8 tips on how to become more socially responsible in the apparel sector

Socially responsible apparel manufacturers want to minimise their negative impact on society, people and the environment. At the same time, they want to maximise their positive impact. More and more buyers, end consumers and regulators are demanding that businesses operate in an ethical and sustainable manner. As a result, social responsibility has become an important thing to think about. Being socially responsible can become your unique selling point (USP) if you inform buyers about how your company is doing better than your competitors in this area.

Contents of this page

- Familiarise yourself with the many aspects of social responsibility

- Provide a safe working environment and invest in a healthy workforce

- Make sure you are paying a living wage

- Aim for a gender equal and inclusive workforce

- Don’t forget to manage social risks in your own supply chain

- Get the right certifications

- Familiarise yourself with your buyers’ due diligence obligations

1. Familiarise yourself with the many aspects of social responsibility

European buyers will expect you to comply with international agreements on labour rights. The most important agreements on the protection of labour rights are the conventions and recommendations issued by the International Labour Organization (ILO), a United Nations (UN) agency. The 11 fundamental ILO conventions deal with topics such as freedom of association, forced labour, equal pay and safe working conditions.

The ILO conventions form the inspiration for many other standards and codes for the protection of labour rights, including the Ethical Trading Initiative’s Base Code.

Table 1: The most basic international labour rights

| Labour topic | Labour right |

| Recruitment and hiring | People should be free to choose employment at your company and be free to leave, after having given reasonable notice. Forced, bonded or involuntary labour is not allowed. |

| Working hours | Employees may not work more hours in a standard working week than is legally allowed. Working more than 60 hours in a 7-day week should only occur in exceptional circumstances. Overtime should be voluntary and compensated at a minimum rate of 125%. Employees should have at least 1 free day per 7-day period (or 2 days in a 14-day period). |

| Wages and secondary benefits | Companies should pay the minimum legal wage or the industry benchmark for a standard working week, whichever is the highest. Companies may not discipline employees by deducting payment. |

| Worker treatment | Child labour is not allowed. Companies may not discriminate based on race, caste, national origin, religion, age, disability, gender, sexual orientation, marital status, union membership or political affiliation. These factors may not play a role in recruitment, payment, promotion or any other form of employee benefit. Companies should facilitate freedom of association of employees. Physical abuse and intimidation are not allowed. |

| Health and safety | Companies should provide a safe and hygienic working environment (including clean toilet facilities). Employees should also receive regular training on occupational health and safety to prevent accidents. |

| Employment practices | Employers should respect local labour laws. They should not try to avoid their obligations under these laws. |

Changing definition

Thanks to conventions and standards, there is a common understanding in the industry when it comes to the meaning of social responsibility. But this definition can change. Buyers, regulators, NGOs and other stakeholders have emphasised different aspects of social responsibility over time. In recent years, for instance, living wages and transparency have received a lot of attention. Many apparel buyers from Europe will want to know about your performance in these areas before doing business with you.

Beyond international conventions

Apparel manufacturers may decide to invest more in particular social causes. Many factories have developed their own corporate social responsibility (CSR) policy or code of conduct. In these documents, companies explain how they are being socially responsible. A CSR policy can cover topics such as hiring practices, training and career

Tips:

- Study the ILO conventions, the Ethical Trading Initiative’s Base Code or the Global Reporting Initiative’s (GRI) list of standards for reporting on (social) impacts to learn about all aspects of becoming socially responsible.

- Read more about the history of social responsibility in the apparel industry in the CBI study on the sustainable transition in apparel and home textiles.

- Read more about buyer requirements, including requirements for social responsibility, in the CBI study What are the requirements for apparel to enter the European market?

There are many benefits for apparel manufacturers who work in a socially responsible manner. Buyer requirements can be a strong motivation to treat your employees and your community fairly, but that should never be the only reason to do so. The most important advantages of running your business in an ethical manner are listed in the table below.

Table 2: Why you should operate your business in a socially responsible manner

| Area of social responsibility | Benefit |

| Attracting and retaining talent | Operating in a socially responsible manner makes it easier to attract new talent. It also increases employee loyalty, which makes employees less likely to quit. This protects the investments you make in your staff (for instance by offering training). |

| Improving financial performance | Companies that prioritise social responsibility often improve their financial performance because they are better able to manage risks, reduce costs and access new revenue streams. |

| Meeting regulatory requirements | Companies must comply with a growing number of national and international laws and regulations related to the protection of labour rights and the environment. By doing so, your company will avoid legal problems. |

| Meeting buyer requirements | Apparel buyers also aim to operate in a socially responsible manner. Purchasing from socially responsible factories is an important part of the corporate social responsibility policies of many European buyers. |

| Building trust with end consumers | End consumers are becoming more and more concerned about the social and environmental impact of the products and services they buy. By showing their commitment to social responsibility, companies can build trust with their end consumers and improve their brand reputation. |

| Protecting human rights and promoting fair labour practices | By showing social responsibility in this area, companies can make a meaningful contribution to the wellbeing of their employees, their community and global society. |

Best practices

The number of socially responsible apparel factories is growing worldwide. Some factories adhere only to minimum requirements, such as local labour laws and standards they must meet to do business with European buyers, like those of amfori BSCI. Other factories invest in social responsibility, making it part of their marketing and setting themselves apart from more conventional factories. The companies below are examples of exporters that have made social responsibility their USP.

Stanley/Stella is an apparel production group based in Brussels, Belgium, that works together with 10 factories in Bangladesh and China. According to its code of conduct, which is based on the fundamental ILO conventions, Stanley/Stella is committed to the ‘highest standard of sustainability’. The company has been awarded ‘leader status’ by the Fair Wear Foundation and is working with its suppliers to guarantee a living income for their employees. By investing in charitable projects, Stanley/Stella supports local communities, for instance by improving access to clean drinking water.

Yevu Clothing is a social enterprise founded in 2012 in Accra, Ghana. Its purpose is to be competitive on the world market and at the same time to provide women in Ghana with full-time jobs that provide a living wage, dignified work, guaranteed healthcare and social security. Yevu pays its employees above urban Ghana’s living wage benchmark and the company invests in the technical skill set of its team. Yevu claims steady growth and a 100% employee retention rate, thanks to its socially responsible business strategy.

Ethiopian Desta Garment promotes itself as an ‘ethical garment manufacturer’. The company is OEKO-TEX® STeP-certified and provides its employees with many secondary benefits, such as free lunches and medical services. Desta makes a special effort to employ disadvantaged people, including people with a disability. Around 25% of its management consists of women. The company communicates transparently about its CSR policy and shares video interviews with its employees online.

Tips:

- Develop a CSR strategy and share this with your buyers and prospects.

- Create a working environment in which employees can regularly share thoughts and complaints, without the threat of negative consequences.

2. Provide a safe working environment and invest in a healthy workforce

Almost 2 million people die each year and more than 4% of global GDP is lost due to work-related diseases and injuries. Investing in health and safety will lead to a wide range of direct and indirect benefits for your business. Your employees will be happier, productivity will improve and there will be fewer work accidents and less sick leave. You will also benefit from higher employee retention, better product quality, a better brand reputation and increased market access.

Table 3: Investing in occupational health and safety (OHS) has a range of benefits

| Area of social responsibility | Benefit |

| Productivity | A safe and healthy work environment will increase employee morale, leading to higher productivity and lower absenteeism. |

| Brand reputation | Companies that prioritise health and safety are often seen as responsible and trustworthy, improving their reputation. This will attract buyers who value sustainability and ethical business practices. |

| Legal security | Adhering to health and safety standards and regulations will reduce the risk of legal liability and costly lawsuits in the event of an accident or injury. |

| Employee retention | Providing a safe and healthy work environment will improve employee satisfaction and lead to lower turnover, reducing training and hiring costs. This will result in a more consistent product quality level. |

| Supply chain management | Implementing strong health and safety standards in the supply chain can improve supplier relationships. It also reduces the risk of supply chain disruptions. |

| Market access | Companies that prioritise health and safety are often preferred by international buyers, providing access to new markets and customers. |

Figure 1: Provide a clean, well-kept workspace for your employees, with plenty of daylight

Source: Forward in Fashion

Occupational health and safety (OHS) programmes

To guarantee a safe and healthy working environment for their employees, companies should develop and implement an occupational health and safety (OHS) programme. This programme should cover all aspects of health and safety in the workplace, as described in the ILO recommendation on OHS (No. 164, 1981: see Article IV). Every apparel factory should:

- provide and maintain workplaces, machinery, equipment and work methods that are as safe as reasonably possible. This means regular maintenance and inspection of machinery and equipment and regular evaluation of operational procedures;

- maintain a clean and hygienic workplace. Regular cleaning and disinfection of the workplace, hand washing facilities and other hygienic measures help prevent the spread of diseases;

- give all employees the necessary instructions and training to work safely;

- provide employees with adequate personal protective clothing and equipment (PPE) such as gloves, masks and eye protection to prevent exposure to hazardous materials. Employees should not have to pay for PPE themselves;

- ensure work shifts with reasonable working hours and enough rest breaks;

- take measures to prevent excessive physical and mental fatigue among employees;

- stay informed about the latest OHS recommendations.

Special measures to prevent (the spread of) diseases

The coronavirus pandemic has taught factory operators worldwide the importance of maintaining a hygienic working environment. To minimise the risk of infection for your employees and prevent excessive sick leave or even shutdowns:

- provide clean water for all employees;

- provide free hand sanitiser;

- provide protective face masks with a filter (read this fact sheet by McKinsey for an overview of the available masks and their protection levels);

- create clear company policies on hygiene;

- instruct employees on the importance of personal hygiene;

- for more detailed guidelines, see ILO’s checklist for the prevention of Covid-19.

Tips:

- See the ILO’s Code of Practice on safety and health in textiles, clothing, leather and footwear for practical tips on how to develop your own OHS programme.

- For a detailed analysis of OHS risks in the garment and textile industry, read this article.

- European apparel buyers may require certiconditions. Make sure you meet the requirements and communicate this clearly to (potential) buyers.

- Encourage your employees to maintain healthy habits during and after work, such as regular exercise, healthy nutrition and adequate rest. Make sure your factory setup and working hours support this. Offer healthy, high-nutrition foods in your canteen and opportunities for people to exercise during brfication for international OHS standards, such as ISO 45001. They may also require regular inspections and audits of working eaks.

- To promote a productive, safe work environment and a happier workforce, familiarise yourself with work floor management systems such as Kaizen or the 5S system.

3. Make sure you are paying a living wage

It is estimated that only 10% of the circa 60 million employees in the apparel production industry are being paid a living wage. A living wage allows an employee with a normal working week to afford a decent standard of living for themselves and their family. This means they can afford food, water, housing, education, healthcare, transportation, clothing and other essential needs, and that they are able to save money for unexpected events. Earning a fair wage in pursuit of a decent life is a basic human right.

You should at least pay your employees the legal minimum wage or follow the industry benchmark if no legal minimum wage is set. Note, however, that minimum wages are often well below the living wage. Fair wages are different everywhere, so the wages you pay should be calculated specifically for apparel workers in your region (see tips below for guidance).

More and more European buyers find it important that factories pay their employees a living wage. This is reflected in the social certification standards most of them use. amfori BSCI now works together with the Platform Living Wage Financials to promote fair remuneration by raising awareness and providing useful tools. The Ethical Trading Initiative and SA8000 also draw attention to the importance of living wages by including fair pay standards in their requirements.

Tips:

- If you want to calculate the living wage in your country or region, you can use the Fair Wear Foundation’s Wage Ladder or the WageIndicator Foundation’s Living Wage Indicator. You can also use amfori BSCI’s Fair Remuneration Quick Scan to calculate a living wage for your employees.

- More information about living wages, best practices and action plans is available on the websites of the Global Living Wage Coalition and RVO.

- If you want to set up a living wage project for your employees, take inspiration from Dutch workwear manufacturer Schijven.

- Consider offering your employees secondary benefits, such as free lunches, free transportation, free medical services, free day-care and grocery discounts.

4. Aim for a gender equal and inclusive workforce

Women make up 80% of the workforce in the global apparel industry, but they suffer the most from discrimination, harassment and a general lack of career opportunities. Many social, ethnic and religious minorities and disabled people suffer the same fate. Creating a supportive and inclusive work environment will benefit your employees and your business. Aim for equal opportunities and compensation at every level of your organisation.

A workplace that values and embraces diversity can see a wide range of benefits, from improved decision-making and problem-solving to increased creativity and innovation. One important aspect of diversity is social diversity, which refers to differences in race, ethnicity, gender, religion and sexual orientation. These differences can offer a wealth of perspectives, experiences and ideas, helping organisations to better understand and serve the needs of their customers and employees.

Creating an inclusive work environment can be challenging

Achieving social diversity in the workplace can be challenging. We all have beliefs about certain groups of people that can influence our judgements. Sometimes we are not even aware that we have these beliefs. To create a truly inclusive workplace, try to create a culture that values and respects diversity. This may involve diversity training for employees, the creation of employee resource groups or the implementation of inclusive policies and practices.

Practical guidance

What can you do to create a workplace culture that values and supports diversity, where all employees feel respected and included?

- Encourage open and respectful communication and provide a safe space for employees to express their opinions and share their experiences.

- Ask your employees for input. Create and share a diversity and inclusion policy that outlines the steps your company will take to achieve its goals in this area. Regularly seek feedback from employees on your company’s diversity and inclusion initiatives and make changes based on their suggestions and needs.

- Ensure a diverse workforce by giving job opportunities to a broad range of candidates and providing equal opportunities to all employees.

- Ensure that leadership positions are filled by a diverse range of people in terms of background, gender and ethnicity.

- Ensure that employees who do the same work receive equal pay and benefits, regardless of their race, gender or other personal characteristics.

- Provide flexible work arrangements. Allow your employees to work remotely if possible and create flexible schedules to support employees with diverse needs and responsibilities.

- Provide training for all your employees on diversity and inclusion, including unconscious bias, cultural competence and other related topics.

- Regularly monitor and evaluate the effectiveness of diversity and inclusion initiatives, for instance by organising anonymous surveys. Make changes where necessary to ensure continued progress. Study and compare factors such as motivation, sickness, loyalty, dedication and quality of work.

Best practices

The companies below prioritise social responsibility and have made it part of their marketing. This gives them an advantage when competing with more conventional factories for orders from European buyers looking for sustainable suppliers.

Soko is a Kenya-based company that creates sustainable fashion and jewellery. It works with local artisans to create products that are environmentally friendly and ethically produced, paying a living wage to all its employees. Through its Kujuwa Initiative, Soko provides training and support to young people, families and educators to promote sexual reproductive health and rights and menstrual hygiene. Soko produces and distributes washable sanitary pads by upcycling fabric waste.

Entoto Beth is an Ethiopian Fairtrade-certified factory that produces textiles, leather bags and accessories. It was established in 2012 as a social enterprise. Its objective is to create beautiful products (in some cases using recycled gun shells) while empowering and employing HIV-positive women. Founder Bethlehem Berhane wanted to help these women restore their dignity and offer them a way to provide for themselves and their families. The company currently employs 250 people, of whom 150 are HIV positive women.

Eclat is a Taiwanese apparel production group with factories in Taiwan, Vietnam and Cambodia. It invests in sustainable production methods and an inclusive working environment. In 2019, the ratio of women serving in managerial positions at Eclat was 45.43% in Taiwan, 75.62% in Vietnam and 84.51% in Cambodia. Eclat also participated in the IFC’s Gender Equality and Returns (GEAR) programme, training female employees in leadership skills.

Tips:

- For guidance and best practices when it comes to gender-inclusive policies, see the BetterWork programme’s gender equality and inclusion initiatives or the Gender-Responsive Due Diligence platform.

- For practical tips, see the ILO’s Sustaining Competitive and Responsible Enterprises (SCORE) training programme, which has improved productivity at participating SMEs by up to 50%.

- To get a good idea of what type of measures apparel companies can take, read Fair Labor’s Investigations Reports. Fair Labor handles third-party complaints about CSR risks at apparel factories worldwide.

5. Don’t forget to manage social risks in your own supply chain

Being a socially responsible apparel manufacturer starts with implementing CSR policies in your own factory. The next step is to develop a sourcing strategy that ensures that your suppliers also adhere to the ethical, legal and reputational standards that you, your buyers and your end consumers have set. This requires a fully transparent supply chain, which can be very challenging for SMEs. Prioritise your own needs and actions and start by taking small steps.

Table 4: Benefits of supply chain transparency

| Impact topic | Benefit |

| Business ethics | The apparel industry is often associated with labour and human rights abuses, including poor working conditions, long hours and low pay. Supply chain transparency can help companies identify and address these issues and ensure that their suppliers are complying with ethical standards. |

| Legal compliance | Companies must comply with a range of laws and regulations related to labour, environmental protection and health and safety. Supply chain transparency can help companies ensure that they are meeting their legal obligations and avoid the risk of legal liability. |

| Sourcing strategy | By providing suppliers with clear standards and requirements and regularly discussing the topic of social responsibility with them, companies can improve their relationships with suppliers and reduce the risk of supply chain disruptions. |

| Reputation management | Companies that are transparent about their supply chains are often seen as more responsible and trustworthy. This improves their reputation and attracts customers who value sustainability and ethical practices. |

| End consumer demand | End consumers are becoming increasingly concerned about the impact of their purchases on people and the environment. Supply chain transparency can help companies demonstrate their commitment to responsible and sustainable practices. |

The first thing you should do is assess the CSR risks that may occur within your own supply chain, such as social, environmental and ethical risks. A helpful tool is the freely available CSR Risk Check. This online database lets you select specific product categories based on Harmonised System (HS) codes (including apparel and textiles), combined with a production location. The tool then generates a list of potential risks and tips for prevention and mitigation, based on open sources of information. Make it a habit to use the Risk Check regularly.

After learning more about your CSR risks, you may take the following steps:

- Develop clear selection criteria for your suppliers, taking into account their compliance with social, environmental and ethical standards. Conduct regular audits of suppliers to monitor their performance and identify areas for improvement.

- Develop and implement a due diligence process to assess and monitor suppliers’ compliance with your company’s standards and requirements.

- Create contracts for suppliers that include clear standards and requirements for health and safety, labour rights and environmental protection.

- Provide training and support to suppliers to help them improve their performance and comply with your company’s standards.

- Stay in regular contact with suppliers to discuss their performance, identify areas for improvement and address any concerns.

- Establish a complaints procedure for workers and other stakeholders that allows them to report violations of your company’s standards and requirements.

- Collaborate with other stakeholders, including NGOs, governments and industry organisations, to improve supply chain practices and address common risks.

- Continuously monitor and improve supply chain practices, including through regular risk assessments and audits. Ensure that your company remains compliant with its own standards and requirements.

Tips:

- Use the OpenSupplyHub, an online open-source supply chain map. The website lists thousands of apparel manufacturers and suppliers worldwide, with information often provided by buyers or NGOs. You can use it to find, add or share basic information about your suppliers.

- See the CBI study 10 tips for doing business with European buyers for tips and suggestions on collaborating with stakeholders to improve your (ethical) sourcing.

- There are several online tools that can help you map your supply chain. These platforms are often used by European buyers and can be quite complicated. Always ask your buyers what systems they use. Examples include Supply Shift, Chainpoint, String3 and Tex.Tracer. Other platforms, such as ISEAL, SIM Supply Chain, GSES, Ecovadis and Ecochain, can be used to map, calculate and monitor the CSR performance of your supply chain.

6. Get the right certifications

Many buyers in Europe are setting stricter rules for social responsibility. The minimum requirements are that you must allow buyers to inspect your factory and that you follow a code of conduct that states that you comply with local laws. Buyers may also demand that you follow specific social standards. Sometimes this requires third-party certification.

There are several standards and certifications in the textile industry that aim to encourage fair treatment of workers in garment manufacturing. Below are some of the standards most requested by European buyers.

- BSCI (Business Social Compliance Initiative). This is the most popular standard among European buyers, and it is often the only one they will require. BSCI is a supply chain management system that helps manufacturers improve social compliance.

- The following social and environmental standards are especially popular in the UK: WRAP (Worldwide Responsible Accredited Production), SEDEX and ETI (Ethical Trade Initiative).

- Other popular standards that guarantee that apparel is made with respect for workers’ rights are the SA8000, ISO 26000, FWF (Fair Wear Foundation) and Fairtrade.

Table 5: The most used social standards in Europe

| Name of standard | Logo | Type | Cost for manufacturers | Further information on getting certification |

| amfori BSCI | Social | External audit costs (variable) | By buyer invitation; amfori provides a list of organisations that can perform an audit | |

| SA8000® |

| Social | External audit costs (variable) | Learn more about the SA8000 certification process here |

| WRAP | Social | €1,030 registration fee + external audit costs (variable) | Learn more about the WRAP certification process here | |

| Sedex | Social, environmental | €118 per year per site + external audit costs (variable) | Learn more about the Sedex certification process here (PDF) | |

| Fair Wear |

| Social | Membership is not open to factories (yet) | See which brands are members |

| B-Corp |

| Social, environmental | €865 per year minimum | Learn more about the B-Corp certification process here |

| OEKO-TEX® STeP |

| Social, environmental | Certification fee + external audit costs (variable) | Learn more about the OEKO-TEX® STeP application process here |

| GOTS |

| Social, environmental | €150 per year minimum + external audit costs (variable) | GOTS provides a list of organisations that can perform an audit |

Figure 2: Let (potential) buyers know about how you are certified

Source: FT Journalistiek

Tips:

- For more information on (social) standards, see the ITC’s Standards Map. It contains detailed profiles of more than 300 widely used standards.

- To get a quick evaluation of your social performance, fill out amfori BSCI’s self-assessment.

- Ask your buyers what standards they want you to comply with. Be aware that complying with a standard costs time and money – not only for the application and the audit, but also for the annual renewal. Because many standards have overlapping criteria, a few simple interventions will often make your factory compliant with more than one standard. Talk to your buyers about these kinds of interventions to avoid having to do the same work for several different standards.

- Familiarise yourself with the Social & Labor Convergence Program. This initiative helps companies eliminate overlapping audit processes for different standards.

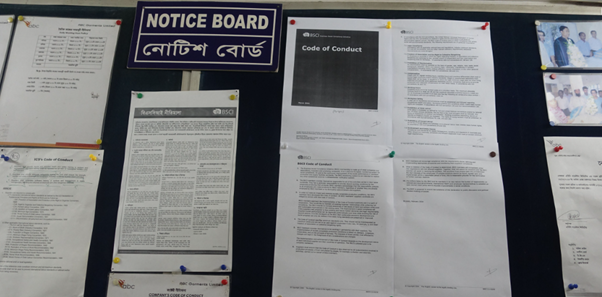

Figure 3: Make your own code of conduct and share it with your employees, suppliers and buyers

Source: Forward in Fashion

7. Familiarise yourself with your buyers’ due diligence obligations

Monitoring responsible production has long been voluntary for European buyers. The OECD’s Guidelines for multinational enterprises were the first multinational effort to encourage companies to behave ethically abroad. After the year 2000, many social compliance initiatives were launched, including ETI, WRAP, SEDEX and BSCI. Starting in 2010, Germany and the Netherlands began working on public-private sector initiatives to convince apparel companies to do their due diligence. Now the EU and national governments are creating laws to ensure that due diligence is conducted.

There are several new European laws to guarantee worker rights and sustainable production processes. Countries that have passed these kinds of laws include the UK (Modern Slavery Act), France (Duty of Vigilance) the Netherlands (Child Labour Due Diligence Act) and Germany (Supply Chain Due Diligence Act). The EU has also implemented several new directives as part of a Green Deal to promote the transition to a sustainable economy. These directives cover corporate sustainability reporting, due diligence and other topics.

The new laws that are being passed make human rights due diligence mandatory for European apparel buyers. This means that companies need to identify, prevent and address human rights violations in their supply chains. Companies that do not comply with these requirements risk legal and reputational consequences. If you want to supply European buyers, you will need to comply with European standards.

Small factories in the apparel sector can take the following steps to comply with social buyer requirements:

- Adopt a code of conduct that describes standards and requirements in relation to health and safety, labour rights and environmental protection. Invest in employee training to ensure that they are aware of these standards and requirements, and to give them the skills and knowledge they need to comply.

- Obtain certification from third-party organisations, such as the Fair Labor Association, to demonstrate compliance with social and environmental standards (see the section on standards below).

- Implement due diligence processes to assess and monitor supplier compliance with your company’s standards and requirements, including through regular audits and assessments. Improve supplier contracts to include clear standards and requirements for health and safety, labour rights and environmental protection.

- Stay in regular contact with buyers to discuss performance, identify areas for improvement and address any concerns.

- Collaborate with other factories, NGOs, governments and industry organisations to improve supply chain practices and address common risks.

Further Reading

The CBI report ‘10 Tips for Finding European Buyers’ can help you find and approach interesting prospects.

The CBI study ‘10 Tips for Doing Business with European Buyers’ provides tips on how to successfully approach potential buyers and develop long-lasting business relationships with them.

This study was carried out on behalf of CBI by Frans Tilstra and Giovanni Beatrice for FT Journalistiek.

Please review our market information disclaimer.

Search

Enter search terms to find market research