How to respond to COVID-19 in the Processed Fruit, Vegetables and Edible Nuts sector

The global outbreak of the COVID-19 virus is having a major impact on international trade. As the market for processed fruits, vegetables and edible nuts may slow down, processors have to adapt. This study provides you with a step-by-step plan. It describes the immediate actions you should take as well as actions that prepare you for doing business in the future.

Contents of this page

- Make the workplace COVID-19 Health & Safety compliant

- Increase social distancing

- Create a crisis team and a communication plan

- Keep staff informed

- Focus on costs and cash

- Develop alternative outbound logistics

- Prepare to diversify suppliers and increase stocks

- Develop products for at-home consumption

- Plan for a recession

- Prepare for pressure on your prices

- Increase productivity and efficiency

- Develop alternative markets and sales channels

Effect on the sector

Many governments have already raised the possibility of recurring lockdowns in response to varying levels of threat around COVID-19. This challenges fruit, vegetable and edible nut processors like you to plan for potential future shutdowns and supply-chain disruptions.

Despite economic stimulus plans, it will take some time before economies rebound to pre-COVID-19 levels. As a result, you also have to plan for a future where demand is somewhat lower, and growth is slower. This uncertainty requires you to find flexible solutions. These will allow you to, first, survive the lockdowns, and then adjust to slower global demand. Critical to this will be getting operational, managing costs, cash flow and operational efficiencies, and developing new outlets for existing and new products.

This study provides you with a step-by-step plan to make that shift - from restarting during the current crisis to stabilising your businesses in the new environment and strategising for what is next.

1. Make the workplace COVID-19 Health & Safety compliant

In most countries, COVID-19 has resulted in suspensions and severe barriers to operating for at least a short period. However, processors of fruit, vegetables and edible nuts have often been allowed to continue or resume operations. Despite some challenges with demand and logistics, this has enabled many of them to maintain some degree of production.

Being able to operate depends on being able to comply with health and safety regulations. The top question every company faces, is how to keep their employees safe and reduce risks as they return to work?

This requires many adjustments from you, including sanitising your premises, providing personal protective equipment (PPE), lowering staff numbers and implementing social distancing measures. To resume production while keeping staff safe, you need to quickly comply with these measures. You also need to stay compliant as new regulations are implemented.

In some companies, all management staff is now working from home. Their offices are used to move production managers off the floor. Shift changes are conducted in smaller groups, and production staff communicates with management via teleconferencing.

Establishing one-way paths and adapting restrooms, lunchrooms and entrances creates distance on the work floor. Where workers cannot keep enough distance, plastic screens can separate workspaces. Other options include only using every third locker in a dressing room or moving part of the production process into an empty storage facility.

Tips:

- Keep up to date with regulations published by your local government authorities.

- Buy the required sanitisation products and PPE and ensure that your employees train to use safe practices. Inform them about the steps they can take to stay safe at work. You can use posters, emails, meetings, videos, etcetera. For more information, see the World Health Organisation's recommendations.

- Reconfigure workspaces to facilitate social distancing.

- Consider creative solutions. For instance, use two-way radios to exchange important information during shift changes.

- Conduct an employee and visitor health screening at the entrance. This means taking their temperature, checking for symptoms, etcetera.

2. Increase social distancing

Social distancing is not only about the workplace. You can separate employees on the work floor. But the risk of infection is still high, if they travel to work in crowded vehicles and stay in cramped worker accommodation where they interact with other companies.

On the other hand, restrictions on movement and closures of public transport have prevented many workers around the world from travelling to work. Public transport systems have been closed, or passenger numbers or hours have been limited. Many processors have had to find alternative means of staff transport to continue operating.

To facilitate social distancing, you should avoid unnecessary travel and identify staff who can work remotely. Typically, this is management staff. As discussed, you can use their offices for employees that do need to be present on site.

You can also increase the distance between workers by reducing the number of workers per shift and increasing the number of shifts. In some companies, fewer people can fit along a sorting belt to increase distance between workers. This means slowing down the processing speed so that staff can still keep up in lower numbers, and expanding operating hours to make up for the reduced speed. Another option is to work 7 days per week to spread out production over more days.

To avoid crowding at entrances, in parking lots and in dressing rooms, you can schedule staggered (spread out) arrival times for your staff. This means employees arrive in smaller groups, for example, every 15 minutes.

Tips:

- Allocate staff to suitable “work-live-travel” groups, by keeping people who live together in the same vehicles and on the same shifts. This can also simplify transport arrangements and provide greater clarity for track and trace systems.

- Make lockdown crisis transport back-up plans. This should include budgeting for increased transport costs, sourcing transport providers and route planning.

- Implement new ways of working to manage remote workers. Use technology to allow management teams to work from home. This can be done by using online communication platforms (like WhatsApp, Zoom and Skype) and online cloud servers to store critical documents. To keep workers motivated, consider creating more visible work plans with planning tools like Trello or Taiga (paid), or open-source free versions like Kanboard.

- Develop staff rotation schedules based on lower staff numbers per shift, existing health conditions, etcetera.

3. Create a crisis team and a communication plan

There is no denying that these are stressful times. The various restrictions on trade have created great uncertainty for clients, suppliers and staff. Having good crisis communication skills is essential in this challenging time.

To plan for crisis management, you should agree on a small cross-functional crisis team to manage communication during the crisis. This typically includes representatives from production, sales and communications and logistics. The crisis team needs to create a crisis communication plan to determine how to tackle communication. For this, the team needs to get a clear understanding of the situation with operations and how this will affect customers, as well as existing and new orders.

Communicating clearly and proactively with customers during this crisis is particularly important. Keep customers up to date with the changing situation in your country and your production facility. Let them know how this affects service level agreements. While a simple direct email is essential, there are additional ways to build relationships and stand out. You could consider a COVID-19 newsletter, dedicated pages on your company website, Frequently Asked Questions (FAQs) around your response, LinkedIn updates or even Facebook videos.

In general, good communication in crisis management can protect your relationships with customers. In some cases, relationships can even be made stronger. But managing communications should extend beyond customers. Consider suppliers, business partners, government stakeholders, investors, etcetera.

Tips:

- Create a regular meeting schedule for your crisis team throughout the crisis.

- Communicate early and often. Make sure you keep customers up to date with the situation as it evolves. You communicate about the impact on their business and how this will affect your agreed terms of doing business. Communicate delays, what solutions you are putting in place and expected delivery dates. Do not speculate. Be clear about what you know and what you do not know yet.

- Make communicating a two-way street. Reach out to priority clients personally. Try to understand their situation and the impact that COVID-19 is having on their business. Assess whether you are able to help or can point them to potential solutions to their challenges.

- Include key elements in your crisis communication plan: who develops the communication, how you will communicate, who will be the key point of contact and who needs various pieces of information. Consider developing mailing lists to ensure that this goes smoothly in the crisis.

4. Keep staff informed

This is a challenging time for staff, many of whom are essential to resuming operations. Keeping the lines of communication open can be the difference between effectively managing your workforce and having staff walk out or having a work stoppage to deal with.

You may need to make difficult decisions. Keeping your staff well-informed might make it easier to communicate difficult decisions and solve tough problems later on. This is because it allows them to understand the intent behind these choices and why it is necessary, as well as how the business will now be operating and what is expected of them.

To organise this, you can create an internal communication plan that clarifies how staff will be informed of news and updates as the situation changes. The plan should identify key messages and talking points, a reliable method for ensuring that each staff member is kept up to date, and a method for collecting feedback from staff. Will you use team meetings, line manager phone calls to each staff member, flyers/posters or other means of communication?

Tips:

- Reassure the workforce that your organisation is aware of the situation and is taking relevant precautions. Point staff towards official guidance, for example from the World Health Organisation.

- Summarise company policies. Make sure that your staff understands the changes to health plans, attendance requirements, time off and payroll arrangements, work from home policies, etcetera. Clearly articulate procedures and expectations that employees should follow.

- Name a key point of contact for questions from employees.

- Provide resources to keep them engaged and feeling motivated. For example, Jupiter Group has published an online wellness session with a personal trainer.

5. Focus on costs and cash

When sales fall, there is no incoming cash to fund operations. On the production side, measures to meet COVID-19 regulations cost money and raise expenditure. If you cannot slow down expenditures at the same or a similar speed, your cash reserves and eventually your credit get used up. Cash management has never been as important as now. You need to tightly manage cash inflows and cash flows, to prevent your business from becoming insolvent. This requires you to be both proactive and realistic.

You must reduce the amount of cash leaving your business. Wherever possible, renegotiate payment terms with suppliers, ask for deferrals of payments and freeze flexible spending such as training programmes, non-essential travel and staff welfare costs. You also need to reduce your wage bill. Although reducing staff days and hours is never a pleasant step, it may be a necessity in the weeks and months ahead. You can ask staff members to take paid or unpaid holiday leave when they are not on rotation or defer salaries of management staff.

To keep cash coming in, you should chase outstanding payments. Contact your debtors to discuss if and when they are able to pay. You should also explore emergency financial support programmes from government, banks and sector organisations. It often pays to get expert help from accountants who specialise in these services, so you can focus on other aspects of your business.

Tips:

- Identify the main contributors to your costs and target these first for reductions.

- Consider restructures and staff retrenchments to adapt to decreased demand. Work with experts to ensure you remain compliant with existing legislation and emergency measures.

- Follow up with your debtors quickly to get cash in as soon as possible. Make arrangements that may include rescheduling payments or writing off debt.

- Consider incentives for quick payment. For example, offer your debtors a 5%-discount for paying within 2 weeks instead of 4 weeks.

- Consult experts in the area of financial support programmes. Getting government support can be complicated and time-consuming at any time. But it is even more difficult now that government departments have to process large numbers of grant applications and financial transactions. You need specialists who know how to track and unblock an application.

6. Develop alternative outbound logistics

Logistics have been heavily affected by the lockdowns. Many borders have been closed, new safety regulations have increased the times needed for border clearance and port handling – if movement has been possible at all. Most countries have also restricted or stopped international flights, which has shrunk the air freight capacity. As a result, shipping containers have been stuck at ports and transit points at state borders. In some countries, only essential goods have been allowed to travel.

For many processors, this has meant extreme pressure on outbound logistics. Finding alternative solutions is critical to resuming operations and delivering against existing service level agreements.

In some markets, processors have worked together to book charter flights. For example, fresh cut fruit producers in West Africa have worked with fresh exporters to charter flights to Europe. This is more costly, but it also ensures that exporters can deliver promised orders and create some income. KLM’s KickCharter programme combines shipments for multiple suppliers. It only flies if there is enough demand, so coordinating with other processors can help to speed up delivery.

Tips:

- See ColeaCP's overview of changing logistics from Africa and Maersk’s operational status tool to get a sense of changing shipping conditions.

- Work together with other companies to arrange for the delivery of shipping containers.

- Reconsider your business model. Does it make sense to rely on passenger aircrafts to transport fruit? Can you find innovative ways to use sea freight? For example, by shifting to reefer containers, packaging under nitrogen, etcetera?

7. Prepare to diversify suppliers and increase stocks

Logistics and the production of ingredients for processors have been disrupted around the world. In some cases, this has made it difficult to obtain raw materials. Sometimes containers are not available, there is port congestion or lower frequency of boats and trucks. And sometimes factories or farms have not been able to operate due to lockdowns or outbreaks. Because the pandemic develops at different speeds around the world and will probably flare up again, this situation is likely to remain. This has led, and may continue to lead, to production being halted due to lack of raw material.

Importers and processors around the world have reacted by focusing on their core products. This is because their clients demand them. They have also been keeping larger stocks of essential products and are looking for additional suppliers to spread risk. This can also be an opportunity for you to find new clients. At the same time, you also need to make sure you keep enough stock of ingredients and diversify your supply base for ingredients where you rely on a single source.

Tips:

- Identify key ingredients, inputs and machine spares, and increase your stock levels.

- Increase your stock levels of core product lines to ensure that you can accommodate orders despite lower production and production stoppages.

- Evaluate your storage capacity and make arrangements for additional storage on- or off-site. You might need increased security.

- Look for importers who are vulnerable because they rely on important raw materials from a single country or region. For example, COVID-19 has interrupted major shipments of coconut water to Europe. Can you fill this gap, or compete to become an alternative supplier from another region?

- Identify additional suppliers and negotiate deals in advance of future lockdowns.

- Approach fresh fruit packhouses to investigate if you can source their products for processing. Many fresh producers are dealing with interrupted harvests or declined demand.

8. Develop products for at-home consumption

Many countries have introduced restrictions on hotels, restaurants, large events and fairs. As a result, demand for products that are usually consumed “out of home” has come to a halt. This has left many suppliers to hotels, restaurants, airlines, work canteens, etcetera (the HoReCa) with dramatic declines in orders.

Instead, there has been a major shift in where people eat and source their food and the product formats that they buy. For example, where you previously might have eaten a pizza prepared at a work canteen, you now might prepare your pizza at home using a pre-prepared pizza base. The vegetables required for that pizza are now sourced from a retailer, rather than from a wholesaler for the HoReCa trade. In the fruit juice sector, people now might prefer litre-boxes of juice rather than smoothies that are typically consumed on the go.

Overall demand for processed fruit, vegetables and edible nuts may stay more or less the same. However, how they are distributed and in which formats they are sold might be very different. The best scenario for processors would be to switch production towards products and sales channels that cater to at-home consumption.

Tips:

- Identify the product lines most vulnerable during lockdowns. This particularly applies to pack sizes for the HoReCa and on the go consumption. Reduce your stocks of these.

- Create a plan for shifting production to at-home pack formats. This might involve prioritising the production of existing products in your portfolio towards products that are distributed to retailers. Or you could introduce new pack types that cater to families, such as family pack sizes and multipacks.

- Build relationships with contract packers and packaging suppliers to be able to quickly switch production to new formats.

- If you are able to use a contract-packer or distribute traditional HoReCa products for at-home consumption, link up with these companies and put in place production plans that can be turned on if needed.

9. Plan for a recession

At some stage in the coming months, we will reach a new state of normal. In many European countries, governments are allowing restaurants, bars and workplaces to (re)open. However, this is probably not enough to cover lost sales during the lockdowns. Higher unemployment levels and lost incomes are now predicted to result in an economic recession that will last several months, or even years.

Demand for food tends to be to fairly stable overall during recessions. But consumers often change what they buy and where they consume these products. Previous recessions have shown that consumers switch their spend to value-for-money products. For example, where they might have bought a premium smoothie before the recession, they now might buy a more affordable pear juice.

On the other hand, others might look for affordable luxuries to replace eating out of home. Small treats, once considered unnecessary or even expensive, now seem affordable and well-deserved. As a result, sales of premium sorbets, quality refrigerated desserts and pre-prepared meals all tend to grow during recessions. This will also affect processors, and present you with both challenges and opportunities.

Tips:

- Market existing products in your product portfolio that are value offers, such as dried-fruit rolls.

- Consider whether you can convert waste into new affordable value products, such as fruit snippets rather than mango cheeks, leathers or bars.

- Consider using lower-cost ingredients to create more affordable products, for example by blending peanuts with macadamias.

- Consider how products with built-up stocks could become a part of a new value offer, such as blended A- & B-grade nuts or mixed frozen vegetable packs with premium and low-cost vegetable blends.

- Determine which of your products could become affordable luxuries and market these as such. Examples are chocolate-dipped dried fruit, premium cut mango chunks, dried fruit in juice cups, fruit sorbets, vegetable pizza bases or wraps, luxury salad ingredients, luxury exotic smoothie blends and restaurant-quality ready-made meals.

- Partner with HoReCa distributors to distribute your products directly to the consumer together.

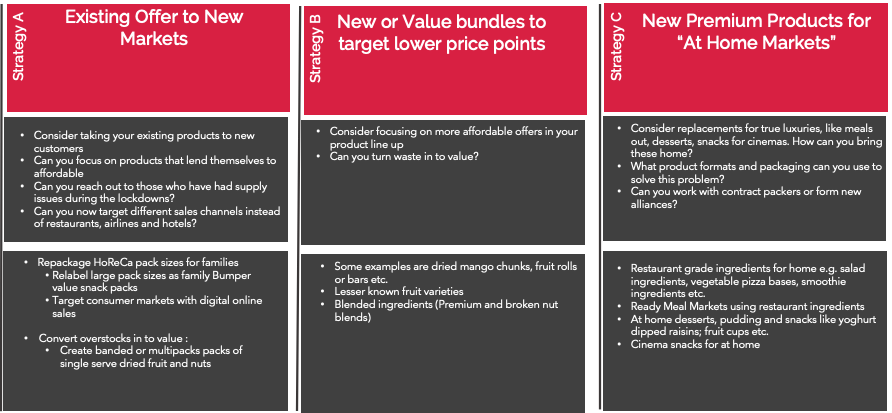

Table 1: Potential strategies to plan for a recession

10. Prepare for pressure on your prices

During recessions, many retailers focus on keeping or winning customers by maintaining or even cutting prices. This has an impact throughout the entire supply chain. Manufacturers face significant pressure to avoid or delay prices increases for as long as possible. Importers and manufacturers actively look for lower prices from existing suppliers, or for new suppliers who can provide the same products cheaper.

You need to develop a clear pricing strategy and prepare well for price-increase discussions with your customers. This might even offer opportunities to find new customers.

Tips:

- Prepare for delays in implementing price increases. This is because buyers are often unable to accept price increases in your set time period. You might need to agree to some delays to maintain good working relationships with key customers. Start early to ensure that you have the time to smooth out issues and can implement your price increase in line with your budget.

- Determine how long you can delay a price increase. Will you wait for your competitors to increase their prices first? Or will low cash reserves mean that you need to increase yours earlier?

- Develop a nuanced strategy across your product range. Could value offers have smaller price increases than premium products?

- Communicate price increases sensitively but clearly with your customers. For examples of price increase letters, see how to let customers know about a price increase (without making them mad).

- Budget for price discounting, in case you begin to lose orders.

- Explore whether there are opportunities to market discounted products more widely. Remember to set realistic expectations. Are you offering overstocks of top-quality products for less? Or is this a true “value offer” where you offer a little less for a lower price? Remember that the prices and expectations you set now affect the prices you will be able to achieve in the coming seasons.

11. Increase productivity and efficiency

Most processors can expect to need to produce with lower staff numbers per shift for some time. At the same time, there is pressure to contain costs. As a result, you will need to become better at doing more with less. This is a moment where many will need to look at how they increase the productivity of their staff and general efficiency in the production facility.

Tips:

- Upskill staff so that they are more efficient and can be multi-skilled. This allows for more flexible allocation of staffing in various staff rotations.

- Consider automation of some parts of your operations.

- Consider contract packing to fill excess capacity and decrease downtime.

- Review your production process and address bottlenecks, slow speeds, etcetera.

- Repair or upgrade machinery to increase line speeds and decrease downtimes.

- Increase the number of shifts worked per day, to reduce staff numbers per shift.

12. Develop alternative markets and sales channels

Perhaps your business has already been hit by declining demand. Or you would like to protect your business from the negative effects of COVID-19 in the coming months. To create more resilience in their business, you could develop new sales and distributions channels, target new customers or bring new products to market.

Tips:

- Consider whether you need to engage agents in end markets to find new clients, now that intercontinental travel will become more costly and difficult.

- Develop digital marketing materials for new customers, including a good overview of your products, your certifications, etcetera. However, giving them a sense of your operations is particularly important now they cannot visit you. Share high-quality photographs and videos of your production facilities. These examples for frozen fruit, dried fruit and fresh-cut salads have very high production values. However, this is not always needed. An impression of your production facility is often enough at the start, so keep it simple but clear.

- Attend trade fairs and industry association events to network and meet new clients. Some have gone digital.

- Make sure that you have a modern website that attracts potential clients.

- Lobby your local chambers of commerce and chambers of commerce in European markets for virtual sourcing and buying missions. Work with import promotions desks and European chambers of commerce to market your products.

Examples of digital marketing in processed fruit, vegetables and edible nuts:

CEA Farms is a Colombian concentrate and fresh producer has set themselves up for success with:

- a website that is professional and easy to navigate

- material that is available in both English and Spanish

- a clear product list with downloadable product specifications

- a clear list of certifications

- video and photography that shows potential customers their operation from farm to port. This includes products, staff, machinery, logistics, equipment, etcetera.

- a clear Unique Selling Point (USP), well-articulated benefits and reasons to believe

- a site that has beautiful visuals and engaging text

- contact details that are easy to find

TecoFoods is a frozen fruit producer from Poland. They have a simple website that quickly gives visitors a sense of their business, via:

- a snapshot of the company that acts as an elevator pitch

- beautifully illustrated visuals

- reasons to believe their professionalism (customers, equipment, certification)

- clear contact details

Blue skies is a fruit processor with production facilities in Ghana, South Africa, Egypt and Brazil. They produce freshly prepared fruit, juice and sorbets. Their digital marketing is well rounded and very professional. They have:

- a well branded, polished website that is easy to navigate

- a clearly communicated sustainability story, which is a big part of their USP

- useful information about the products they sell

- a real sense of the company, its values and their level of professionalism

- contact details that are easy to access

- regular news, which keeps them in touch with their customers

- a good presence on social media (Facebook, YouTube and Instagram), but especially on LinkedIn where importers are found[CM1]

This study was carried out on behalf of CBI by Michiel Arnoldus and Kerry Kyd of Time for Sense.

Please review our market information disclaimer.

Search

Enter search terms to find market research