf of CBI by Frans Tilstra and Giovanni Beatrice for FT Journalistiek.

Please review our market information disclaimer.

Search

Enter search terms to find market research