10 tips to measure and reduce your carbon footprint

The global apparel industry is a big contributor to climate change. Of all the greenhouse gases in the atmosphere, carbon dioxide (CO2) is the most abundant. This is well understood by the EU, national governments and many European apparel brands, who have made fighting climate change a top priority. This report provides tips for measuring and reducing your carbon footprint, and for sharing monitoring data about your progress with European buyers.

Contents of this page

- Understand the definition and scope of CO2 emissions

- Understand the importance of measuring and reducing your CO2 emissions

- Consider your entire value chain when reducing CO2 emissions

- Make sure you comply with all legal requirements concerning CO2

- Familiarise yourself with non-legal buyer requirements

- Measure your CO2 footprint

- Reduce your CO2 footprint

- Share data with both buyers and internal stakeholders

- Learn from best practices

- Stay updated on future requirements and solutions

Figure 1: Carbon dioxide is the most abundant greenhouse gas

Source: Callum Shaw on Unsplash

1. Understand the definition and scope of CO2 emissions

When talking about climate change or global warming, experts use different terms to discuss its root causes. The most abundant greenhouse gas in our atmosphere is carbon dioxide (CO2), which makes up around 76% of all greenhouse gases (GHGs). Other greenhouse gases include methane (from waste and agriculture) and nitrous oxide (from industrial activities). All these gases trap heat in the atmosphere and contribute to global warming.

Calculating your carbon footprint – how much carbon dioxide you produce – is a market requirement. It is also a necessity created by global warming. Reducing the world’s carbon footprint is crucial to secure a healthy environment for future generations. To open doors to European apparel buyers, you need to be able to deliver proof you have significantly reduced the carbon footprint of your factory, suppliers, transportation and every other part of your production chain. This is called the ‘scope’ of your carbon footprint.

Scope 1, 2 and 3

When developing a CO2 emission reduction strategy, it is important to understand all the actors and processes that contribute to your carbon footprint. ‘Scope 1’, ‘2’ and ‘3’ indicate the different kinds of CO2 emissions a company creates in its operations and wider value chain. The term was introduced by the Greenhouse Gas Protocol (2001) and has since been adopted by other frameworks and legislation intended to reduce CO2 emissions, including the UN Paris Agreement (2016) and the EU’s Corporate Sustainability Reporting Directive (CSRD, 2022) and Corporate Sustainability Due Diligence Directive (CSDDD, 2024).

Table 1 describes what is meant by Scope 1, 2 and 3 emissions. Typically, Scope 3 emissions make up most of companies’ carbon footprints. They cover emissions from the entire value chain beyond direct operations, including raw material production (e.g. polyester production) as well as emissions caused by waste disposal. From the viewpoint of a European apparel buyer, your CO2 emissions are their Scope 3 emissions. Larger EU companies need to report on these, so you need to be able to provide them with this data.

Table 1: The different scopes of CO2 emissions

Scope 1 (Direct Emissions) | These are the direct emissions from sources that companies own or control. This includes emissions from company-owned assets, such as:

Essentially, Scope 1 covers emissions that come directly from your facilities and all activities under a company’s control. |

| Scope 2 (Indirect Energy Emissions) | Scope 2 refers to indirect emissions from the consumption of purchased energy, such as electricity, steam, heating and cooling. These emissions are created off-site, where the energy is generated, but they are accounted for by the company using the energy. They typically include:

While these emissions are not directly under a company’s control, they result from the energy the company uses. |

Scope 3 (Other Indirect Emissions) | Scope 3 covers all other indirect emissions that happen across a company’s value chain, both up and downstream. Companies do not produce these emissions directly but they are a consequence of their activities, including:

|

Source: FT Journalistiek

Tips:

- Read this article by the World Resources Institute for an overview of measures to reduce CO2 emissions across the apparel value chain.

- Focus on reducing CO2 emissions first, as it is usually the largest contributor to your factory’s carbon footprint.

- Try to work with your suppliers to discuss strategies for reducing emissions throughout the supply chain.

2. Understand the importance of measuring and reducing your CO2 emissions

Over the last three years, record-breaking heatwaves have swept across the world leading to wildfires, droughts and floodings. Climate change affects poor countries the most. Less predictable rain patterns, droughts and water scarcity have caused hunger in parts of Africa and severely affected agricultural production all over the world, including in many cotton-growing countries. Reducing your carbon footprint is better for the environment, it saves costs and gives you a competitive advantage.

CO2 emissions are the primary cause of global warming. CO2 is a greenhouse gas, trapping heat in the Earth’s atmosphere. Moreover, approximately 30% of emitted CO2 is absorbed by oceans, where it reacts with seawater to form carbonic acid, leading to ocean acidification.

As global temperatures rise, polar ice caps and glaciers melt, contributing to rising sea levels. Thermal expansion (where water expands as it warms) is another key factor driving sea level rise. This can result in coastal erosion, increased flooding and displacement of communities. Higher CO2 levels can trigger feedback loops that further increase climate change.

Besides reducing your environmental impact, key benefits of adopting a climate neutral strategy include:

- Better company reputation. Buyers prefer manufacturers that demonstrate environmental responsibility and have the right certifications.

- Cost savings. Energy-efficient practices and sustainable materials can reduce energy costs and waste management expenses.

- Regulatory compliance. As the EU and local governments implement stricter environmental regulations, adopting a carbon-neutral strategy will help you to stay ahead of compliance requirements. Companies may also benefit from government incentives for reducing carbon emissions.

- Attracting talent. Promoting a sustainability-driven culture can encourage innovation and creativity amongst employees.

- Transparency. Demonstrating accountability through carbon reduction can build trust with buyers and governments.

Tip:

- Check the UN’s website for clear background information on the causes and effects of climate change and the role that CO2 emissions play in this process.

3. Consider your entire value chain when reducing CO2 emissions

Reducing CO2 emissions goes beyond your own operations: it involves your suppliers too. Most of the environmental impact comes from the production of raw materials, especially synthetic fibres like polyester, as well as fabric dyeing and garment manufacturing. These processes are highly energy-intensive, particularly if they are reliant on fossil fuels. It is estimated that more than 70% of the apparel industry’s emissions come from these production stages.

In addition, the global nature of apparel production causes significant transportation emissions. Apparel items are produced in countries like China, Bangladesh and Vietnam, and are then shipped around the world. Shipping and air freight contribute up to 15% to the overall carbon footprint of an apparel item according to McKinsey’s Fashion on Climate report.

The waste stage

Another reason the apparel industry contributes so much to climate change is fast fashion’s rapid production cycle, which encourages over-consumption and short product life spans. Each year, around 92 million tonnes of textile waste are generated globally. Much of this ends up in landfills or is burned, leading to CO2 emissions. Only 1% of discarded apparel items are reused or recycled into new garments.

Table 2: CO2 emissions caused during the most impactful stages in the life cycle of an apparel item

| Raw Material Production | Producing natural fibres is water and energy-intensive. Cotton farming involves significant fossil fuel use for fertilisers, pesticides, irrigation and mechanisation, leading to high CO2 emissions. Wool also contributes to GHG emissions because sheep emit methane. Synthetic fibres are derived from petrochemicals (oil and gas), and their production involves significant energy use for extraction, refinement and polymerisation processes. Polyester production generates two to three times more CO2 than cotton. |

Dyeing | The textile dyeing process is one of the most polluting stages. It requires large amounts of energy for heating water and applying chemicals. Many dyeing facilities rely on coal and gas for heat, contributing to high CO2 emissions. Additionally, wastewater from dyeing processes often contains harmful chemicals, leading to environmental degradation. |

| Washing and Pre-treatment | Washing and bleaching fabrics before production requires energy, typically using fossil-fuel-powered boilers to generate hot water and steam. Pre-treatment processes (e.g. de-sizing, scouring) also rely on chemicals that are often energy-intensive to produce. |

| Finishing Processes | Textile finishing processes, such as coating or applying chemical treatments for water or wrinkle resistance, require significant heat and energy. These processes often involve thermal drying or curing at high temperatures, leading to further emissions. |

| Manufacturing | Cutting, sewing and assembling garments all consume energy, mainly electricity. In developing countries, much of this electricity is generated by coal or gas, leading to CO2 emissions. However, emissions from manufacturing tend to be lower compared to fibre production and dyeing. |

Transport | Once manufactured, apparel is transported from production facilities to retail stores or consumers. Transport by sea generates fewer emissions, but air freight is much more carbon-intensive. On average, air transport creates 50 times more CO2 emissions than sea transport per tonne of goods. |

Waste Disposal | Post-production waste, including fabric offcuts and rejected items, often ends up in landfills or waste centres where they decompose or are burned, releasing CO2 and other greenhouse gases. Synthetic fibres can also take hundreds of years to decompose, releasing microplastics into the environment. |

Source: FT Journalistiek

Tips:

- Read this 2024 article by McKinsey on the effects of the ever stricter laws and pressures on the global apparel value chain.

- Read this report published by UNEP (2023) on sustainability and circularity in the global apparel value chain for background information on climate impacts and recommendations to achieve a sustainable value chain.

4. Make sure you comply with all legal requirements concerning CO2

European buyers will ask you to measure and reduce your carbon footprint and report on the results because laws require them to do so on both the EU and Member State level. Several production countries in Asia and Africa have also adopted policies and regulations to reduce CO2 emissions. These include apparel-producing countries like China, India, Indonesia, Morocco, Ethiopia and Rwanda. Make sure you comply with all national and international laws and regulations when you export apparel.

In Europe, companies that import apparel must adhere to the following laws and regulations.

- The EU Green Deal: This initiative aims to achieve climate neutrality and foster a circular economy. It encompasses various policies and actions to promote sustainable practices across sectors.

- The Corporate Sustainability Reporting Directive (CSRD, 2023): The CSRD imposes strict reporting requirements on companies regarding their environmental, social and governance (ESG) performance. This directive aims to enhance transparency and accountability in corporate sustainability efforts.

- The Corporate Sustainability Due Diligence Directive (CSDDD, 2024): This directive requires companies to conduct thorough assessments of their supply chains to identify and mitigate adverse environmental effects. It targets around 17,000 larger European companies and mandates specific steps to align business practices with global climate goals.

- Extended Producer Responsibility (EPR, 2023): Recycling is becoming more and more important for European buyers because the EU is introducing new legal measures including a ‘right to repair’ and an EU-wide EPR scheme. The scheme makes companies responsible for how their products are disposed of, recycled or repaired. Producers are required to develop systems for the collection, recycling and disposal of garments. The Netherlands, France and Sweden have already introduced national EPRs.

- Green Claims Directive: This directive requires apparel brands to substantiate their environmental claims with verified data. Companies must back up statements like ‘eco-friendly’, ‘sustainable’ and ‘carbon neutral’ with a Product Environmental Footprint (PEF), ensuring transparency and trust in sustainable product labels.

- Product Environmental Footprint (2024): This legislation aims to establish a standardised methodology for assessing and labelling the environmental impact of products. It will provide consumers with reliable information to make sustainable purchasing decisions.

- Ecodesign for Sustainable Products Regulation (2023): This regulation establishes minimum sustainability criteria for various product groups, including textiles and apparel. It mandates that companies have to provide information about the carbon footprint and other sustainability aspects of their products through a Digital Product Passport.

- The EU’s upcoming carbon border adjustment mechanism (CBAM) could impose taxes on imports based on their carbon footprint. Factories with lower carbon footprints will have a competitive advantage as they will be less affected by the tax. The mechanism does not apply to textile products or apparel yet, but it could in the future.

National laws

In addition to EU laws and regulations, several EU Member States have introduced national laws to reduce CO2 emissions. These include France (Energy Transition for Green Growth Act), Germany (Supply Chain Act), Denmark (Danish Climate Act), the Netherlands (Dutch Climate Agreement) and Sweden (tax system promoting sustainability).

Tips:

- Read the CBI study on workwear. This product category is considered leading in climate action thanks to its business model. Workwear companies usually sign long-running contracts with their buyers, making it easier to predict future orders. For instance, Dutch workwear brand Schijvens provides accurate CO2 reports for its products.

- On the other end of the fashion spectrum are fast-fashion companies, such as Primark and H&M. Read their CO2 reduction strategies for inspiration. These companies focus heavily on making single items more sustainable, as it is not their business model to reduce the number of items they sell.

- For an overview of European laws and regulations on CO2 emissions, check the EU’s ‘Fit for 55’ package. This is a proposal to update and align all new and existing regulations with the EU’s goal to reduce CO2 emissions by at least 55% by 2030.

5. Familiarise yourself with non-legal buyer requirements

In addition to legal requirements, many European apparel brands have set voluntary standards and ambitions for themselves to reduce CO2 emissions in their operations and supply chains. These are often based on industry initiatives and collaborative pledges to fight climate change. Buyers may require manufacturers to follow their standards, or to work in line with industry initiatives.

Voluntary standards

Many buyers follow voluntary standards, such as the Carbon Trust Standard or ISO 14064, which outline best practices for measuring and reducing GHG emissions. Buyers may require suppliers to use specific tools to calculate and report emissions, such as the GHG Protocol or specific carbon footprint calculators.

Industry initiatives

Buyer requirements can also be based on apparel industry initiatives. These include the following:

The Fashion Pact

Launched in 2019, The Fashion Pact is an initiative signed by over 200 global companies in the fashion and textile industry, including Kering, Adidas and H&M. The pact focuses on three key areas: climate, biodiversity and oceans. There are also specific commitments to achieve net-zero emissions by 2050. Members aim to implement science-based targets to reduce their carbon footprints and foster collaboration throughout the supply chain.

Textile Exchange

Textile Exchange is a global non-profit organisation that promotes the adoption of sustainable practices in the apparel industry. It encourages brands to set ambitious sustainability goals through various initiatives, including the Climate+ Programme. This programme helps companies develop and implement climate action strategies to reduce their emissions.

Cascale

Cascale (formerly known as the Sustainable Apparel Coalition) is an industry-wide collaboration focused on improving the sustainability of apparel, footwear and textile products. It developed the Higg Index, a set of tools that enable apparel brands to measure their environmental and social impact. Members are encouraged to report their progress publicly and set targets for emissions reductions.

UN Fashion Industry Charter for Climate Action

This charter, initiated by the United Nations Framework Convention on Climate Change (UNFCCC), aims to unite the fashion industry around the common goal of achieving net-zero emissions by 2050. It provides a framework for brands to commit to science-based targets and implement strategies to lower their carbon emissions throughout the supply chain. Signatories include H&M, Inditex, Hugo Boss, OTTO group and Puma.

Circular Fashion Initiatives

Many brands are adopting circular fashion models that emphasise sustainability and waste reduction. Initiatives like The Ellen MacArthur Foundation’s Circular Economy 100 (CE100) help companies to adopt circular practices that reduce CO2 emissions. This includes strategies such as recycling, upcycling and sourcing of sustainable materials.

Global Fashion Agenda (GFA)

The GFA is an industry forum that encourages collaboration among stakeholders to drive sustainable practices. Their ‘Fashion for Good’ initiative promotes innovative solutions for reducing emissions in production and consumption, with a focus on transparency and accountability.

Tip:

- Always find out what non-legal requirements buyers have. Do they require certification? Are they part of an industry initiative? If your buyer has requirements that differ from what you can deliver, ask if what you can do still covers their requirements.

6. Measure your CO2 footprint

The first and most crucial step in reducing your carbon footprint is measuring your CO2 emissions. There are several approaches for calculating carbon footprints, including assessing the footprint of a factory, a product or an entire supply chain. Numerous online tools are available to assist in this process. These tools provide convenient, user-friendly platforms to estimate and analyse environmental impact. Be aware that you may need to pay to use these tools.

Popular online tools are listed below.

- Carbon Footprint: This tool allows you to calculate the carbon footprint of various aspects, including personal, business and travel emissions. It provides recommendations for reducing your carbon footprint.

- Carbon Calculator by Carbon Trust: The Carbon Calculator is a free tool offered by Carbon Trust that helps individuals and organisations measure their carbon emissions across sectors like energy, waste and travel. It offers guidance for carbon reduction strategies.

- bAwear Score: This tool enables apparel brands to assess the CO2 impact of individual apparel items based on set measuring points, such as production location, raw material use, means of transport and energy sources at the manufacturing site.

- GHG Protocol: The GHG Protocol provides a standardised methodology for measuring and managing greenhouse gas emissions. Their online tools and resources assist in calculating carbon footprints for companies, products and supply chains.

- World Resources Institute (WRI) - CAIT Carbon Calculator: This tool enables users to estimate carbon emissions based on energy consumption, transportation and industrial activities. It provides global data and allows for comparisons across countries and regions.

Identify where CO2 is produced at your facility

Most online tools feature benchmark data on CO2 emissions for various products, materials and production stages. You have to generate your own data too. Start by identifying where CO2 is created in your factory, including energy use, transportation and waste. This data will be used in your CO2 calculations. Involve your team in the process of identifying sources. They might have insights on where emissions are highest. Keep your data organised and regularly updated to track progress.

Comparing Basic Carbon Data

To put things in perspective, here are some examples of basic carbon data for apparel products according to the World Resources Institute:

- The carbon footprint of producing a cotton T-shirt is approximately 4.3 kg carbon dioxide equivalent (CO2e);

- A polyester T-shirt has an estimated carbon footprint of around 5.5 kg CO2e;

- The production of a pair of jeans emits roughly 7.5 kg CO2e;

- The emissions of a cotton hoodie can reach 12 kg CO2e;

- The carbon footprint for producing a wool sweater is approximately 18 kg CO2e.

Use these benchmarks to compare and understand your carbon emissions. Double check your data entries for accuracy to ensure your calculations are correct.

Tips:

- For more details watch How to Calculate Your Carbon Footprint on YouTube.

- Measuring your carbon footprint can be done in many different ways. Make sure you choose a carbon calculation system that complies with buyer requirements. ISO 14067 is one such example.

- Begin with free tools that provide a good estimate, then consider more detailed calculations if needed. Always choose a tool that is easy for your factory to use and that meets your buyers’ needs.

7. Reduce your CO2 footprint

There are many different ways to reduce your carbon footprint. Do not only focus on large improvements like investing in more energy-efficient equipment or solar panels, but also look at relatively small changes. Moreover, do not only focus on your factory but try to convince all supply chain stakeholders to improve.

An apparel factory can implement several strategies to reduce its carbon footprint at its facilities. Here are some effective approaches:

Energy Efficiency Improvements | Older machines often use more energy. Consider upgrading to newer, more energy-efficient models. Utilising energy-efficient sewing machines, boilers and HVAC systems can significantly reduce energy consumption. Simple actions can make a big difference, like turning off machines when not in use. Ensure all equipment is regularly maintained to run efficiently and not waste energy. Install LED lighting throughout the facility to lower energy usage by up to 75% compared to traditional lighting. Install solar panels to reduce your reliance on fossil fuels. Some factories have reported achieving energy independence through solar energy. Explore local government incentives for renewable energy installations, which can reduce the initial cost. Entering agreements to purchase renewable energy from local providers can also lower a facility’s carbon footprint. |

Waste Reduction Practices | Recycle scraps and use cutting techniques that minimise waste to lower emissions associated with waste disposal. Repurpose waste materials into new products to contribute to waste reduction and emissions savings. |

| Water and Resource Management | Implement water-saving technologies, such as closed-loop water systems and rainwater harvesting. |

| Transportation and Logistics | Optimise transportation routes and reduce shipment frequency to lower the emissions associated with moving raw materials and finished products. Where possible, ship products in larger batches to reduce the number of trips required. If your buyer has not nominated suppliers, discuss sourcing materials locally, which can minimise transportation emissions and support the local economy. Try to avoid using air freight, even if deliveries are expected to be late. Encourage the consolidation of transportation and the use of green transportation methods for employees. Offer incentives for employees who use public transport or cycle to work. |

| Waste Management | Recycle materials like paper, plastic and metal to reduce waste that would otherwise contribute to CO2 emissions. Reduce the use of materials that are hard to recycle. If available, consider using waste-to-energy options, where waste is converted into electricity or heat. Track your waste streams to identify opportunities to reduce or recycle more materials. |

| Employee Engagement and Training | Involve all employees in energy-saving initiatives and create a culture of sustainability. Hold regular meetings to discuss progress and share new ideas for reducing emissions. For more details watch this Building a Sustainable Business Culture YouTube video. |

Figure 2: On average, solar panels can produce up to 2.5 kilowatt-hours (kWh) of electricity per day, depending on the weather conditions

Source: Photo by Jakub Żerdzicki on Unsplash

Source more sustainable materials

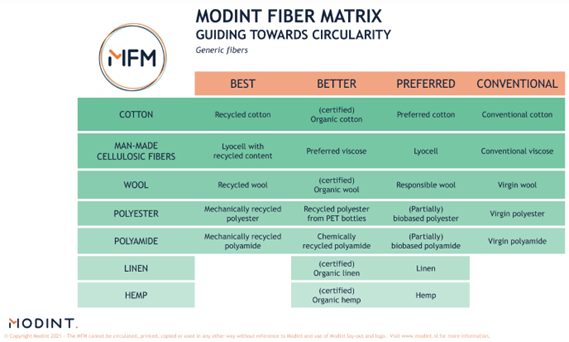

Apparel factories will need to reduce their carbon footprint by using materials that are more environmentally friendly, such as organic cotton or recycled and biodegradable synthetic fibres. The growing demand for organic cotton cultivated in a certified regenerative manner and recycled polyester underpins this need. For both materials, demand exceeds supply. This can make it difficult to secure sources. Check Modint’s Fiber Matrix below for an overview of sustainable materials.

Figure 3: Modint’s overview of sustainable materials

Source: Modint Fiber Matrix. © Modint

Help apparel brands to reduce CO2 emissions by designing for circularity

Up to 30% of the total carbon emissions in the lifecycle of an apparel item can be attributed to the waste stage, depending on factors like disposal methods (landfilling vs. incineration), recycling practices and whether or not garments are reused. This makes it important to support your buyers in making sensible decisions on the use of recycled materials in their designs, but also to develop designs that increase the life cycle of garments and make them easier to reuse, refurbish and recycle.

- Discuss the use of ‘preferred fibres’ with your buyers, including recycled fibres such as recycled polyester, recycled cotton or rPET.

- Avoid fabric compositions that are a mix of different qualities. They are less easy to recycle than items made 100% from one material.

- Use high-quality materials as much as possible (e.g. wool, mercerised cotton, cashmere). They can be mechanically recycled into new fabrics and products with no need to add stabilising qualities.

- Offer your buyer second-life options (new products made from recycled apparel), such as curtains, carpets and building materials. This will help them to think ‘circular’ when designing collections.

- Check the Circular Design Guide by the Ellen MacArthur Foundation for tips on how to make apparel designs that are easy to recycle and repair.

Tips:

- Read the CBI studies Sustainable Materials and 7 tips to go green for background information and practical guidance on making your products and your factory more sustainable.

- Read this 2023 report by the UNFCCC’s Charter for Climate Action on finding low-carbon sources for cotton and polyester. Their list of publications also includes reports on other fibres including wool.

- Check the CBI study on recycled fashion for background information and tips on the use of recycled materials and designing for circularity.

8. Share data with both buyers and internal stakeholders

It is important to share information on your progress in reducing CO2 emissions with your buyers and your staff. There are several ways to do this.

Internal Data Sharing

You can use an enterprise resource planning (ERP) system that integrates sustainability metrics into daily operations. ERP systems allow for real-time tracking and reporting of CO2 emissions data. This enables various departments to access consistent and accurate data.

Regularly update your team on CO2 reduction progress and involve them in finding solutions. Creating user-friendly dashboards that display key performance indicators (KPIs) related to emissions can help teams understand their impact and make informed decisions. Tools like Tableau or Microsoft Power BI can be used to make data trends visible.

Conduct training sessions to educate your employees on the importance of tracking CO2 emissions. This can help establish a culture of sustainability within the organisation.

External Data Sharing

Share your emissions data with buyers in a clear and honest way. Publish annual sustainability reports that detail carbon emissions data and reduction strategies to enhance transparency and accountability. Align your reports with your buyer’s preferred standards or monitoring tools. Otherwise, check reporting frameworks like the Global Reporting Initiative (GRI) and the Carbon Disclosure Project (CDP).

Engage in industry-wide initiatives, such as the Sustainable Apparel Coalition and the Fashion Pact. This will allow you to share best practices, benchmark your emissions data and contribute to collective goals. Making public commitments to reduce emissions and setting science-based targets can also encourage accountability. Companies can share their progress on platforms including the Science Based Targets initiative (SBTi).

Finally, regularly communicate with your stakeholders (buyers, local community, NGOs, government) about emissions data and sustainability efforts. This will help you build trust and support. Use newsletters, webinars and public forums.

Tips:

- Keep reports concise and focused on key metrics that matter to your buyers (see below).

- Be transparent about your progress and challenges. Buyers appreciate honesty and commitment to continuous improvement.

- Highlight areas of improvement in your reports and outline your plans for further reductions.

9. Learn from best practices

Measuring and reducing your carbon footprint may seem very complicated. Luckily, you are not the first to start this journey. Learn from the following apparel companies how you can start developing a sensible strategy.

Echotex in Bangladesh is a family-run apparel factory that started reducing its carbon emissions by replacing traditional lighting with energy-efficient LED lights and installing solar panels to power their operations. Additionally, they implemented a comprehensive waste management programme, focusing on recycling and minimising waste. These efforts led to a 40% reduction in electricity consumption, significantly lowering their carbon footprint.

Mayamiko, a small fashion brand from Malawi, focuses on sustainability by powering its production facility with solar energy, implementing water-efficient processes (e.g. rainwater harvesting) and creatively repurposing fabric scraps into accessories. These initiatives have reduced its reliance on non-renewable energy sources and minimised its carbon footprint.

Denim Expert Ltd. is a leading denim manufacturer in Bangladesh. The company is a member of the Sustainable Apparel Coalition and contributor to the ZDHC. Denim Expert published a sustainability roadmap including ambitions to save 40% energy in 2025 and reduce its overall carbon footprint by 37%. In 2023 alone, the company reduced its energy consumption by 17% and its carbon footprint by 7% by upgrading to efficient lighting, enhancing HVAC systems and using solar energy for utilities and machinery.

Considered to be one of the most sustainable denim brands in the world, Sweden’s Nudie jeans operates 29 repair shops in 19 cities globally with additional locations provided by 19 partners. The company repaired 73,368 pairs of jeans in 2023. In the same year, 93% of all fibres used were ‘preferred’ fibres (organic, certified or recycled). The brand’s website lists the average carbon emissions and water usage per product (check ‘Product Transparency’) as well as the manufacturer and supplier details for each process.

Tips:

- Begin with relatively simple changes like switching to LED lighting and integrating solar power. These initial steps can lead to significant energy savings and reduce CO2 emissions.

- Utilising solar energy and repurposing waste materials are effective ways to reduce your environmental impact and enhance sustainability.

10. Stay updated on future requirements and solutions

Staying up to date on new laws, regulations, tools, certifications and innovations aimed at reducing CO2 emissions in the apparel industry is essential for maintaining compliance and driving sustainability efforts. Some of the best ways to stay informed are listed below.

News websites

- Business of Fashion (BoF) provides updates on fashion-related policies, sustainability trends and innovations in CO2 reduction tools.

- EcoTextile News provides news on sustainable apparel, with insights on regulations, certification updates and technological advancements related to CO2 emissions reduction.

- Sourcing Journal focuses on global apparel supply chains, with specific reports on how new laws and regulations affect CO2 emissions and sustainability efforts.

Government websites

- Monitor the EU’s website for updates on legislation that affects the apparel industry, such as the Circular Economy Action Plan.

- EU Member States often provide updates through their environmental ministries or the specific regulatory authorities that deal with emissions regulations.

Sustainability and standards

- The Carbon Disclosure Project (CDP) tracks and reports on companies’ carbon reduction initiatives and emissions disclosures. Follow their updates to stay informed on corporate progress towards emissions goals.

- The Science Based Targets initiative (SBTi) helps organisations set and adhere to emissions reduction targets. It frequently releases news on policy changes, corporate commitments and certification requirements.

- The Global Reporting Initiative (GRI) tracks how companies adhere to emissions reduction frameworks. It is a reliable source for global trends and regulations.

Conferences, webinars, reports and journals

- Cascale (formerly the Sustainable Apparel Coalition) provides insights into emissions reduction tools and new industry standards, like the Higg Index.

- Fashion for Good regularly hosts webinars and events that feature discussions on new sustainability laws and trends within the apparel industry, often relating to emissions.

- The World Resources Institute (WRI) frequently publishes reports on emissions in the apparel sector and updates on regulatory changes and carbon reduction innovations.

- McKinsey is a leading consultancy firm that publishes apparel-specific sustainability reports, often highlighting emissions trends and predictions for the future impact of regulations on the industry.

Social media and news alerts

- LinkedIn allows you to follow thought leaders, NGOs, CEOs and experts focused on sustainable fashion and emissions reduction. Set alerts for updates on new laws and tools.

- Google Alerts lets you set up alerts for specific terms. Try ‘apparel emissions laws’ or ‘fashion industry CO2 reduction’ to get news directly in your inbox.

Trade associations and industry initiatives

- The Global Fashion Agenda offers reports and partnerships that keep members informed of new CO2-related regulations and trends.

- The Fashion Pact is an industry pledge network that frequently releases information on collaborative efforts to reduce carbon footprints.

FT Journalistiek carried out this study in partnership with Frans Tilstra and Giovanni Beatrice on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research