7 tips on how to go green in the processed fruit and vegetables and edible nuts sector

Becoming greener and having a more climate-positive impact can bring many benefits to exporters of processed fruit and vegetables and edible nuts to Europe, in terms of market access, consumer demand, reputation and sustainable development. If you demonstrate that your products have a positive climate impact, you may have a competitive market advantage. This can help build trust, loyalty and long-term relationships with customers, suppliers and other stakeholders.

Contents of this page

- Identify specific environmental risks in your sourcing, processing and export

- Turn environmental challenges into opportunities by reducing your environmental impact

- Measure the carbon footprint of your production for the whole supply chain

- Monitor green innovations for inspiration on reducing your environmental impact

- Comply with the green legislative requirements to be competitive on the European market

- Incorporate green principles in your code of conduct

- Find funds, investors and partners that can help you become greener

1. Identify specific environmental risks in your sourcing, processing and export

To become more environmentally friendly/aware, you must first identify the specific environmental impact of your company. One of the most common mistakes in this process is to focus only on your processing operations. For a complete environmental assessment in the fruit, vegetable and nut processing sector, you should identify the total environment impact of your supply chain. In practice, this means identifying the impact related to:

- Sourcing of raw materials (agricultural practices);

- Ingredients;

- Packaging materials;

- Processing operations;

- Local and international levels.

Environmental impact cannot be generalised for the entire fruit, vegetable and nut processing industry. For example, it is often assumed that along the supply chain in this sector, agriculture contributes the most to greenhouse gas (GHG) emissions. This claim may be relevant for the intensive use of mineral fertilisers, but in many developing countries fruit and nuts are grown almost without any fertilisers or irrigation.

Agricultural practices

Intensive agricultural operations can harm the environment through fertilisation, irrigation, machinery and plant protection chemicals. In addition to these main factors, organic waste is often burned directly in the fields, polluting the air. This organic waste includes branches cut by pruning, husks from nuts, removed weed or inedible parts of fruits or vegetables. According to FAO data, the largest equivalent carbon dioxide emissions from burning crop residues are released in China (6,600 kilotons), followed by the United States, France and Italy.

When assessing environmental risks related to the agricultural practices of your fruit, vegetables or nuts suppliers, you should probably start by estimating the used nitrogen fertilisers. In fruit and vegetable growing, nitrous oxide emitted from synthetic fertilisers and manure is responsible for most of the total agricultural greenhouse gas emissions. Along with fertilisers, you should also estimate the emissions from the agricultural machinery used.

As the next step, you can identify water consumption through irrigation practices. Intensive irrigation can lead to water scarcity, putting production at risk. Last, you can estimate the frequency and quantity of pesticide applications. If not used or discarded properly, pesticides easily contaminate the air, soil and water. Also, they can harm biodiversity by killing other animals instead of only pests (bees, birds, worms, etc.).

One example of water scarcity risk is the case of pistachio production in Rafsanjan (Iran). More than 95% of water in this region is used to irrigate pistachio orchards. Intensive use of water has led to an increase in well depths. In the last 30 years, the average depth of wells has gone from 20 m to over 300 m. Today, Rafsanjan faces a severe water scarcity and pistachio production is decreasing.

Energy consumption

In your impact assessment, you should first identify the amount of energy consumed expressed in kWh or in MJ for your operations. It is equally important to identify the share of renewable energy. One of the mistakes people make is to assume that only fossil fuels are polluting and that electricity is 'green' energy. Only electricity produced from renewable sources (water, sun, wind) can be called 'green'.

See the table below to learn more about energy consumption hotspots per subsector.

Table 1: Energy consumption hotspots in the processed fruit, vegetables and edible nuts industry

| Sector | Explanation |

| Frozen fruit and vegetables | To freeze 1 kg of fruits or vegetables, 2-3 kWh of energy is usually needed. Initially this may seem like low energy consumption, but frozen products are often kept in deep-freezing warehouses for months before export. Storage time can significantly increase energy consumption. |

| Processed juices | Most energy is consumed by vacuum evaporators for concentrating juices and pasteurisation. Reducing transport costs can compensate for the energy used for juice concentration. Transporting concentrated juices is more energy-efficient because of the reduced volume. |

| Canned fruit and vegetables | Heating operations consume the most energy in this sector. Prior to filling, empty cans are commonly sterilised with hot steam. Also, products are often blanched. Last, heat sterilisation is used to sterilise closed cans. |

| Dried fruit | Hot air is commonly produced by burning gas or sometimes organic materials (such as wood). To increase storage time, fruit can be initially dehydrated to low moisture values (e.g. less than 20%) and in some cases partially rehydrated before packaging and export. This rehydration process consumes additional energy. |

| Edible nuts | Energy is used for drying of in-shell nuts before cracking. Also, heat sterilisation is increasingly used. Processing of cashew nuts is one of the most energy-demanding operations, as it additionally requires steaming before cracking. According to study on energy consumption of small-scale cashew processors in India, the energy required to process 1 tonne of raw cashew nuts to kernels is around 6000 MJ. |

| Jams | Energy is mostly consumed in evaporators for jam cooking. Although this is an energy-intensive process, jams can be stored for a long time without temperature control. |

Water consumption and wastewater generation

Water is used for washing raw materials, heating, blanching, pasteurisation, and disinfection of facilities and equipment. Water can also be a part of the final products such as canned fruit and vegetables, table olives or nectars. According to a 2020 study by amfori (PDF), the wastewater generated by smaller canning facilities is comparable to that of a population of 20,000, whereas large facilities can generate an amount comparable to a population of 250,000.

Wastewater from fruit, vegetable and nut processing companies is often discharged into rivers or seas. This can lower oxygen levels, killing fish and other aquatic animals.

One subsector that generates significant quantities of wastewater is olive oil processing. Wastewater generated by olive mills contains high concentrations of organic compounds (mostly phenols), which can contaminate the soil and water.

Detoxification solutions are usually too expensive for North African and Middle East processors, so it is common to dispose of wastewater into rivers and lakes or use it for farming irrigation.

Air pollution

Air pollution in the fruit and vegetable processing industry depends on the type of fuel used to run processing equipment. Fruit drying still uses burning gas or wood to produce heat, even though it generates carbon gas emissions. In the subsector of frozen fruit and vegetables, one major risk is leakage of ammonia gas from refrigeration units. Ammonia is very harmful to the eyes and the respiratory tract, and contaminates the soil and groundwater.

Deforestation

Production processes in the sector of processed fruit and vegetables can affect biodiversity negatively. Intensive agriculture can lead to deforestation or destruction of native biodiversity (as is the case with palm oil production). Overharvesting of wild collected products (e.g. Brazil nuts in Bolivia and Brazil, pine nuts in China) can lead to the collapse of entire ecosystems.

Figure 1: Deforestation of land for palm oil plantation in Indonesia

Source: Flickr by glennhurowitz, licensed under CC BY-ND 2.0

Packaging

The type of packaging is also part of your environmental impact. The best packaging options are made from renewable materials. If the material used is not renewable, then you should aim for reusable or recyclable materials. However, industrial practices and current packaging solutions are not always sufficient to minimise environmental impact. The most common export packaging solutions in this sector are:

- Lower environmental impact (renewable materials): Jute bags or linen fabric bags (for in-shell nuts), carton boxes (outer layer for dried fruit, frozen products and nut kernels packaging);

- Lower-middle environmental impact (reusable and recyclable materials): Glass bottles (retail packed juices), glass jars (jams). However, glass is not often used as export packaging;

- Upper-middle environmental impact (synthetic recyclable materials): Plastic liners (contact material for dried fruit, frozen fruit and vegetables), plastic bags (nuts, frozen products), plastic barrels (olives, olive oil, pickled vegetables). In many countries the percentage of recycled plastic is still very low and the litter in natural areas/oceans is at a record high;

- Higher environmental impact (not renewable but recyclable): Tin and aluminium cans (canned fruit and vegetables), aluminium bags (nuts), bag in a drum (juices and purees). Still, there is a big carbon emission difference between producing countries. For example, the production of 1 tonne of aluminium in China emits 20 tonnes of carbon dioxide on average, which is almost three times more compared to the aluminium produced in Europe.

Transport

Transport is one of the most important sources of carbon emissions for non-European suppliers of food to Europe. The transport of processed fruit and vegetables from non-European countries can contribute to up to one-third of the total product-related carbon emissions. However, export transport gas emissions are usually out of the control of the processing companies. This is the case because transport is usually sub-contracted, and the environmental impact depends on the chosen mode of transport and the shipping company.

Tip:

- Advise farmers to cover the manure with a layer of surface soil immediately or within 12 hours of bringing it to the field at the latest. In this way, they will preserve the nitrogen for plants and the carbon dioxide emissions will be five times lower compared to manure left on ground.

2. Turn environmental challenges into opportunities by reducing your environmental impact

After you have identified the highest risks along your supply chain, you should measure your environmental impact. This is measured in specific units, such as the amount of generated waste, used water, and consumed energy or carbon emissions. By measuring the impact, you can set the aim of reducing it. After setting your goals and implementing measures, you can communicate them in your reports and your website, and directly to the buyers.

Some possible solutions can be roughly grouped in six broad categories: agricultural practices, water management, energy efficiency, use of renewable energy, use of by-products, and sustainable packaging and transport.

Sustainable agricultural practices

Intensive growing of fruits, vegetables and nuts can be risky for the quality of the soil, water, air and biodiversity. It is therefore very important for each processor to communicate with farmers and to support sustainable agricultural practices. In this way you will ensure a sufficient and long-term supply of raw materials for your own production. The most common ways to preserve soil, water and biodiversity are:

- Consider using cultivars that are resistant to most common pests and diseases: in this way farmers can reduce production costs, as they will use less pesticides. Some cultivars can also provide a higher yield without increased water usage;

- Implement integrated pest management – With the use of agricultural forecasting services it is possible to monitor the development of insects and to use insecticides timely and in much smaller quantities;

- Use regenerative agriculture practices – The most common regenerative agriculture modality is organic agriculture. In addition to having environmental benefits, organic certification also ensures higher prices for farmers and processors;

- Use fertilisation smartly – Soils can be preserved through the better use of manure, while mineral fertilisers can be precisely applied according to soil analysis;

- Use branches of fruits and nuts cut during pruning for mulching (preservation of soil moisture and protection from weed);

- Save water through good water management practices – Drip irrigation uses significantly less water compared to flood irrigation. Smart irrigation based on sensors that measure soil moisture and specific plant needs can reduce water usage by 50% without affecting the yield. If rainwater is collected and used for irrigation, the water savings can be even higher;

- Enhance biodiversity – Bees (and other insects) can be used for pollination and to increase the yields. Bird columns can be used to increase the number of bird-eating pests. The top priority should be to always insist on deforestation-free products when sourcing your raw materials.

There are many good green practices in developing countries. For example, the Fruit Fly Control Project in West Africa has managed to decrease mango damage by fruit flies by 57% with a unique surveillance system. This system uses natural parasites (wasps) and predators (ants) that attack fruit flies. Another example is the Tunisian company South Organic, which uses nets to protect dates from insect damage.

Water management inside processing facilities

Water use by the fruit and vegetable processing industry is essential for the washing, heating and cooling of food products. The use of water in processing facilities can be reduced through more efficient operations, recycling and re-using wastewater, and opting for alternative water resources. Some ideas for better water usage:

- Install low-volume, high-pressure spray cleaning systems;

- Collect water removed from fruits and vegetables during drying or during juice concentration;

- Use air cooling after blanching instead of water cooling;

- Collect and use water used for washing fruits, vegetables and nuts by installing cleaning and filtering equipment;

- Collect rainwater.

Improving energy efficiency

Energy efficiency in freezing and cooling operations can be significantly improved with better refrigerants and cooling systems. For example, the R134a refrigerant with variable frequency drive chillers can reduce electricity consumption by up to 55% compared with a system that uses ammonia. This also leads to a significant reduction of greenhouse gas emissions.

Energy efficiency in the juice industry can also be improved by using enzymes for juice extraction. With the use of enzymes, around 5% less fresh fruit or vegetables is needed to obtain the same amount of juice. This also saves around 3.4 kg of carbon dioxide emitted per tonne of concentrated juice. Another energy-saving solution in the juice industry is to use membrane evaporation, which is a more energy-efficient option for water removal than steam-based evaporation methods.

One of the solutions to decrease energy consumption in heating is to use innovative technologies. One such technology is called Pulsed Electric Field (PEF), which uses lower heating temperatures. PEF technology is relatively new but is already being used by the juice industry in several countries. It can be also used in the drying of fruit. The European project Food Processing in a Box has already supported the development of small-scale juice-processing units with PEF technology.

The general improvement of energy efficiency in all processing operations is better insulation of walls, roofs, pipes, sterilisation machines, heat exchangers and so forth.

Finally, it is important to mention that energy efficiency can be improved by using renewable energy. A common example in fruit and nut drying operations is to use pits from fruit or shells from nuts to heat boilers.

Use of by-products

Different processing operations provide opportunities for a circular economy. Several examples of by-products from the sector are listed below:

- Shells (in the nut processing industry) or pits (in the dried fruit industry) to heat boilers and generate energy for drying;

- Inferior-quality products like animal feed;

- Pits of fruits after peeling for the production of starch or bioethanol;

- Peels of fruits and vegetables before processing for the production of pectin, colorants, fibres, etc.;

- Low-grade nuts for the production of high-quality oil;

- Cashew apples and many other fruits to produce jams, juice or for compost;

- Olive-processing waste to extract polyphenols for the food supplement and cosmetics industries. Same for grape seeds, avocado seeds and other stones/seeds.

Figure 2: Use of shells for heating the boiler in the macadamia processing industry in Kenya

Source: Autentika Global

A good example of environmentally friendly practices is the Kenyan company Afrimac. During macadamia processing, the shells are removed and re-used to heat the boilers. This is a common practice in the Kenyan macadamia industry. Afrimac additionally introduced the use of solar energy in their processing plants. In fact, 70% of the energy used to run machines comes from the sun. In this way, the company saves 3.3 tonnes of carbon dioxide emissions annually.

Decreasing carbon emissions during transportation

The highest carbon emissions in the fruit and vegetable processing sector are usually related to the transport of fresh products to the processing facilities. In many cases, small trucks (running on diesel fuel) are used to transport products from farms to facilities. The global warming potential of diesel fuel is over 20 times that of carbon dioxide. One option to reduce emissions is to support your suppliers in using biodiesel and renewable diesel.

Carbon emissions are also related to export shipment. Whenever possible, you should choose ocean freight shipping as this is currently the most emissions-friendly mode of transport. Sea fright emits 7g of carbon dioxide per km, which is significantly lower compared to rail (24g), road (137g) or air (654g).

Although sea shipping is subcontracted, it is possible to decrease its environmental impact by choosing a shipping company with a low Carbon Intensity Indicator (CII) rating. According to CII regulations, each vessel needs a rating of C or higher. Also, you can ask your shipping company to provide the estimated carbon dioxide emission for each shipment, as this can also depend on shipping speed. For example, increasing the shipping time from China to Europe by two to three days can reduce carbon emissions by more than 30%.

Tips:

- Read the Energy Efficiency and Cost Savings Guide for the Fruit and Vegetable Processing Industry (PDF) to find energy-saving solutions for your type of processing.

- Use the seaxplorer tool (registration required) to search for the best way to save carbon emissions related to your shipment.

3. Measure the carbon footprint of your production for the whole supply chain

Companies in Europe increasingly use labels related to carbon emissions to promote products as environmentally friendly. Those labels use a variety of terms that can confuse consumers, such as 'carbon neutral', 'zero carbon', 'carbon negative', 'net zero CO2'. Some of those labels are not based on solid scientific environmental footprint methods. When promoting your environmental impact, make sure you are using the relevant measuring criteria.

GHG emissions are typically measured and reported in a carbon dioxide (CO2) equivalent. Besides CO2, there are other common gasses emitted from agricultural production, like nitrogen released from nitrogen fertiliser applications and methane from rice production. Gas emissions are multiplied by their Global Warming Potential (GWP) to convert them to the CO2 equivalent. The GWP shows that nitrogen has a greater impact on global warming than carbon dioxide per unit mass.

According to the European Association of Fruit and Vegetable Processors, the average carbon dioxide emission for processed vegetables is approximately 0.7kg carbon dioxide emissions per kg. However, you should not use general industry estimations but make your own calculations.

To lower negative environmental impact, companies in the processed fruit and vegetables and edible nuts sector are advised to calculate the current consumption of resources.

After a careful analysis it is important to make a cost-benefit analysis of the options that should lead to a lower impact and to select the most beneficial solutions.

Table 2: Some criteria for assessing the environmental impact of fruit, vegetable and nut processors

| Criteria | Type and units | Some points of attention |

| Mass balance – a difference in the quantity of raw materials (fruit, vegetables or in-shell nuts) and the quantity of final products | Kg | Can by-products/waste be reused? Can better equipment produce larger quantities of final product? |

| Energy consumption | L diesel m3 natural gas steam kWh | Can energy from fossil fuels be, at least partially, substituted with 'green' energy? Can available energy be used more efficiently? |

| Water consumption | m3 | Can water be recycled/reused? Can steam and evaporated water from fruit be reused? |

| Waste | kg | Can waste be recycled? Can the amount of waste be lowered? Can you shorten distance to the point of waste disposal? |

| Raw materials | CO2 emission per kg produced fruit, vegetables, nuts | Can you make average assessments in communication with your suppliers/farmers? |

| Ingredients | CO2 emission and production method | Can your ingredients be purchased from nearer? Can ingredients be produced as organic? |

| Processing aids | CO2 emission and type | Can producers estimate environmental impact to produce the processing aids? |

| Packaging materials | Kg, energy consumption CO2 footprint per kg/piece | Can you estimate CO2 emissions to produce one unit of packaging? Can you shorten the distance of purchasing packaging materials? Can you purchase sustainably certified packaging materials? Are packaging materials recyclable or biodegradable? Can pallets be reused or recycled? |

| Transport | CO2 emission per km Type of fuel used | Can you use sea fright? Can you use a transportation service that measures CO2 emissions and can offer best routes to reduce CO2 footprint? |

It is important to estimate the environmental footprint before and after processing: before processing, the environmental footprint relates to agricultural operations, after processing it relates to transport, further processing and retail operations.

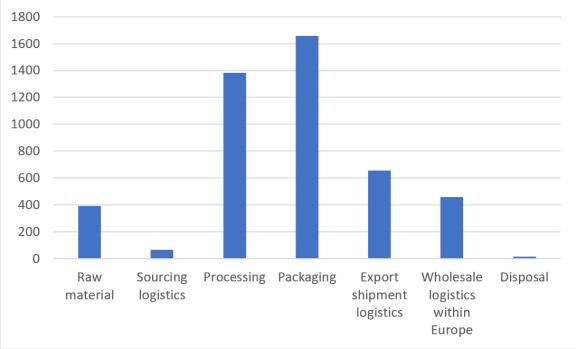

Figure 3: Example of the environmental footprint of canned pineapples, for 1000 cans, CO2e/kg

Source: Henry Lamotte Food, adapted by Autentika Global

Henry Lamotte Food advice for SMEs when calculating carbon emissions

- Try to be as specific as possible. That means gathering primary data that stems from your supply chain. Quality data on scope-3 emissions are valuable to other stakeholders downstream in the value chain, especially retailers who want to communicate their product carbon footprints to their consumers.

- Be prepared to make compromises. Making use of secondary data whenever it is impossible to gather primary data is legitimate if stated explicitly.

- Be aware of the shortcomings of the calculations. E.g. lack of (or missing) data, the static nature of a one-time calculation, calculations should always be perceived as estimates only, etc.

- Work with trusted consulting companies. Get help with the calculation whenever possible. The calculation should conform with a common standard like the GHG Protocol. External expertise is helpful, especially for SMEs where resources are at times limited. If the expertise of the consulting partner is to be trusted, this should also lend more credibility to the calculation. Having a third party verify your calculations would be the icing on the cake.

Calculation is only the first step. Adding value to mitigating the effects of the climate crisis begins with knowing our impact on the climate. The goal of calculating our carbon emissions should always be accompanied by measures to reduce them wherever possible, especially within our sphere of influence.

Tips:

- Book demonstration for a tool to calculate gas emissions for food companies to see the practical applications for your company (developed by Olam). The same company also developed the sustainable sourcing platform AtSource, which includes an environmental footprint calculator.

- Follow the Agriculture Guidance Protocol to measure specific greenhouse gas emissions for fresh fruit, vegetables and nuts before they reach your processing facility. Along with this global guidance, there is a specific guidance developed for Ethiopia and Brazil.

- Watch Greenhouse Gas Protocol training free of charge to estimate your company’s greenhouse gas emissions.

- Use some of the available databases, like CarbonCloud or FoodFootprint, as a starting point to calculate your environmental impact. At present, the most complete and free-of-charge database containing environmental impact data may be the French Agribalise database. If you want to consider commercial tools, HowGood is a good example, specifically developed for food companies.

4. Monitor green innovations for inspiration on reducing your environmental impact

There are many emerging technologies that can improve the efficient use of resources in the fruit, vegetable and nut processing industry. Many of them can provide energy and water savings while boosting productivity and water quality. Figure 4 below presents a comparison of different processing technologies based on the work of Italian scientists in the juice processing industry. Some of these innovative technologies are already being used in fruit processing, so you can explore them in detail by contacting the companies that use them.

Source: Springer Link (study by Giuseppe Vignali, Mario Gozzi, Massimiliano Pelacci & Roberta Stefanini), graph adapted by Autentika Global

It is important to select green innovations based on real industry experience. For example, it is easy to conclude that non-thermal approaches are most energy-efficient. However, some innovative technologies (like pressure change or pulsed light radiations) are still in the testing phase and not yet used by industrial food processors. Sometimes energy savings can be achieved with the existing technology but also with equipment adjustments. A good example is the continuous nut roaster, which saves up to four times more energy than other roasters.

Along with improving energy efficiency and water management, many innovations relevant to the sector involve the utilisation of by-products. The range of solutions is wide. Some interesting examples include new bioplastic packaging material made of olive oil waste and the use of orange peel in lamp designs.

Tips:

- Search the Solarimpulse Foundation’s solutions to fight climate change database to find green inspiration relevant for your production. Click on 'Food and Agriculture', then filter results 'by application' according to your interest.

- Check the best practices toolkit of the EU-funded SwitchMed initiative to find innovative solutions for saving water, energy and materials. Under 'sector', select food and beverages, then under 'subsector' select 'Processing and preserving of fruit and vegetables'.

- Check the Africa Innovation Platform to cooperate on innovative solutions for green production and processing practices.

5. Comply with the green legislative requirements to be competitive on the European market

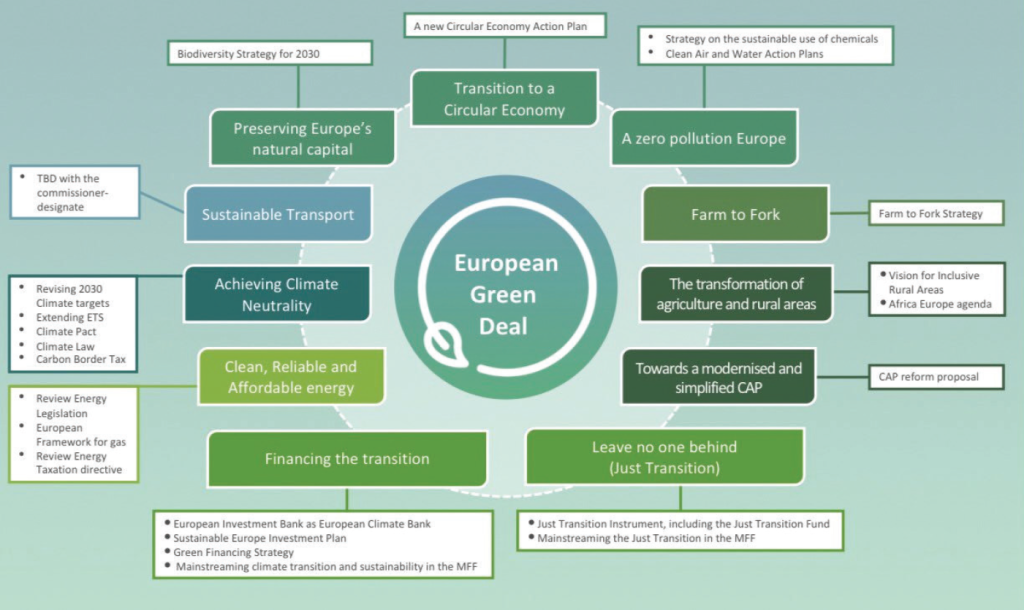

Some of the most relevant European laws and legislation related to environmental sustainability are incorporated into the European Green Deal (EGD). The EGD is a set of policies whose final aim is to lead Europe to climate neutrality by 2050. Climate neutrality means reaching a balance between GHG emissions and removals, which is expected to limit global warming. This state is known as zero emissions and can be reached if global warming is limited to 1.5°C.

The EGD includes legislative changes, with a timetable outlining when they will be enacted. The policies included in the Green Deal are presented in Figure 6 below. The most relevant policies for the fruit, vegetables and nut processing sector are the Farm to Fork Strategy, Biodiversity Strategy and Circular Economy plan. Specific legislations related to those strategies relevant for fruit, vegetable and nut processing and trade are summarised in the sections below.

Figure 5: European Green Deal aspects

Source: IFU Sustainability Report, October 2022

Organic food regulation

One of the most popular ways to go green is to produce and offer organic products. Organic food production is strongly supported by the EGD. One of the aims of the Farm to Fork Strategy is to increase the share of organic agricultural land in Europe to 25% by 2030. The consumption of imported organic food is also increasing.

If you are producing and exporting organic products to Europe, you should be aware of important new rules that may influence your business. The new EU organic regulation entered into force in 2022. The implementation of the new regulation may have a significant impact on exporters from non-European countries. Countries that have an agreement on trade in organic products with the EU will have to make changes in their organic rules in order to be recognised as compliant with the new European organic regulation.

The new organic regulation is accompanied by more than 20 secondary acts that regulate the production, control and trade of organic products in more detail. Some of the important acts to be aware of are detailed organic production rules, a list of authorised substances for plant protection and the rules on documentation requirements for imports.

Main changes implemented by the new organic regulation, relevant for the processed fruit and vegetables sector:

- Compliance with EU organic rules – If you want to export organic products to Europe, you will have to submit certificates of the authorised control body starting January 2025;

- New rules for group certification are established – In line with the new regulation, most farmer groups will have to be organised as new legal entities. The rules for group certification are also much more detailed in the new regulation. An important cost implication for your business is that a minimum of 2% sampling of products from group members will be obligatory each year;

- A longer list of authorised substances for use in processing of organic products, such as additives and processing aids;

- Flavourings must be at least 95% natural extracts;

- A list of authorised substances for disinfection and cleaning is expected to be published in 2024.

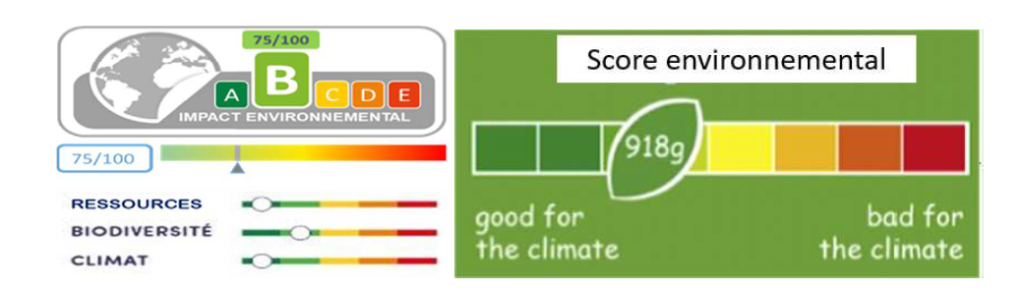

Sustainability labelling of food products

There are more than 200 environmental labels active in Europe, but not all of them are reliable in measuring environmental impact. Some companies even use non-reliable labels on purpose to give a false impression to consumers about their positive environmental impact. This unethical behaviour is called 'greenwashing'. In order to prevent greenwashing and to harmonise voluntary green claims, the European Commission published a proposal for a Directive on Green Claims in March 2023.

According to the new proposal, a green claim must be based on recognised scientific evidence, use accurate information, and take into account relevant international standards. Some of the most popular labels are Eco Score (based on Product Environmental Footprint (PEF) data), Eco Impact (based on PEF with some deviations), Planet Score (a complex algorithm including PEF) and Enviro Score (based on PEF).

The product environmental footprint methodology proposed by the EU is not fully adjusted to food production. In order to make methodology more suitable for food, the European Commission is working on a framework law on 'sustainable food systems' (including sustainability labelling). This piece of legislation is planned for Q3 2023.

Figure 6: Possible environmental labelling formats

Source: French Ecological Transition Agency (ADEME)

Deforestation-free products

In May 2023, the EU published a new regulation on deforestation-free products that will apply to large companies from 30 December 2024 and to small and medium-sized enterprises (SMEs) from June 2025. The new regulation will guarantee that cattle, wood, palm oil, soy, cocoa and coffee and their derivates exported from the EU no longer contribute to deforestation or forest degradation. It asks companies to collect precise geographical information on the land where their sourced commodities were grown so that these commodities can be checked for compliance.

Sustainable Corporate Governance

In 2022, the EU proposed the Corporate Sustainability Due Diligence Directive, aiming to endorse greater corporate responsibility and sustainability standards. The aim of this directive is to foster sustainable and responsible corporate behaviour in company operations and throughout company global value chains. This directive envisions that suppliers from developing countries will provide proof of sustainable practices, especially in relation to human rights, international labour standards and the environment.

Packaging and the Packaging Waste Directive

In November 2022, the European Commission made a proposal for a revision of EU legislation on Packaging and Packaging Waste. The main aim of the directive is that all packaging in the EU 'is reusable or recyclable in an economically viable way by 2030'. This is a practical implication for suppliers from non-European countries, as this aim includes all packaging that enters the EU.

Another proposed revision relates to the rules on food contact materials. New rules are set to improve food safety and reduce the sector’s environmental footprint.

Sustainable use of pesticides

The European Commission has adopted a proposal for a new regulation on the Sustainable Use of Plant Protection Products. The Farm to Fork strategy aims to reduce the use and risk of chemical pesticides by 50% by 2030. New measures will ensure the use of Integrated Pest Management. This is an environmentally friendly pest control system that focuses on pest prevention and prioritises alternative pest control methods, with chemical pesticides used only as a last resort.

Tips:

- Perform strict and regular controls on pesticide residues for your organic products. Due to a lack of compliance with European organic legislation, there will be increased control of some imported products.

- Read the training materials on the new organic regulation (by Alliance for Product Quality in Africa project) to prepare for the new rules on time.

- Read the short guide on Product Environmental Footprint methods (PDF) to understand the steps you should take to measure your environmental impact and reliably label your products.

- Base your sustainability claims on reliable data and approved measuring methods. Do not call your company 'carbon-neutral' if this isn't based on verifiable data[A1] [A2] . Check Frequently Asked Questions on Organic Rules to understand the specific issues relevant for your production and processing operations.

- Read the CBI study about the EU Green Deal impact on your business.

6. Incorporate green principles in your code of conduct

Developing and noting down your sustainability principles and objectives is important for improving your sustainability performance. To enhance sustainability not only for your company but also for the whole supply chain, you could also set standards for your suppliers and subcontractors. Your Code of Conduct should be based on the specific company characteristics, and can include objectives related to the following aspects:

- Reducing energy use and improving energy efficiency;

- Increasing the use of renewable energy;

- Improving logistics efficiency;

- Improving water efficiency;

- Using environmental footprint methodology to measure and reduce your environmental impact;

- Increasing the use of renewable and recyclable packaging materials;

- Reducing waste in processing operations;

- Supporting farmers in the implementation of sustainable farming methods;

- Protecting/enhancing biodiversity;

- Preventing deforestation;

- Encouraging the use of sustainable certification schemes along your supply chain (e.g. for farmers, packaging material suppliers and transport companies).

Tips:

- Use the OECD-FAO Guidance for Responsible Agricultural Supply Chains to incorporate green principles into your Code of Conduct.

- Include aspects of the ISO 14040 standard in your Code of Conduct.

7. Find funds, investors and partners that can help you become greener

There are many sustainability initiatives and projects where you can find funds or partners for a greener transition. Some of the projects are funded by international and European organisations and implemented internationally, while some projects are focused on specific countries or regions. If you are new to EU-funded projects, a good starting point is to find partners for your project implementation.

Among the most well-known European funds focused on environmental and climate action is the LIFE programme. It provides grants for environmental projects through yearly calls for proposals. Unlike many programmes that focus on public bodies only, this programme also provides funds to companies from non-European countries. To see project examples, you can use the basic or advanced search tool.

Some environmental funding projects are focused on specific regions only. For example, the UK-funded ASEAN Low Carbon Energy Programme operates in Indonesia, Malaysia, the Philippines, Thailand and Vietnam. There are many green partnerships and initiatives between Africa and Europe.

Tips:

- Read about EU funding opportunities related to agriculture and food to explore the possibilities for your green investment plans.

- Watch how to submit a proposal for European projects using the application tool.

- Use the African Food Changemakers search tool to find funding opportunities in the food and agriculture sector in Africa.

Autentika Global carried out this study on behalf of CBI.

Please review our market information disclaimer.

Search

Enter search terms to find market research