10 tips for organising your apparel exports to Europe

To get your product to the right place in Europe on time, you have to make a number of decisions: from payment terms and insurance to means of transport and packaging. This report will give you quick answers to the most pressing issues that come into play when organising a shipment of your product to Europe.

Contents of this page

- Draw up a contract with your buyer

- With first-time buyers, go for a letter of credit (LC)

- Choose the right level of responsibility for shipment and delivery

- Choose the right type of transport

- Be smart on keeping stock: not too much, not too little

- If you need to clear customs, make sure all the paperwork is done

- Always pack the goods according to the buyer’s requirements

- Get help from international support organisations

- Minimise the risk of disputes over quality

- Invest in a transparent supply chain

1. Draw up a contract with your buyer

Before you can start doing business with a European apparel company, you need to become a registered supplier. To do this, European buyers will typically give you a contract and a buyer manual to sign. The contract contains all the details of the order the buyer wants to place with you. This can be only for the first order or for multiple follow-up orders within a certain period. The buyer manual contains more general requirements that all suppliers need to comply with.

Contracts typically include information about the order (a tech pack containing the product specifications, the product’s visual appearance, quantity and total value). The buyer manual contains requirements concerning quality standards, labelling, measurement accuracy, payment and delivery terms, packing methods, insurance and documentary requirements (regarding legal compliance and customs clearance). The buyer manual also contains special provisions, for instance concerning third-party certifications.

By signing the contract and the buyer manual, you confirm that you will comply with all the requirements. This means that you will be held accountable if there is a problem after the delivery of an order. If you get into a dispute with your buyer about a delivery, the contract and the buyer manual will determine how it should be resolved. Make sure that the contract contains information about:

- Force majeure: frees one or both parties from liability or obligation if an extraordinary event (such as war, a natural disaster, strikes, riots or a crime) prevents them from fulfilling their obligations.

- Governing law: which national law applies (that of your country or your buyer’s country)

- Place of jurisdiction: the competent court in case of a dispute between the parties.

Tips:

- Confirm all orders you agree on with a written contract and check the details before signing it. Do not be afraid to ask questions or request adjustments. Buyers may think that manufacturers should just sign any contract without question, but there is always room for negotiation.

- In case of a dispute over quality or delivery, try to arrange a settlement with your buyer, for instance by reimbursing part of or the entire order. A civil lawsuit will in most cases be more expensive than a settlement. It will also make you lose your buyer.

- One of the most well-known legal requirements for exporting apparel to Europe is REACH, which stands for Registration, Evaluation, Authorisation and Restriction of Chemicals. It restricts the use of a wide range of chemicals in apparel and trims. If illegal chemicals are discovered after delivery, you will be held responsible for all expenses involved. For more information, also see the CBI study on Buyer Requirements.

- If you are selling your own designs on the European market, you must make sure you are not violating any intellectual property (IP) rights. If your buyer provides the design, they will also be liable in case the item is found to violate IP rights.

- Check the ICC’s (International Chamber of Commerce) webpage for information on common clauses and examples of contracts.

2. With first-time buyers, go for a letter of credit (LC)

The two most common payment methods in the apparel industry are the letter of credit (LC) and the telegraphic transfer (TT). An LC obligates a buyer’s bank to pay the supplier when certain conditions are met. TT refers to an electronic transfer, which can be used in an open account transaction where the funds are transferred after you have handed over the shipment. Until recently, LCs were common, but European buyers no longer favour LC payments, because these block their cash flow.

Letter of credit (LC)

However, the LC is the safest payment method for you as a manufacturer. In case of a disagreement about the shipment between buyer and supplier, the bank can hold the payment until the disagreement has been settled. Note that any change in deliverables needs to be revised in the contract, which can be very costly. Also, be aware that, if your buyer goes bankrupt or cancels the order, the LC does not guarantee payment!

Telegraphic transfer (TT)

The telegraphic transfer has many variations. For a first-time order, a buyer may agree with a down payment (for example, 30%) to finance materials. As soon as a copy of the original documents has been sent, the balance amount will be transferred and the production shipment can be handed over. After you have finished production, a copy of the original documents will be sent to the customer and the full amount can be transferred. This is called TT at site. You hand over the delivery after you receive the full payment.

However, for any further orders, many European buyers will ask for a TT after 30, 60, 90 or sometimes even 120 days. This means you as a manufacturer will finish the production and hand over the shipment to the buyer, including the original documents. The payment will be made after the number of days that you have agreed with the buyer. This is a risky payment agreement because you will take full financial risk. The goods will become the buyer’s property before you get paid.

Export credit insurance

If you want to reduce the risk of non-payment, you can take export credit insurance (ECI). This type of insurance generally covers commercial risks, such as buyer insolvency or bankruptcy, political risks, like war or civil unrest, and currency inconvertibility. An ECI lets you offer attractive open account payment terms to European buyers without having to worry about non-payment.

In case you use an ECI, be aware that every insured customer has what’s called a limit, which is the maximum amount that is insured and can be delivered on an open account base. In case you exceed this amount, the risk of non-payment is not insured. Furthermore, a credit insurance will only protect you against non-payment after handover of the shipment, but not against financial loss due to order cancellation.

Because the industry standard is that your buyer takes responsibility for transporting the goods to the country of import (see FOB in section 2 below), any insurance other than an ECI is not your concern. If you, however, agree with your buyer that you will take responsibility for transporting the goods to the country of import, you can easily buy transport insurance from a forwarding company (see below).

Tips:

- When you’re dealing with a new buyer, take no risks and only agree on an LC.

- Always assess the risk of the precise payment condition requested.

- When in doubt, check if your buyer is financially reliable by performing a credit check. Companies such as Graydon and Company Check (for the UK and Ireland) can perform such an investigation for you.

- Protect yourself against the risk of non-payment by taking export credit insurance. In most countries, this insurance service is offered by both government agencies and private insurance companies.

- Increase your liquidity and flexibility by working with a factoring company. Such an organisation will transfer up to 80% of your order value to you right after the buyer has placed the order. See, for example, Accord Financial, Fashion Factoring and HSBC.

3. Choose the right level of responsibility for shipment and delivery

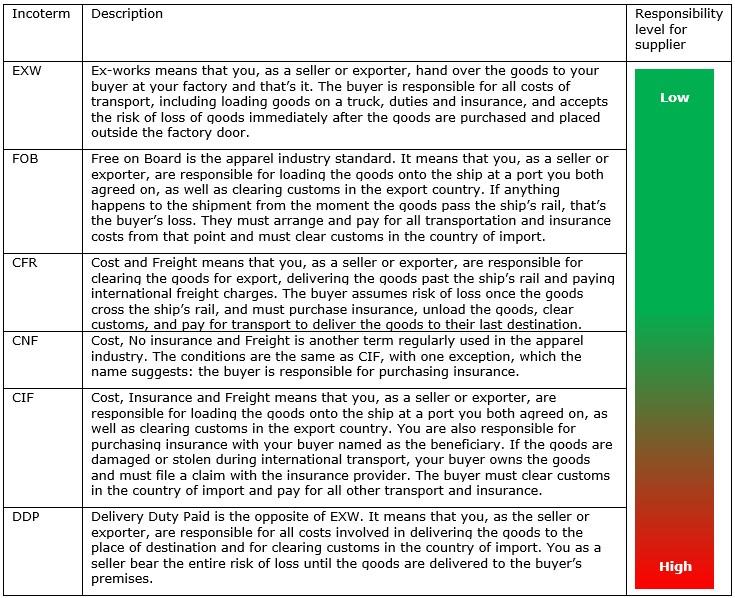

International commercial law has defined several terms to help buyers and suppliers communicate clearly about the tasks, costs, and risks associated with international transportation and delivery of goods. These terms are called Incoterms (International Commercial Terms), published by the International Chamber of Commerce (ICC). The terms determine to what extent you, as a supplier, are responsible for the shipment and delivery of an order. Ideally, your buyer takes responsibility for the shipment and delivery of the goods.

Figure 1: FOB is the standard in the apparel industry. Once the goods have passed the ship’s rail, they are the buyer’s responsibility

Photo by william william on Unsplash

Most buyers in the apparel industry will place an order using the Incoterm FOB (Free on Board). The table below explains the most commonly used Incoterms and what they mean for you as an exporter.

Table 1: Incoterms and responsibilities for suppliers

Tips:

- See the ICC’s website for more background information on Incoterms.

- Try to avoid an agreement where you, as an exporter, are responsible for transport and delivery, including clearance at customs, especially when dealing with first-time buyers. Go for FOB or EXW, since FOB is the most common and will be accepted by most buyers. In any case, avoid DDP.

Always deliver on time

If you don’t deliver on time or repeatedly fail to do so, the buyer may request a discount on the total order value, or request that you arrange an alternative means of transport to get the goods delivered on time and take responsibility for the costs.

On-time delivery is important for European buyers because they often have many different collections, sometimes more than 12 per year. These collections are based on specific colour and style themes, which means all items in the collection are presented together in the store. If an item is delivered late, then it no longer matches the theme and will be discounted almost immediately.

Tips:

- The forwarder, which is the transport company that your buyer has chosen, might load only once a week. In case of a delayed handover date, this can result in a week’s delay of the shipment. A delayed shipment might result in a discount. In case you face a problem that is caused by the fact that the nominated forwarder only ships once a week, request another forwarder with a more convenient shipping date.

- In addition to a discount for a late delivery, your buyer may also request that you arrange an alternative, faster means of transportation to get the goods delivered on time, for example, by air. Be prepared: your buyer might ask you to pay for the cost (see section 3 below on the cost of transportation). In this case, do not forget to request the buyer to deduct the sea shipment costs.

4. Choose the right type of transport

If you, as the seller or exporter, have agreed with your buyer on an Incoterm under which you take care of the delivery and payment of transportation, such as DDP or CFR, you need to choose the right type of transport. In most countries, there are several modes of transportation and delivery for taking your product to your customer. Each type of transport has its advantages and disadvantages.

Table 2: A comparison of the benefits of different modes of transport

| Sea shipment | Air shipment | Trucking | Train | |

| Speed | (+) | (++++) | (++) | (+++) |

| Costs | (++++) | (+) | (+++) | (+++) |

Depending on the country where your factory is located, you can choose to transport your goods in the following ways:

- Freight container shipment by sea

- Freight container shipment by air or sea

- Transport by air

- Transport by truck

- Transport by train

- A combination of the above

Speed and cost of transport

When deciding on the best type of transport, speed, price and availability will be your most important considerations. Transporting a container by ship from Asia to Europe, for instance, can take anywhere between 30 and 40 days. By air, it might only take 4 to 7 days, but the financial cost will be a lot higher. Despite rapidly rising shipping costs, air freight is still 5 to 10 times more expensive per piece than ocean shipment. In general, air freight starts to make sense when the cost of transport is less than 15% to 20% of the total value of the goods. With apparel, this is rarely the case.

The price difference between different types of transport depends on:

- location

- peak season

- gas costs

- dollar exchange rate

- external factors, such as weather and risk

Because several of the factors mentioned above can change overnight, so can transport tariffs. You should regularly check the latest prices of different types of transport. Compare also the rates of different transport companies to make the best choice.

Sustainable transport

The carbon footprint of apparel production includes the impact of transport. It is important to always consider the impact of transport on the environment when selecting a transportation company:

- Air transport might be fast, but it has a relatively high environmental impact. It can be a useful option if you need to compensate for delays or if you need to ship batches smaller than a container load.

- Choose an international maritime shipping company that uses biofuels to reduce its carbon emissions. Also follow the latest developments in electrical shipping and try to convince your buyers to use a sustainable alternative for regular container transport by sea.

- For some destinations, railway transport can be a good sustainable alternative for regular container transport by sea.

- For first-mile transport, choose electric vehicles over petrol-powered vehicles.

Tips:

- Use the Freightos International Freight Rate Calculator to compare the cost of transport by air, sea or land.

- See Cogoport or the Freightos Container Shipping Cost Calculator to compare sea freight rates and get quotations from more than 70 international shipping lines.

- If you decide to use sea transport, consider the size of the shipment. In case of FCL delivery (full container load) the transport costs per piece will be lower than in LCL delivery (less container load). However, if you don’t expect to fill up an entire container, LCL is probably cheaper. The commonly used freight container is 20-feet long, or 33.2 m3 in volume. This is also called 1 TEU, a twenty-foot equivalent unit.

- In case of a delayed delivery, check on arrival dates of alternative forwarders. Some nominated forwarders only load once a week. Others might load multiple times per week, giving you a few more days until handover.

- In case you are unable to handover the goods on time to the nominated forwarder, then discuss with your customer the option to use alternative forwarders that enable you to handover later.

- Use the EU’s Sustainable Transport platform to learn more about the environmental impact of different means of transport. If you want to calculate your own carbon footprint, consultancies such as The Carbon Trust and the Climate Neutral Group can help. They can also advise you on how to reduce or offset your impact.

5. Be smart on keeping stock: not too much, not too little

As a manufacturer, you will regularly have to store fabrics, trims and ready-made garments until the handover date. This is both an advantage and a disadvantage. By keeping stock of fabrics and trims your reaction time and production speed will improve substantially. On the other hand, stock can degrade, get damaged or even disappear. Try to reduce stock to a minimum with efficient supply chain planning, for example, using STYLEman and MRPeasy.

Tips:

- Having too much stock will influence your cash flow but having no stock will influence your production speed. Calculate your production and keep a one-week margin for stock in case of a new production run.

- Always check the stock position of nominated suppliers of labels and trims.

- If buyers ask you to keep stock, make sure they sign a contract with a due date for the stock to be used by the buyer and a payment arrangement. Ask your buyer for financial support to finance your stock service. At the very least, ask a storage fee. In case your country has a rainy season, keep your goods in a dry room. Shipping damp or wet goods will always cause bad smell or even worse: mould. In this case, your buyer will either claim, return or recondition the goods, which will be costly.

6. If you need to clear customs, make sure all the paperwork is done

As highlighted above, try to avoid the responsibility of arranging transport, delivery and clearance of goods in the country of import, especially if you have no experience in these matters. There is a lot of paperwork involved and the financial risks are high. If you still agree to take this responsibility, you can use a forwarding agency to do the job. Otherwise, you need to make sure yourself that you comply with the EU’s custom requirements.

If you are looking for a forwarding company to arrange transport for you, the website Freight Finders lets you compare shipping costs of different forwarders. You can also try the following companies, but remember to always compare different offers:

- Instafreight from Germany

- International Forwarding Limited from the UK

- FedEx from the US

If you want to arrange for transport yourself, you need to follow EU import procedures. You will need the following documents to clear customs in the EU. Each document needs to comply with very specific requirements. Read about them on the website of the EU Trade Helpdesk.

No import duties for countries under the Generalised Scheme of Preferences (GSP)

A group of 75 countries fall under the EU’s Generalised Scheme of Preferences (GSP), which removes import duties on products coming into the EU market. The idea is to support developing economies to alleviate poverty and create jobs based on international values and principles, including labour and human rights. Exporting from a GSP country can have a substantial financial benefit for your buyer.

The EU offers three schemes:

- Standard GSP: a partial or full removal of customs duties on two-thirds of tariff lines.

- GSP+: an incentive arrangement for sustainable development and good governance. It slashes tariffs to 0% for vulnerable low and lower-middle income countries that implement 27 international conventions related to human rights, labour rights, protection of the environment and good governance.

- EBA (Everything but Arms): an arrangement for least developed countries, providing them with duty-free, quota-free access for all products, except arms and ammunition.

Tips:

- Check if your country is one of the 75 countries that falls under the GSP.

- If you are supplying from a country on the GSP list, advertise yourself as such.

- See the EU’s Acces2Markets website for information on the tariff for importing apparel into the EU from your country.

- Always send the concept documentation to your customers import department for approval before handing over the official documents.

- In case you do not belong to the list of GSP countries, consider establishing a business relationship with a factory within one of these countries to offer your buyer different options.

7. Always pack the goods according to the buyer’s requirements

In most cases you will receive a packing manual from your buyer. Not complying with the requirements in the manual will lead to a claim as the goods need to be re-packed, which is costly. In the manual, you will find all relevant packing instructions, such as:

- type and quality of the packing material you need to use;

- size of the packing material;

- information that should be mentioned on the packing material;

- placement and position of barcodes;

- way of stacking or hanging (preferred for leather items);

- maximum quantity in a box or polybag;

- maximum weight of an export carton;

- nominated suppliers for the packing material.

What information should be on the packaging?

Your buyer will confirm what should be on the packaging. Most of the information that needs to be on the packaging is determined by the legally required packing list. Your buyer will also probably have specific requests regarding style references and numbers, size breakdown, number of pieces and colourways.

A special concern for buyers is moisture, which can lead to bad smells, spots, stains, mould or mildew and loss of sheen (in leather items). A common requirement in the apparel industry is that goods should be stored, packed and shipped in dry, well-ventilated conditions. The use of proper ventilation and dehumidifiers during storage and in containers can prevent moisture damage. Packing goods with silica gel packets can further reduce excess moisture during shipment.

The future of packing: sustainable packaging materials

The European Commission and the European fashion industry have a strong commitment to reduce the environmental impact of packaging and packaging waste. A new revision to the EU’s legislation on packaging aims to restrict unnecessary packaging, make all packaging in the EU fit for recycling by 2030 and promote the reuse of packaging.

Meanwhile brands, retailers and packaging suppliers are working hard on sustainable alternatives to conventional materials like cardboard and polyester. When it comes to end-consumers, Drapers revealed in 2021 that 77 per cent of European customers want as little packaging as possible.

You can tap into this trend by using less packaging materials. This will not only save costs but will reduce the impact of packaging on the environment. Another option is to use environmentally friendly versions, such as recycled, biobased and biodegradable materials.

Tips:

- When using carton, get the FSC-certified version. This ensures the carton originated from responsibly managed forests or recycled materials. Try to replace polyester materials by using recycled polyester or biodegradable plastics. This white paper by Fashion for Good offers tips on reducing the use of polybags (PDF), as well as on how to recycle them or replace them with sustainable alternatives.

- Always ask permission from your buyer before using alternative packaging and materials.

- Ask your buyer if hangers and individual polybags are necessary.

- See Packaging Europe, Springwise or MaterialDistrict (type ‘packaging’ into the search bar) for background information, best practices, trends and innovations in sustainable packaging, including biodegradable and recycled packaging materials.

8. Get help from international support organisations

In case you are still uncertain about how to comply with all legal and non-legal requirements concerning packing, transporting and delivering goods to Europe, it is good to know that there are several international organisations that can advise you on these matters.

The following organisations can help you be successful in international business:

- In addition to market intelligence reports, CBI offers export coaching to SMEs in 35 countries. See the CBI website for an overview of current apparel programmes.

- The International Trade Centre (ITC) is a joint initiative of the WTO and the UN. It provides market intelligence, matchmaking and business consultancy to SMEs in developing economies.

- The EU’s Access2Markets trade helpdesk is an easily accessible online guide to the rules you need to follow when exporting goods to one of the 28 member states of the EU Customs Union.

- The Institute of Export & International Trade is a UK organisation offering help with anything from customs and VAT procedures to payment terms and contract issues.

- Open Trade Gate is Sweden’s online information centre for companies in developing economies that want to export to Europe, offering technical assistance and information on export procedures. Fill in the online inquiry form and they will answer any question you have on these matters.

In addition to the international trade helpdesks mentioned above, there are several organisations and consultancies that can answer industry-specific questions on exporting apparel to Europe:

- Investigate if your country has a support organisation for exporting apparel to Europe, such as India’s AEPC, Egypt’s ETDA and Ethiopia’s ETIDI. Check also your local chamber of commerce.

- The International Apparel Federation (IAF) is a member organisation offering help with logistics and legislation. Its website shows an overview of all its national member associations, including textil+mode (Germany), UFIMH (France) and UKFT (UK).

- Other organisations that regularly offer coaching programmes for apparel exporters in developing economies include the UNDP, DFID, DANIDA, ITC, GIZ, SIPPO, ICCO and Solidaridad.

- PUM is a Dutch NGO that offers practical support by senior apparel industry experts on anything from business process management to arranging your exports.

- UK consultancy Edited offers advice on market trends. Swiss consultancy Gherzi and Dutch consultancy Forward in Fashion offer advice to apparel companies regarding the textile value chain and export strategies. McKinsey offers consumer market insights and expertise in apparel, fashion and luxury.

Tips:

- Always research the specific legal requirements you need to comply with before starting to export.

- Use the service of supporting organisations to help you overcome lack of experience.

- Investigate if your potential buyer has a local office that can help you comply with export requirements.

- Finding a consultant that can help you set up an export strategy or improve your production process can be easily done on LinkedIn, for instance. Search for a ‘fashion manufacturing consultant’ plus the country you are targeting. Combine with your own country if you are looking for a local consultant.

9. Minimise the risk of disputes over quality

Every shipment to Europe will be inspected on arrival by the forwarder and by your buyer. In case the goods arrive damaged, it is important that you can trace back when and where the damage occurred and who caused the damage, so as to prevent any unjust claims.

Tips:

- Agree with your buyer on an AQL (acceptable quality limit), which refers to the quality level that is worst tolerable. For instance, AQL 2.5 means that your buyer will reject a batch if more than 2.5% of the whole order quantity over several production runs is defective.

- Make sure you agree with your buyer on an approval protocol for anything from fabrics, trims, and samples to ready-made garments. Confirm with your buyer that they have approved everything before you ship the order.

- Always take pictures of the shipment before you hand it over.

- If you want to be extra sure, you can always ask an external party to inspect the shipment on quality and packing. See, for example, the inspection services offered by SGS.

10. Invest in a transparent supply chain

Demand for transparency and traceability in the fashion supply chain is growing in Europe. An important reason for this is that the European Union is introducing new legislation on due diligence and reporting. It is therefore wise to invest in creating a fully transparent supply chain. This means you will need to investigate where your suppliers are sourcing their materials and how they are processing them. You may also need to invest in tools that can track and trace the origins of your products.

While most European buyers agree that transparency is important, many companies are still struggling to make their supply chains transparent. So offering opportunities for transparency can give you a serious competitive advantage.

Several online tools can help you map your supply chain. OpenSupplyHub is a collaborative platform used by various stakeholders in the sector. Commercial options include SupplyShift, Chainpoint, String3 or Tex.Tracer. Other platforms can be used to map, calculate and monitor the CSR performance of your supply chain, such as ISEAL, SIM Supply Chain, GSES, Ecovadis and Ecochain. Platforms like these are often used by European buyers.

Tips:

- Supply chain mapping tools can be costly and quite complicated to use, so always ask your buyers for advice on what systems they use.

- Check the Fashion Transparency Index by Fashion Revolution for background information on the growing demand for transparency and the transparency scores of major fashion retailers.

- The website of the Transparency Pledge offers a list of signees, showing you which brands focus on transparent supply chains. If you want to verify that one or more input materials are in a final product, you can use the Textile Exchange’s Content Claim Standard (CCS). This is a third-party verified chain of custody standard.

Further reading

The CBI apparel study on buyer requirements will help you understand the most important requirements in the European market.

In addition, the CBI apparel study ‘10 Tips for Doing Business With European Buyers’ will help you understand what is needed to successfully approach a potential buyer and how you can develop a long-lasting business relationship with them.

This study was carried out on behalf of CBI by Frans Tilstra and Giovanni Beatrice for FT Journalistiek.

Please review our market information disclaimer.

Search

Enter search terms to find market research